Lithium ion battery cathode material and preparation method

A technology for lithium-ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., to achieve the effects of reduced consumption, wide range of raw materials, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

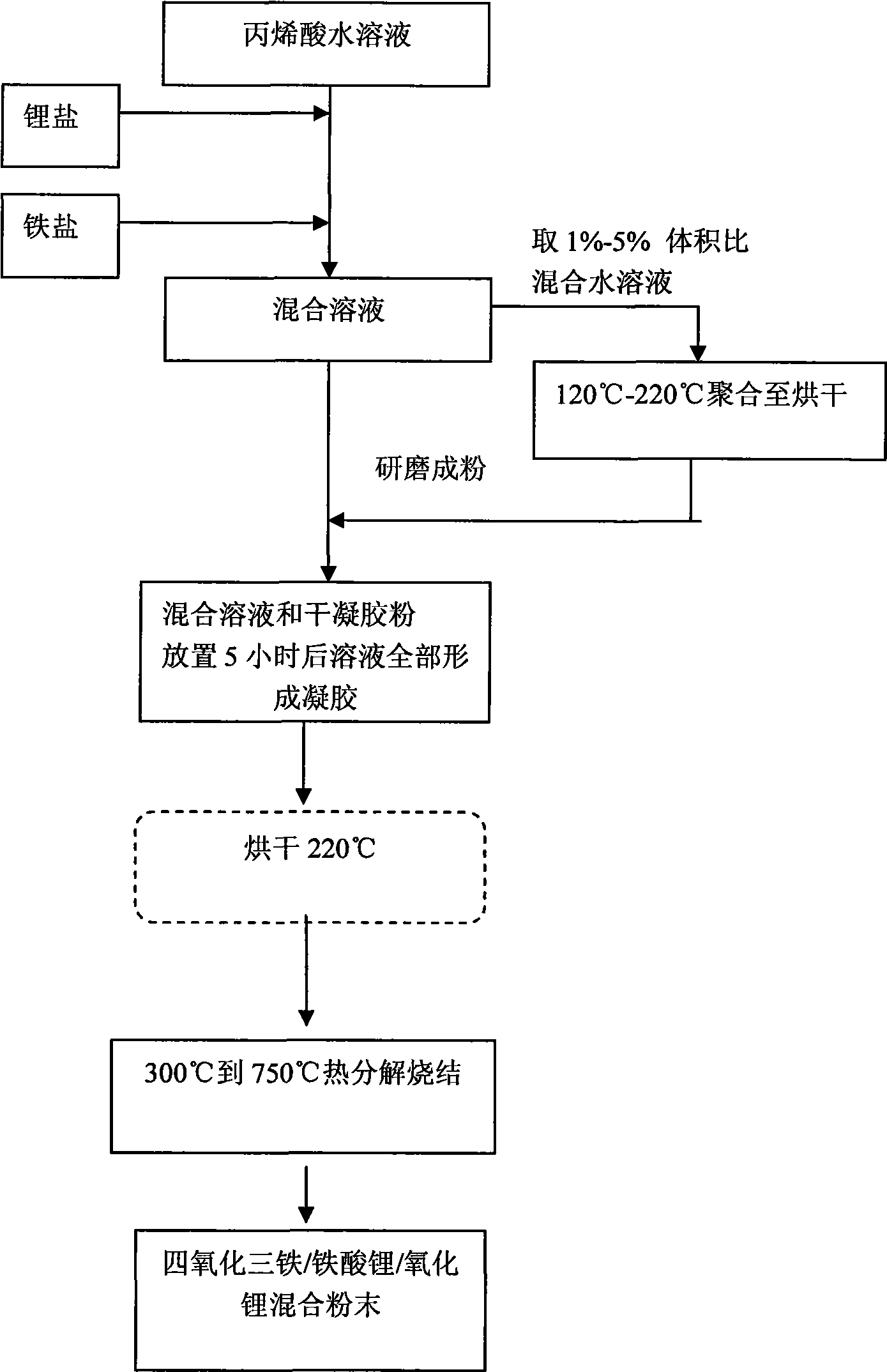

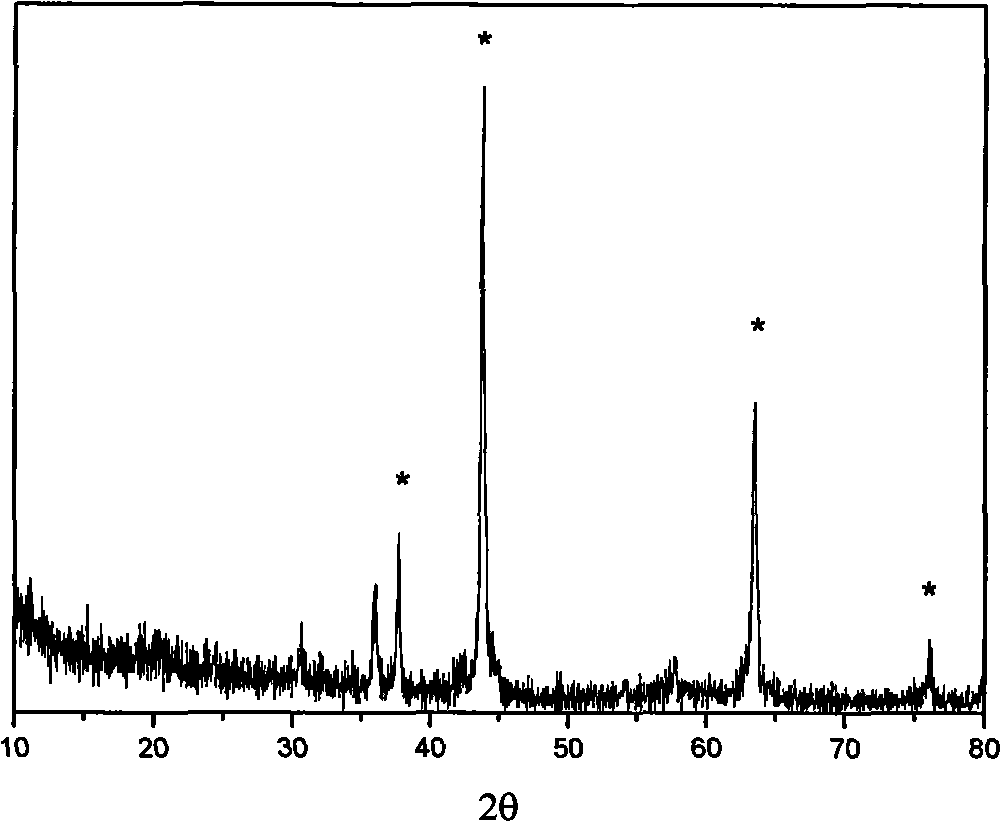

[0032] see figure 1 , respectively take 2.068g of lithium nitrate LiNO 3 and 12.12g of iron nitrate nonahydrate Fe(NO 3 ) 3 9H 2 O (that is, the molar ratio of Li:Fe is 1:1), fully dissolved in 75ml of water by stirring, then add 25ml of acrylic acid, after mixing evenly, a mixed aqueous solution is obtained, take 5ml of the mixed aqueous solution and heat and polymerize at 180°C until drying (approximately 4 hours), to obtain black xerogel, then grind to obtain xerogel powder, this xerogel powder is added in remaining 95ml mixed aqueous solution, after standing at room temperature for 5 hours, mixed aqueous solution forms gel, see figure 2 , then heated to 450°C to decompose the organic matter in the gel, and sintered for 10 hours to obtain ferric oxide / lithium ferrite / lithium oxide Fe 3 o 4 -LiFeO 2 -Li 2 O composite powder.

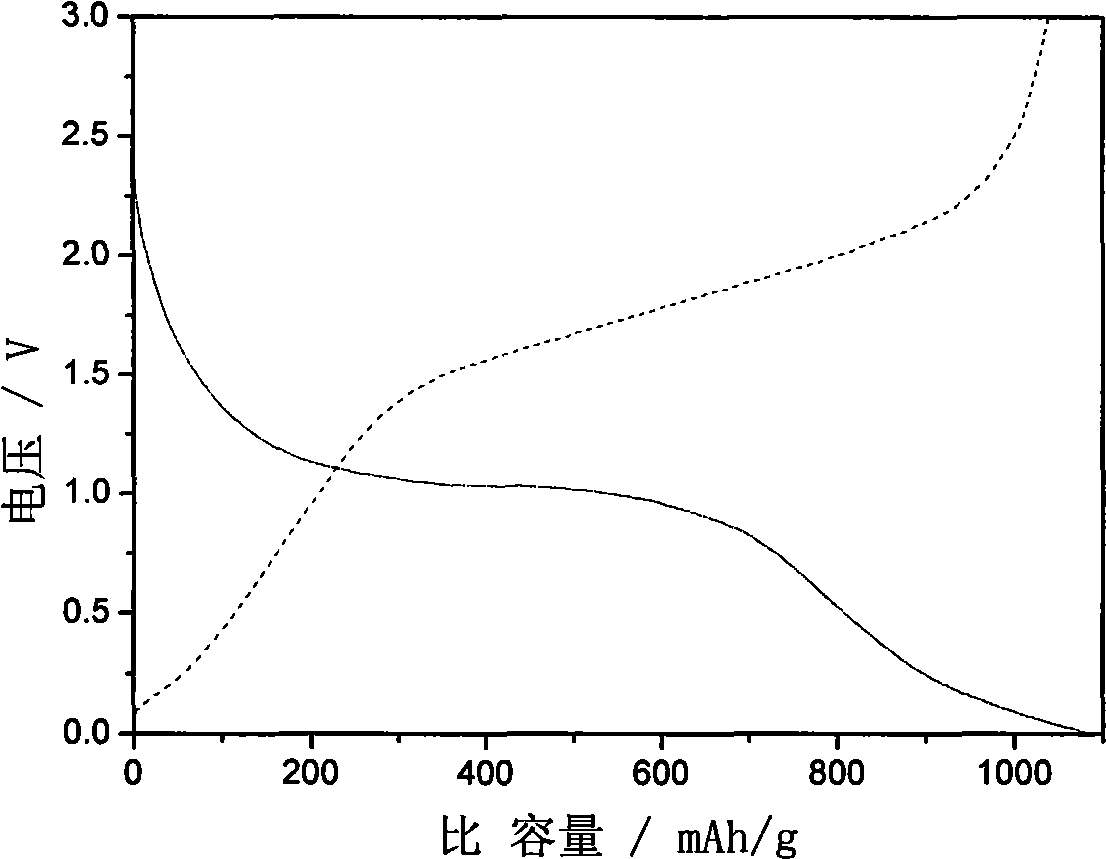

[0033] With the ferric oxide / lithium ferrite / lithium oxide Fe that embodiment 1 makes 3 o 4 -LiFeO 2 -Li 2 O composite powder is used as ...

Embodiment 2

[0036] Take 1.034g of lithium nitrate LiNO respectively 3 and 3.03g of iron nitrate nonahydrate Fe(NO 3 ) 3 9H 2 O (i.e. the molar ratio of Li:Fe is 2:1), stirred and dissolved in 75ml of water, then added 25ml of acrylic acid, after mixing evenly, a mixed aqueous solution was obtained, and 5ml of the mixed aqueous solution was heated and polymerized at 120°C until dried. Obtain black dry gel, then grind to obtain dry gel powder, add this dry gel powder to the remaining 95ml mixed aqueous solution, after 5 hours, mix the aqueous solution to form a gel, then heat to 750°C to decompose the organic matter in the gel, Sintering for 10 hours to obtain ferric oxide / lithium ferrite / lithium oxide Fe 3 o 4 -LiFeO 2 -Li 2 O composite powder, using the powder as negative electrode, the measured discharge specific capacity is greater than 1000mAh / g.

Embodiment 3

[0038] Take 0.207g of lithium nitrate LiNO respectively 3 and 12.12g of iron nitrate nonahydrate Fe(NO 3 ) 3 9H 2 O (i.e. the molar ratio of Li:Fe is 1:10), stirred and dissolved in 75ml of water, then added 25ml of acrylic acid, after mixing evenly, a mixed aqueous solution was obtained, and 5ml of the mixed aqueous solution was heated and polymerized at 220°C until drying to obtain Black dry gel, then grind to obtain dry gel powder, add the dry gel powder to the remaining 95ml mixed aqueous solution, after 5 hours, mix the aqueous solution to form a gel, then heat to 300°C to decompose the organic matter in the gel, and sinter 10 hours, obtain ferric oxide / lithium ferrite / lithium oxide Fe 3 o 4 -LiFeO 2 -Li 2 O composite powder, using the powder as negative electrode, the measured discharge specific capacity is greater than 1000mAh / g.

[0039] With the Fe that embodiment 3 makes 3 o 4 -LiFeO 2 -Li 2 O composite powder and graphite are mixed at 3:1 and 1:10 to make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com