Modified lithium ferrite positive electrode material, preparation method thereof and positive plate

A cathode material, lithium ferrite technology, applied in the direction of positive electrode, active material electrode, battery electrode, etc., can solve the problem of low battery capacity, and achieve the improvement of specific capacity, complete and orderly crystal structure, and reduction of electrode polarization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] One aspect of the present invention provides a method for preparing a modified lithium ferrite positive electrode material, comprising the following steps:

[0025] Step 1: Take LiOH·H 2 O, Fe(NO 3 ) 3 9H 2 O and Mn(CH 3 COOH) 2 4H 2 O raw materials were mixed, and dried at 100°C for 8 hours to obtain mixture A (the mixture of anhydrous lithium hydroxide, iron nitrate and manganese acetate is called mixture A); among them, LiOH·H 2 O, Fe(NO 3 ) 3 9H 2 O and Mn(CH 3 COOH) 2 4H 2 The molar ratio of Li:Fe:Mn in the O raw material is 5:0.95:0.05-5:0.85:0.15. That is, the molar ratio of Li / (Fe+Mn) is 5:1.

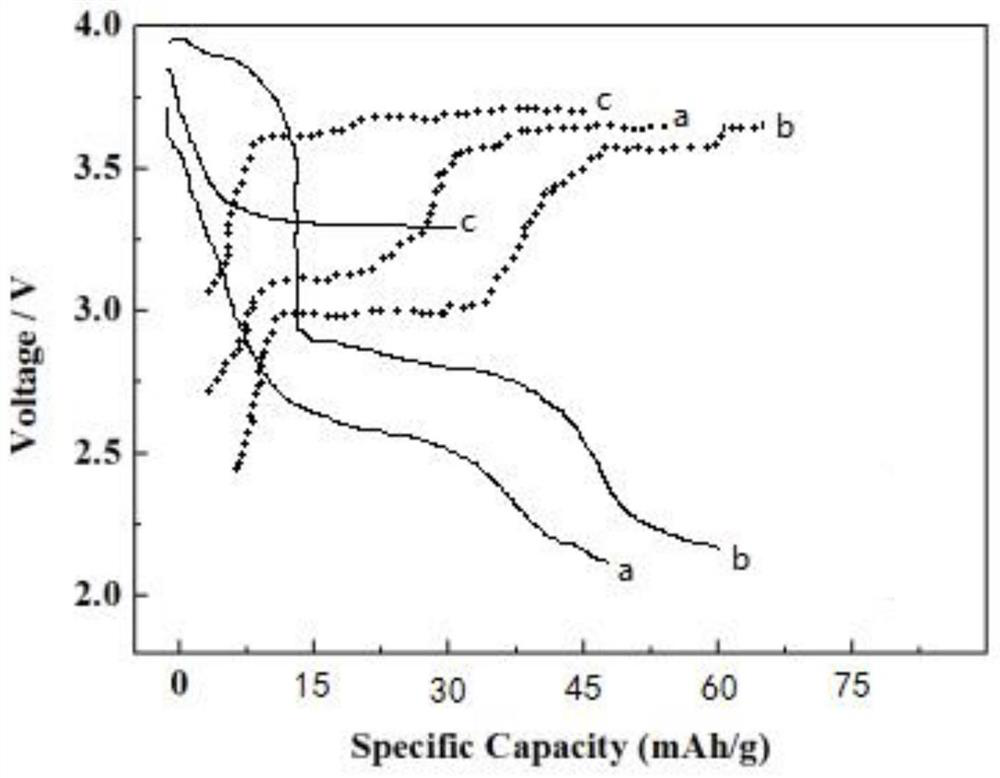

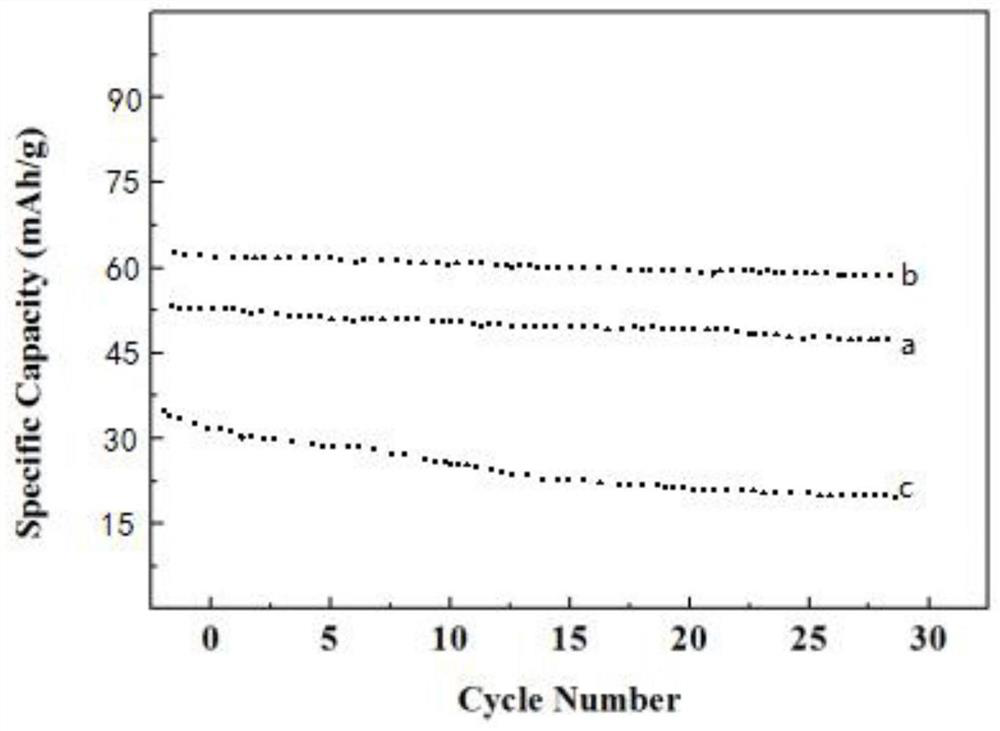

[0026] LiOH·H 2 O as lithium source, Fe(NO 3 ) 3 9H 2 O is used as the iron source, and carbon powder is used to protect it during the roasting process without gas protection, and the antifluorite-type Li 5 FeO 4 . After Li 5 FeO 4 The microscopic morphology of the samples was observed, and the Li 5 FeO 4 The X-ray diffraction pattern, compared wit...

Embodiment 1

[0039] LiOH·H 2 O, Fe(NO 3 ) 3 9H 2 O, Mn(CH 3 COOH) 2 4H 2 O raw materials were mixed at a molar ratio of 5:0.85:0.15, and dried at 100°C for 8 hours to obtain a precursor;

[0040] The above-mentioned Li 5 Fe 0.85 mn 0.15 o 4 sample;

Embodiment 2

[0042] LiOH·H 2 O, Fe(NO 3 ) 3 9H 2 O, Mn(CH 3 COOH) 2 4H 2 O raw materials were mixed at a molar ratio of 5:0.90:0.10, and dried at 100°C for 8 hours to obtain a precursor;

[0043] The above-mentioned Li 5 Fe 0.90 mn 0.10 o 4 sample;

[0044] in Li 5 Fe 0.90 mn 0.10 o 4 Add 9% CNT to the sample for mixing and grinding to obtain Li 5 Fe 0.90 mn 0.10 o 4 / CNT composite cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com