Chemical compound batteries with embedded lithium ferrate-lithium

A technology of intercalation compound, lithium ferrate, applied in the synthesis of lithium ferrate cathode material for lithium ion battery, lithium ferrate-lithium intercalation compound battery field, can solve problems such as instability and difficulty, and achieve high specific energy and price. Low, uncomplicated equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Accurately Weighing Li by Stoichiometric Ratio 2 O and Fe 2 o 3 After mixing, mechanical ball milling was carried out for 10 hours under the condition that the mass ratio of ball to material was 2.0:1 and the rotational speed was 250rmp / min, so as to obtain a highly active reaction mixture. Then, in an ozone atmosphere, the temperature was kept at 500° C. for 10 hours to obtain the product lithium ferrate, which was analyzed to have a purity of 95% and a particle size of 100 nm.

Embodiment 2

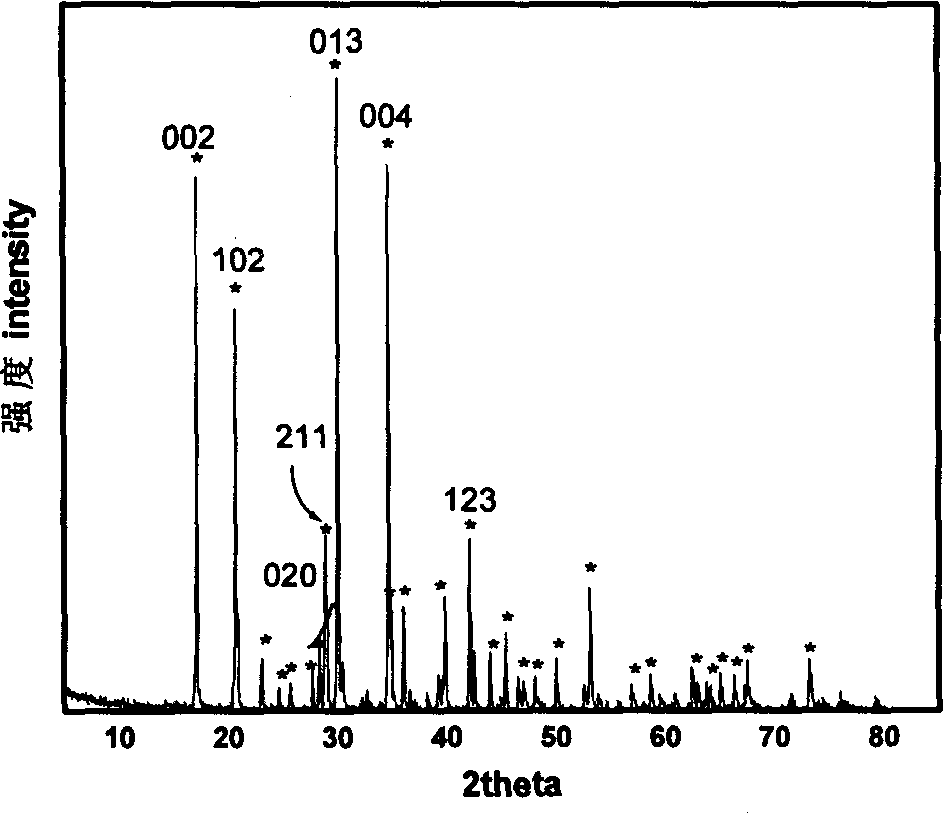

[0026] Accurately Weighing Li by Stoichiometric Ratio 2 O and Fe 2 o 3 After mixing, mechanical ball milling was carried out for 20 hours under the condition that the mass ratio of ball to material was 2.5:1 and the rotational speed was 350rmp / min, so as to obtain a highly active reaction mixture. Then, in an ozone atmosphere, the temperature was kept at 500° C. for 10 hours to obtain the product lithium ferrate, which was analyzed to have a purity of 97% and a particle size of 70 nm. Fig. 1 is the powder X-ray diffraction diagram of the lithium ferrate obtained in Example 2.

Embodiment 3

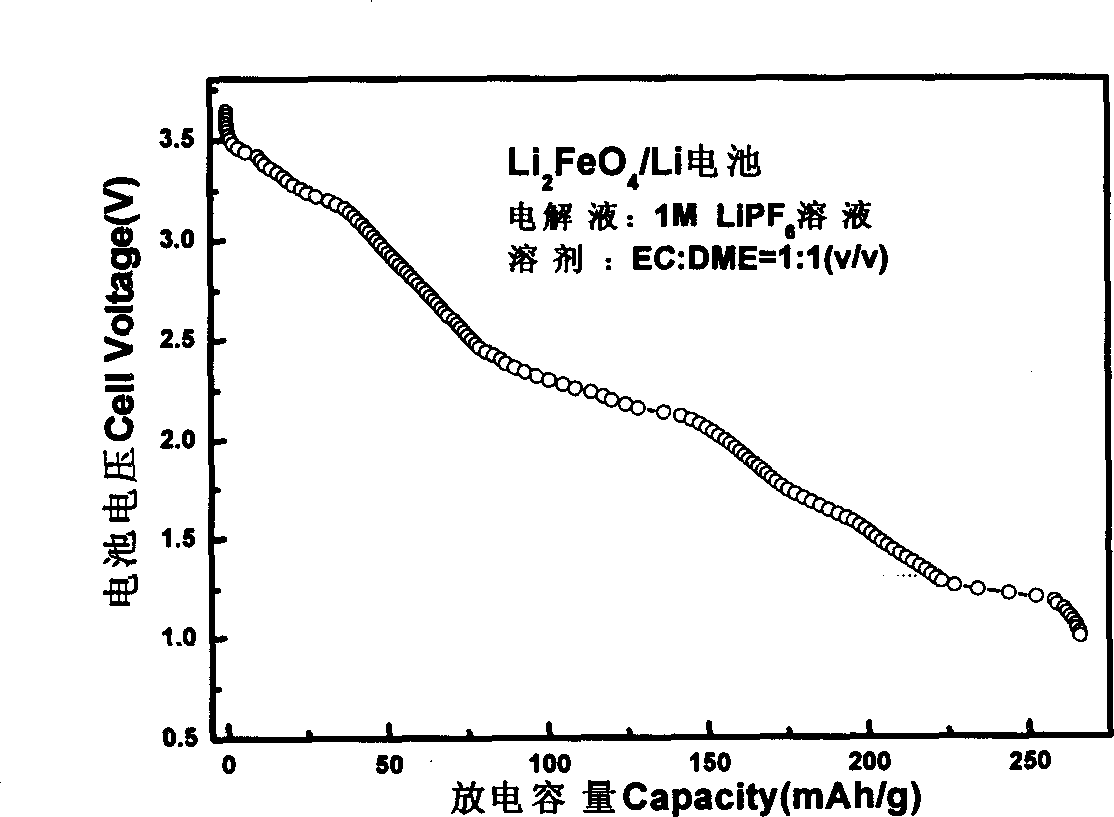

[0028] The lithium ferrate product obtained in Example 2 is uniformly mixed with acetylene black and PTFE in a ratio of 85%: 10%: 5% by weight, isopropanol is used as a dispersant, and roll molding is performed to obtain a positive pole piece with a thickness of 0.12mm. With 3 times the C of the positive electrode capacity 6 Li is assembled into a lithium ferrate-lithium intercalation compound battery as the negative electrode. The electrolyte solution is 1MLiPF 6 solution (solvent is EC:DME=1:1v / v), and the diaphragm is polypropylene microporous membrane ( cellgard2300 ). The test was carried out with a constant current of 0.2C, a cut-off voltage of 1.0V, and a positive electrode discharge capacity of nearly 270mAh / g. The discharge curve is shown in Figure 2, and Figure 2 is LiFeO 4 / Li battery discharge curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com