Graphene modification current collector prepared by employing plasma-assisted chemical vapor deposition and preparation method thereof

An auxiliary gas and graphene technology, applied in the field of electrochemical energy storage, can solve the problems of graphene dispersion and processing, the influence of graphene coating conductivity, and cumbersome preparation methods, so as to improve high power performance and cycle Stability and life, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

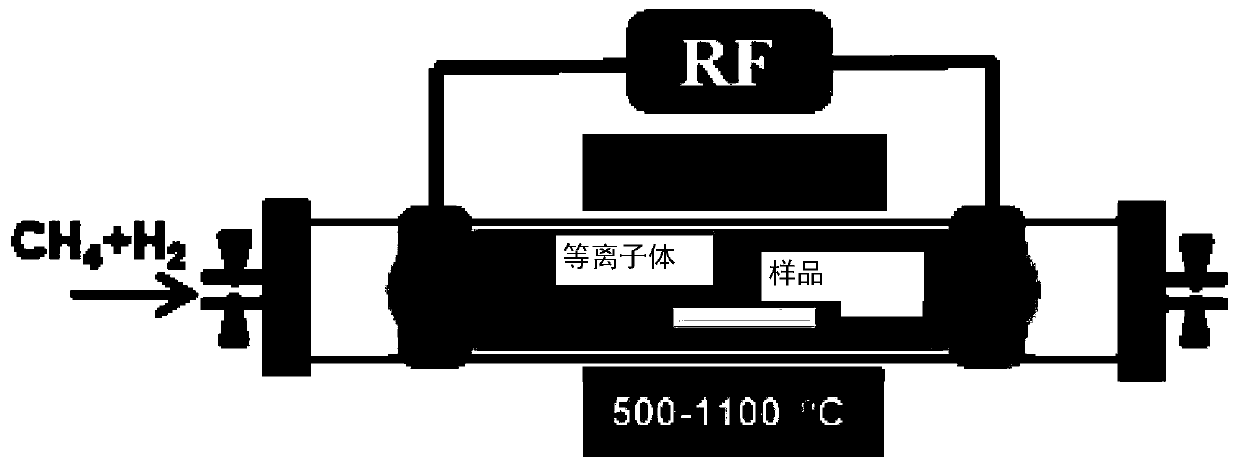

[0034] Preparation of graphene aluminum foil current collector:

[0035] First, place the glass substrate in a tube furnace and pass H 2 (20sccm) and turn on the vacuum pump, start heating when the air pressure is 30Pa, the tube furnace heats up at a heating rate of 10°C / min, and after reaching the predetermined reaction temperature of 600°C, turn on the RF power supply, adjust the power supply to 300W, and generate hydrogen plasma in the quartz tube ; followed by CH 4 (5sccm), grow one deck graphene on aluminum foil surface after reacting 60min; Graphene film thickness is about 900nm.

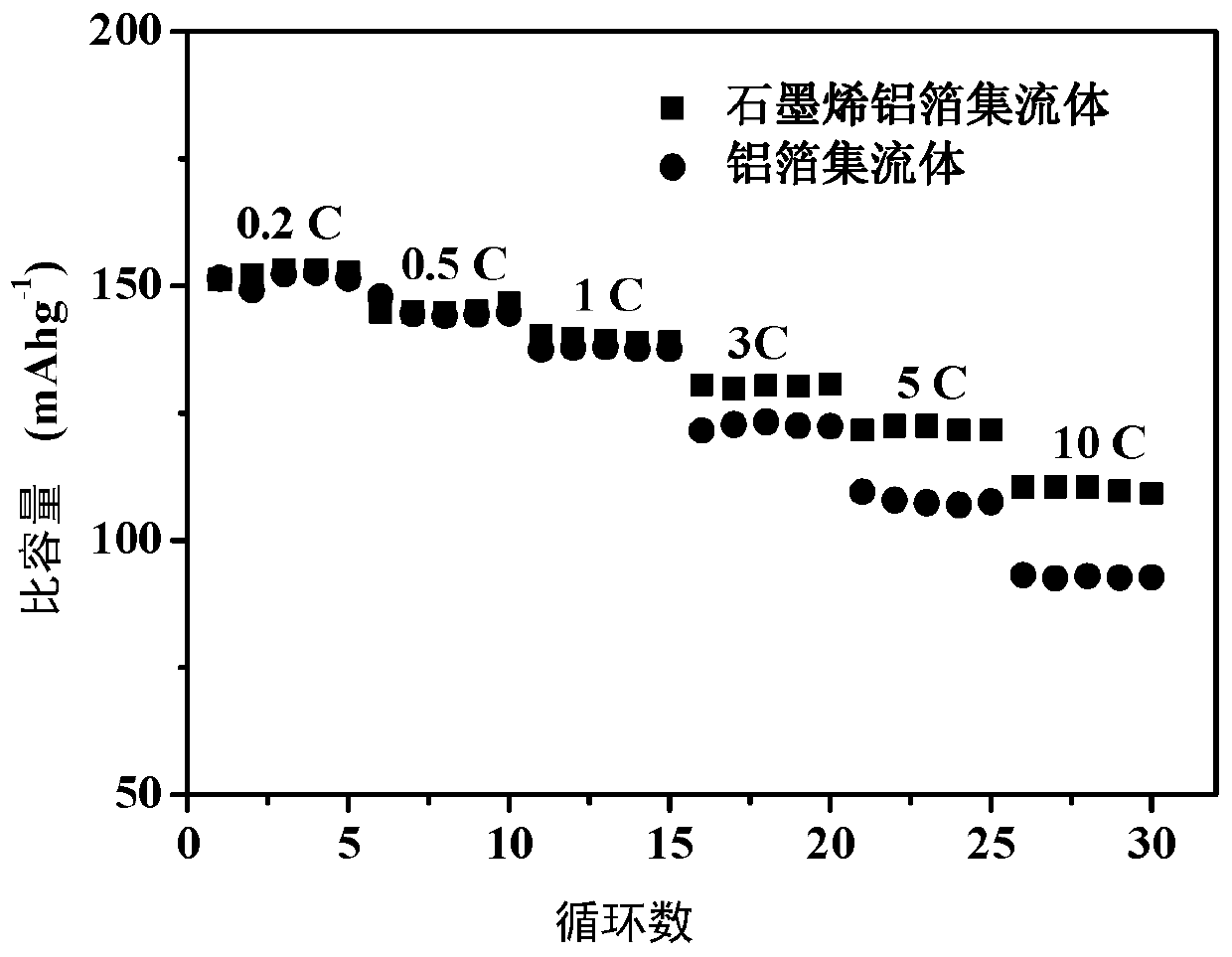

[0036] The graphene-modified aluminum foil current collector of this embodiment is assembled into a button battery with a conventional aluminum foil current collector for rate performance test comparison (see image 3 ). Specifically, assembling the graphene aluminum foil current collector (or conventional aluminum foil current collector) obtained in this embodiment into a button battery in...

Embodiment 2

[0038] The preparation method is basically the same as in Example 1, and the difference is: in step (1), hydrogen H 2 (10 sccm), CH 4 (10sccm), the power supply is 200W, and the reaction is 20min. The prepared graphene film thickness is 300nm.

Embodiment 3

[0040] The preparation method is basically the same as in Example 1, and the difference is: in step (1), hydrogen H 2 (5 sccm), CH 4 (1sccm), power supply is 200w, reacts 30min; The graphene film thickness of preparation is 300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com