Metal bipolar plate and preparation method thereof and fuel cell

A metal bipolar plate and metal substrate technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of limited pore sealing ability inside the corrosion-resistant coating, achieve strong binding ability, improve corrosion resistance, and reduce contact The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

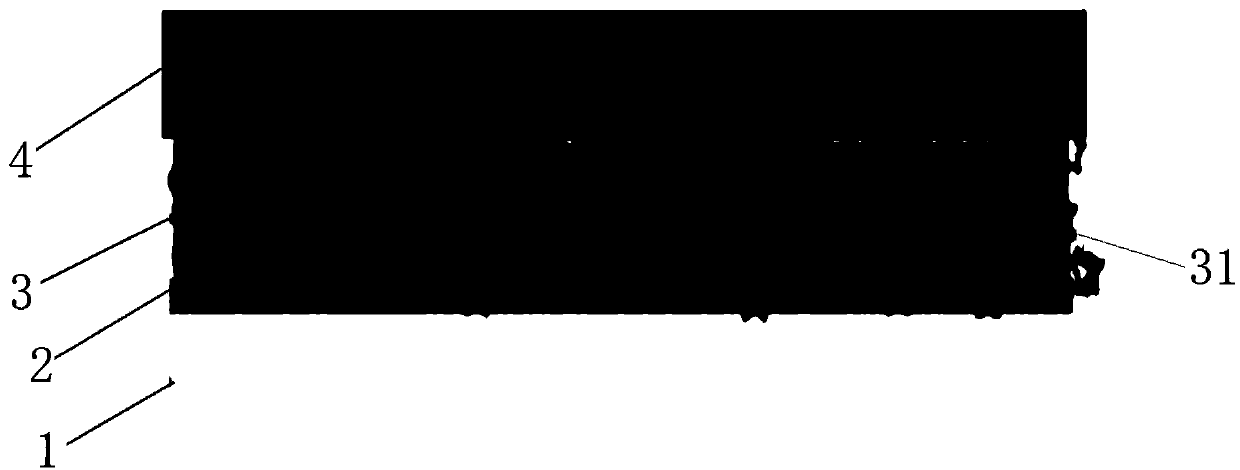

[0068] Such as Figure 1 to Figure 3 As shown, this embodiment provides a metal bipolar plate, wherein the metal bipolar plate includes: a metal substrate 1, a conductive coating 2 and a corrosion-resistant coating 3; wherein the conductive coating 2 is deposited on the metal substrate 1 . A corrosion-resistant coating 3 is deposited on the conductive coating 2 . Wherein, the material of the conductive coating 2 is conductive metal oxide.

[0069] The metal bipolar plate provided by the present embodiment deposits a layer of conductive coating 3 between the corrosion-resistant coating 3 and the metal substrate 1, and the conductive coating 3 is selected from metal oxide; The metal oxide is used as a primer to improve the bonding force between the coating and the metal substrate 1 (the inventor first discovered that the conductive metal oxide layer has a stronger bonding ability with the metal substrate, which is stronger than the bonding ability between the corrosion-resista...

Embodiment 2

[0074] Preferably, this embodiment provides a metal bipolar plate, compared with the previous embodiment, such as Figure 1 to Figure 3 As shown, the present embodiment further designs the corrosion-resistant coating as follows:

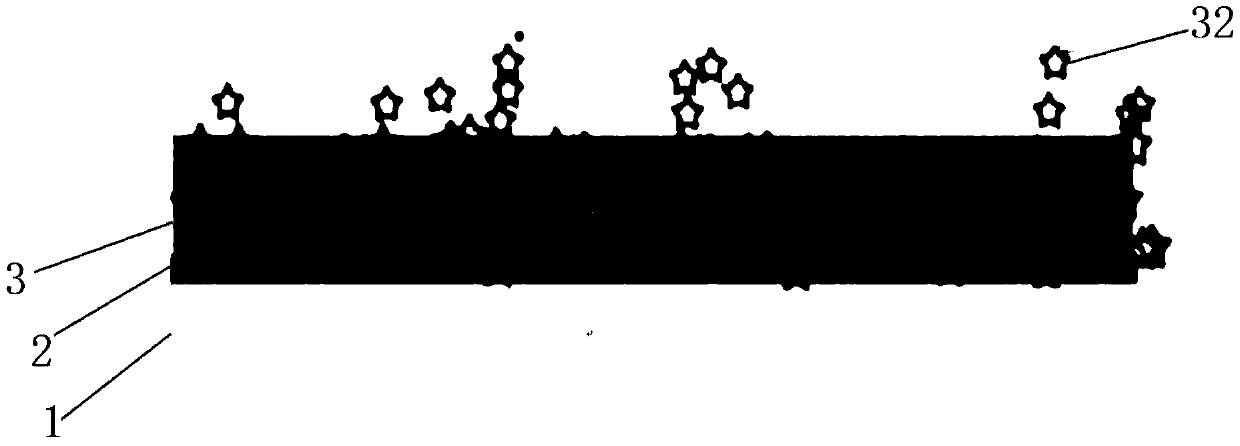

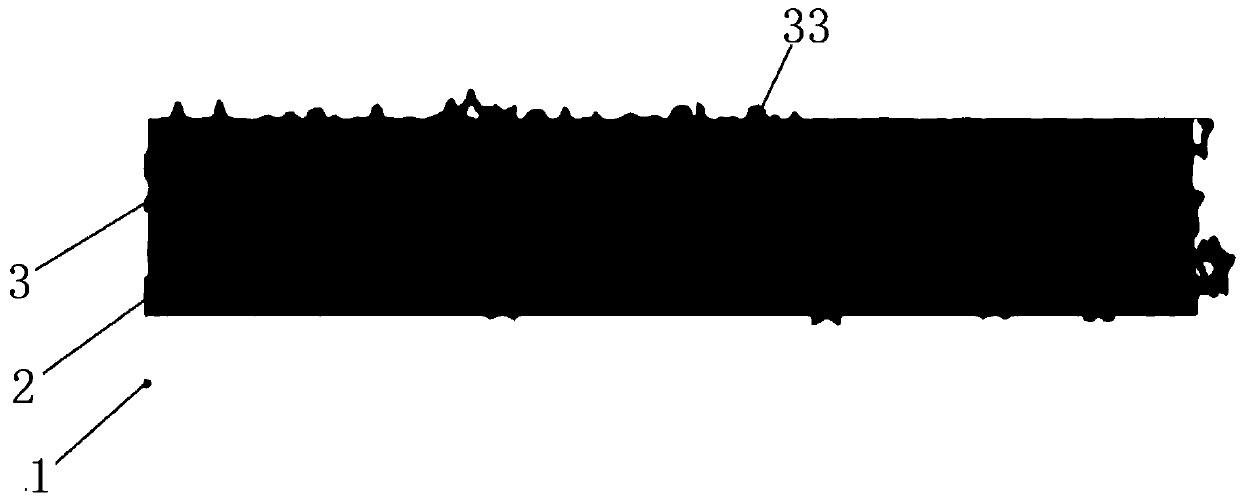

[0075] The composition of the corrosion-resistant coating 3 in this embodiment includes a first metal (preferably, the first metal includes one or more of titanium, chromium, tungsten, nickel, aluminum, copper); wherein, the corrosion-resistant coating The layer has a plurality of first pinholes distributed on the surface and inside of the corrosion-resistant coating, and the first pinholes are blocked by the oxide 31 formed by the first metal.

[0076] Here, due to the inherent defect of the physical vapor deposition method, it will cause pinholes in the deposition layer (for the repair of pinholes, the prior art also mentions self-repairing and oxidation sealing methods, but these sealing measures mainly It is aimed at the defects on the surface o...

Embodiment 3

[0080] Preferably, this embodiment provides a metal bipolar plate, compared with the above embodiments, such as figure 1 As shown, the metal bipolar plate in this embodiment also includes an amorphous carbon film 4 ; wherein the amorphous carbon film 4 is deposited on the corrosion-resistant coating 3 .

[0081] Preferably, the SP in the amorphous carbon film 4 2 The mass fraction of hybridized carbon is 60-90%; preferably, the SP in the amorphous carbon film 4 3 The mass fraction of hybridized carbon is 5-8%, and the balance is hydrogen.

[0082] Preferably, the thickness of the amorphous carbon film is 50 nm˜5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com