Mixed resin and preparation method thereof

A technology of mixed resin and ion exchange resin, which is applied in the field of mixed resin and its preparation, can solve problems such as copper corrosion and internal cooling water conductivity exceeding the standard, and achieve the effect of strong operability and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

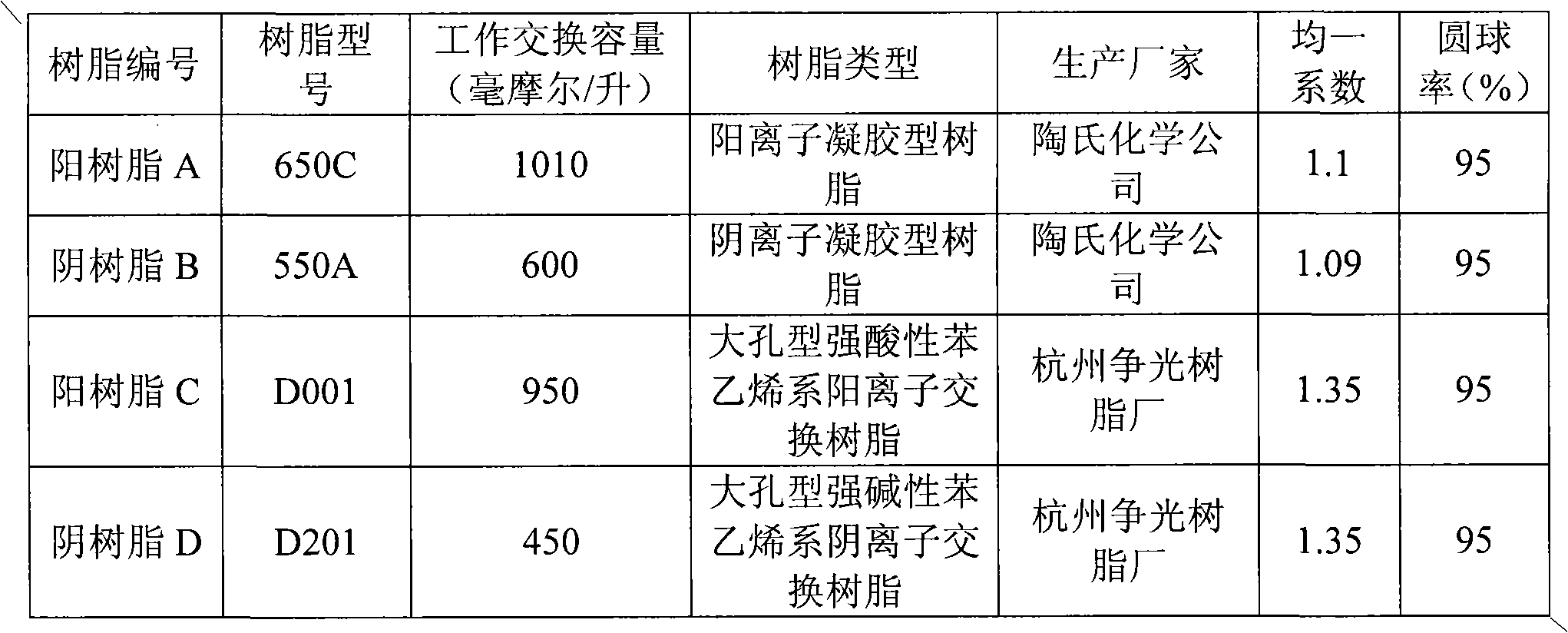

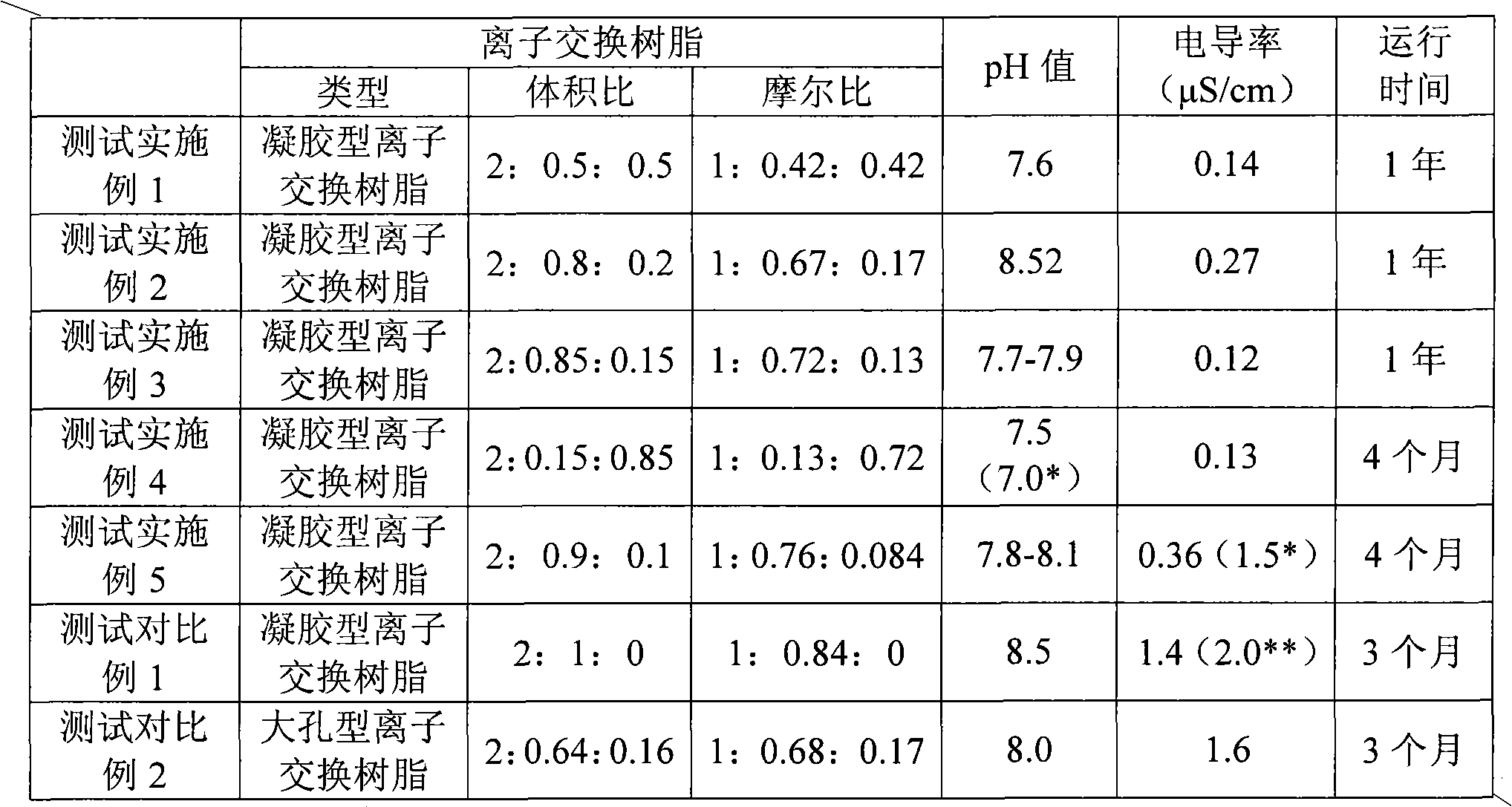

[0034] According to the method for preparing the mixed resin of the present invention, the gel-type ion exchange resin is preferably a gel-type styrene-based ion exchange resin.

[0035] The working exchange capacity of the OH type ion exchange resin, Na type ion exchange resin and H type ion exchange resin and the volume ratio among the OH type ion exchange resin, Na type ion exchange resin and H type ion exchange resin are not particularly limited.

[0036] Preferably, the working exchange capacity of described OH type ion exchange resin, Na type ion exchange resin and H type ion exchange resin and the volume ratio of described OH type ion exchange resin, Na type ion exchange resin and H type ion exchange resin make The molar ratio of the ion exchange group in the OH type ion exchange resin, the ion exchange group in the Na type ion exchange resin and the ion exchange group in the H type ion exchange resin is 1: 0.1-0.8: 0.08-0.75 .

[0037] More preferably, the working exc...

preparation example 1

[0052] Carry out pretreatment to cation resin A by following method:

[0053] The cation resin A that rinses clean with desalinated water is soaked 8 hours with the NaOH solution of 5% by weight for twice the concentration of this cation resin volume, then rinses with desalinated water until the water quality is transparent and clear and free of phenolphthalein alkalinity; After soaking in HCl solution with a concentration twice the volume of the cation resin of 5% by weight for 8 hours, rinse with desalinated water until the water quality is transparent and clear, the methyl orange indicator is added dropwise and the indicator turns yellow and the conductivity is ≤ 1.0 μS / cm.

preparation example 2

[0055] This preparation example is used for transforming H-type ion exchange resin into Na-type ion exchange resin.

[0056] Adopt the H type ion-exchange resin obtained by preparation example 1, soak 24 hours with the NaOH solution of 5% by weight with twice the concentration of the resin volume, then rinse with desalinated water until the water quality is transparent and clear, without phenolphthalein alkalinity and conductivity ≤1.0μS / cm, thus transforming H-type ion exchange resin into Na-type ion exchange resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com