Method for preparing silver metal oxide electrical contact material through internal oxidation method to improve welding-resistant performance

A technology of oxide electrical and contact materials, which is applied in the direction of contacts, circuits, and electrical switches, and can solve the problems of improving the anti-welding performance of unsuitable materials, reducing the electrical conductivity of electrical contact materials, and not improving the anti-welding performance. , to achieve the effect of improving the anti-welding performance, reducing the welding force and reducing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

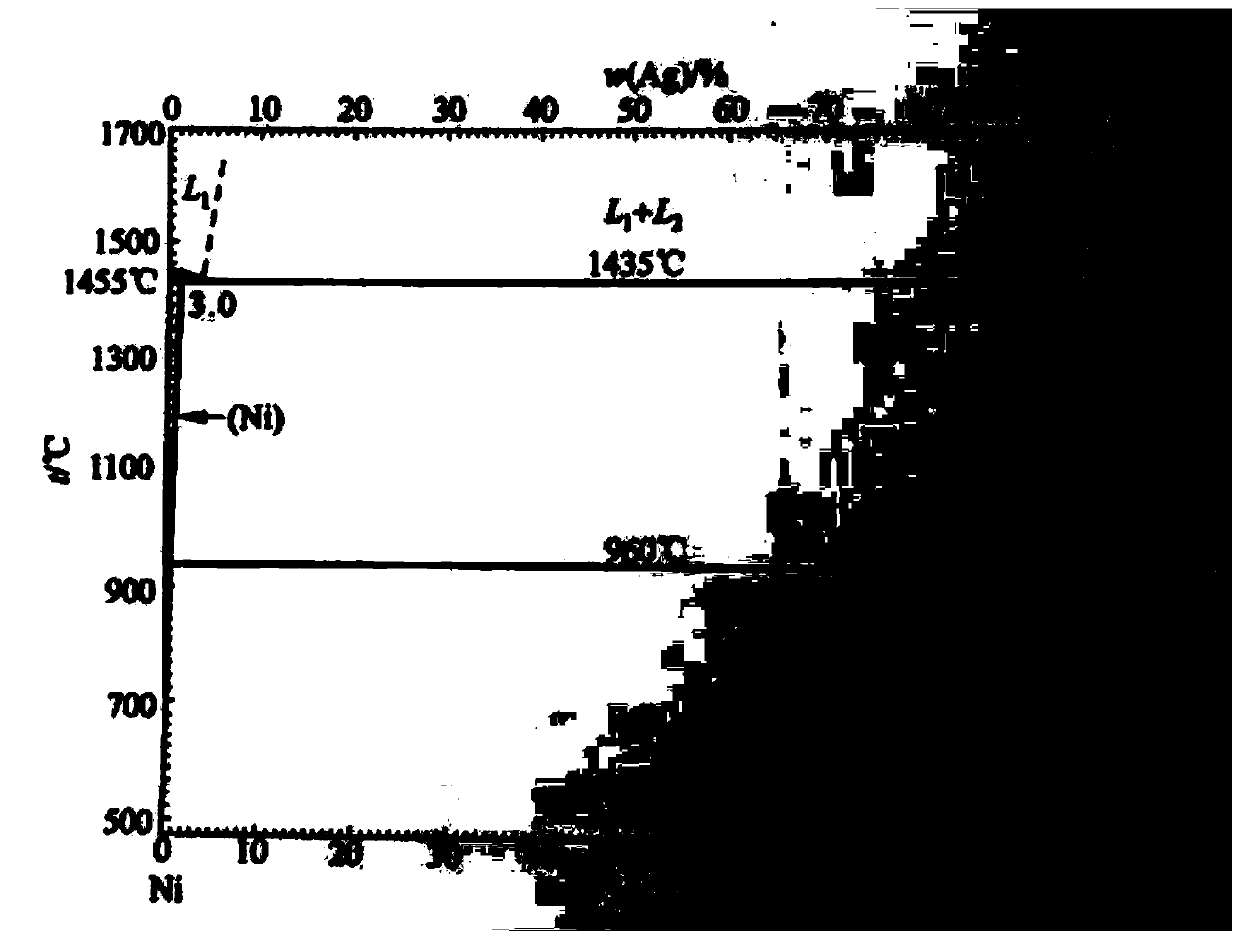

Image

Examples

Embodiment 1

[0031] a) 17.6kg silver plates are melted in a graphite crucible to form a silver melt;

[0032] b) The temperature of the silver melt is increased to 1300°C, and 0.2kg of nickel powder is added;

[0033] c) sufficient stirring to form a homogenized alloy melt;

[0034] d) The temperature of the silver alloy melt is lowered to 1050°C, 2.2kg of cadmium ingots and additives are added, and the alloy is fully stirred to form an alloy;

[0035] e) AgCd10.5 alloy is cast into a round ingot, and the mass percentage of nickel element in the alloy ingot is 1%;

[0036] f) After extrusion, hot rolling, cold rolling, punching, internal oxidation and other processes, it is processed into internal oxidation AgCdO (12) sheet contacts.

Embodiment 2

[0038] a) 17.28kg silver plates are melted in a graphite crucible to form a silver melt;

[0039] b) The temperature of the silver melt is increased to 1250°C, and 0.8kg of AgNi10 alloy is added;

[0040] c) sufficient stirring to form a homogenized alloy melt;

[0041] d) The temperature of the silver alloy melt is lowered to 1100° C., adding 1.26 kg of tin ingot and 0.66 kg of indium ingot, and fully stirring to form an alloy;

[0042]e) AgSn6.3In3.3 alloy is cast into a round ingot, and the mass percentage of nickel element in the alloy ingot is 0.4%;

[0043] f) After extrusion, drawing, internal oxidation, secondary extrusion and other processes, it is processed into internal oxidation AgSnO 2 (8)In 2 o 3 (4) wire.

Embodiment 3

[0045] a) 18.26kg silver plates are melted in a graphite crucible to form a silver melt;

[0046] b) The temperature of the silver melt is increased to 1300°C, and 0.14kg of nickel powder is added;

[0047] c) sufficient stirring to form a homogenized alloy melt;

[0048] d) The temperature of the silver alloy melt is lowered to 1050° C., adding 1.6 kg of zinc ingot, and fully stirring to form an alloy;

[0049] e) AgZn8 alloy is cast into a round ingot, and the mass percentage of nickel element in the alloy ingot is 0.7%;

[0050] f) After extrusion, hot rolling, cold rolling, punching, internal oxidation and other processes, it is processed into internal oxidation AgZnO (10) sheet contacts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com