3D printing wire rod with pearl effect and preparation method thereof

A 3D printing and pearlescent effect technology, applied in the direction of additive processing, etc., can solve problems such as plugging, secondary processing dispersion, material performance degradation, etc., and achieve a good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

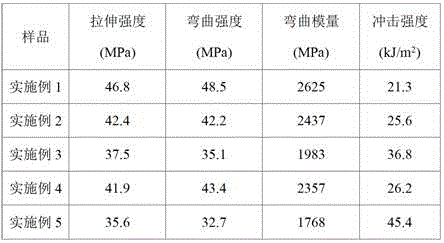

Examples

Embodiment 1

[0040] 1. A 3D printing wire with a pearlescent effect, characterized in that: according to the weight percentage formula:

[0041] PLLA (refractive index 1.40, number average molecular weight 65000) 70

[0042] SEBS (refractive index 1.50) 25

[0043] PLA-g-GMA 3

[0044] Antioxidant 168 1

[0045] white oil 1.

[0046] 2. The method for preparing the above-mentioned 3D printing wire having a pearlescent effect comprises the following steps:

[0047] A. Dry PLLA, SEBS, PLA-g-GMA, and antioxidant 168 in a drying oven for 12 hours;

[0048] B. According to the proportioning by weight percentage, take the dried PLLA, SEBS, PLA-g-GMA, antioxidant 168, white oil;

[0049] C. each component after weighing is placed in high-speed kneader high-speed mixing 10min, and the rotating speed of described high-speed mixer is 1000rpm;

[0050] D. Put the above-mentioned fully mixed and uniform raw materials into the screw extruder, heat them at a high temperature of 130-210°C, melt and p...

Embodiment 2

[0056] 1. A 3D printing wire with a pearlescent effect, characterized in that: according to the weight percentage formula:

[0057] PLLA (refractive index 1.42, number average molecular weight 85000) 60

[0058] TPV (refractive index 1.53) 30

[0059] POE-g-MAH 7

[0060] Antioxidant 1010 1.5

[0061] white oil 1.5.

[0062] 2. The method for preparing the above-mentioned 3D printing wire having a pearlescent effect comprises the following steps:

[0063] A. Dry PLLA, TPV, POE-g-MAH, and antioxidant 1010 in a drying oven for 12 hours;

[0064] B. According to the proportioning by weight percentage, weigh the dried PLLA, TPV, POE-g-MAH, antioxidant 1010, white oil;

[0065] C. each component after weighing is placed in the high-speed kneader high-speed mixing 5min, and the rotating speed of described high-speed mixer is 1500rpm;

[0066] D. Put the above-mentioned fully mixed and uniform raw materials into the screw extruder, heat them at a high temperature of 130-210°C, ...

Embodiment 3

[0072] 1. A 3D printing wire with a pearlescent effect, characterized in that: according to the weight percentage formula:

[0073] PDLA (refractive index 1.35, number average molecular weight 90000) 40

[0074] TPB (refractive index 1.52) 50

[0075] POE-g-GMA 9

[0076] Antioxidant 626 0.5

[0077] White oil 0.5.

[0078] 2. The method for preparing the above-mentioned 3D printing wire having a pearlescent effect comprises the following steps:

[0079] A. Dry PDLA, TPB, POE-g-GMA, and antioxidant 626 in a drying oven for 12 hours;

[0080] B. According to the ratio by weight percentage, take the dried PDLA, TPB, POE-g-GMA, antioxidant 626, white oil;

[0081] C. each component after weighing is placed in high-speed kneader high-speed mixing 5min, and the rotating speed of described high-speed mixer is 1200rpm;

[0082] D. Put the above-mentioned fully mixed and uniform raw materials into the screw extruder, heat them at a high temperature of 130-210°C, melt and plastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com