Method for performing water purification plant advanced treatment by using submerged ultrafiltration membrane

An advanced treatment and ultrafiltration membrane technology, applied in the field of water treatment, can solve the problems of high content of suspended solids and turbidity in the effluent, the system is not resistant to impacts on the effluent water quality, and the complete set of equipment occupies a large area, achieving less dehydration facilities and automation The effect of high degree and convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

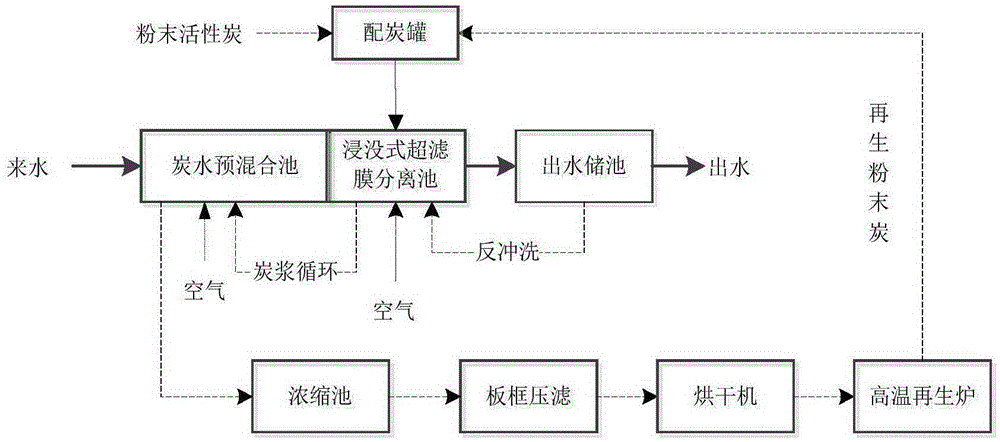

Image

Examples

Embodiment 1

[0046] In this example, a city waterworks uses "coagulation-sedimentation-submerged ultrafiltration membrane treatment system-disinfection-water distribution" to treat raw water. After precipitation, the turbidity of the effluent is 3.58NTU, and the CODmn is 5.4mg / L , DOC is 4.76mg / L, a pilot test is conducted for the effluent of the sedimentation tank of the plant, and the scale of the pilot test is 200m 3 / d. Its process parameters are as follows:

[0047] (1) Dosing amount of activated carbon: The average daily amount of carbon added is about 125mg / L.

[0048](2) Carbon discharge: The carbon discharge frequency of the pilot test is once a day, 1 to 2 hours each time, the carbon discharge is about 0.5m3 / d, the concentration is 24g / L, and the carbon discharge and carbon addition are in balance.

[0049] (3) Carbon slurry circulation in the submerged ultrafiltration membrane separation tank: the carbon slurry circulation is 1.5 times of the influent flow.

[0050] (4) Carbo...

Embodiment 2

[0060] In this example, a waterworks in a city uses "coagulation-sedimentation-submerged ultrafiltration membrane treatment system-disinfection-water distribution" to treat raw water. After precipitation, the turbidity of the effluent is 4.94NTU, and the CODmn is 5.8mg / L , the DOC is 5.27mg / L, and the pilot test is carried out for the effluent of the sedimentation tank of the plant. The scale of the pilot test is 200m 3 / d. Its process parameters are as follows:

[0061] (1) Dosing amount of activated carbon: The average daily amount of carbon added is about 150mg / L.

[0062] (2) Carbon discharge: The carbon discharge frequency of the pilot test is once a day, 1 to 2 hours each time, the carbon discharge is about 0.9m3 / d, the concentration is 33.4g / L, and the carbon discharge and carbon addition are in balance.

[0063] (3) Carbon slurry circulation in the submerged ultrafiltration membrane separation tank: the carbon slurry circulation is twice the influent flow.

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com