Pollution soil steam treatment method and apparatus

A technology of polluted soil and treatment method, applied in soil steam disinfection, restoration and application of polluted soil, etc., can solve the problems of large energy consumption, high energy consumption, blocked pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

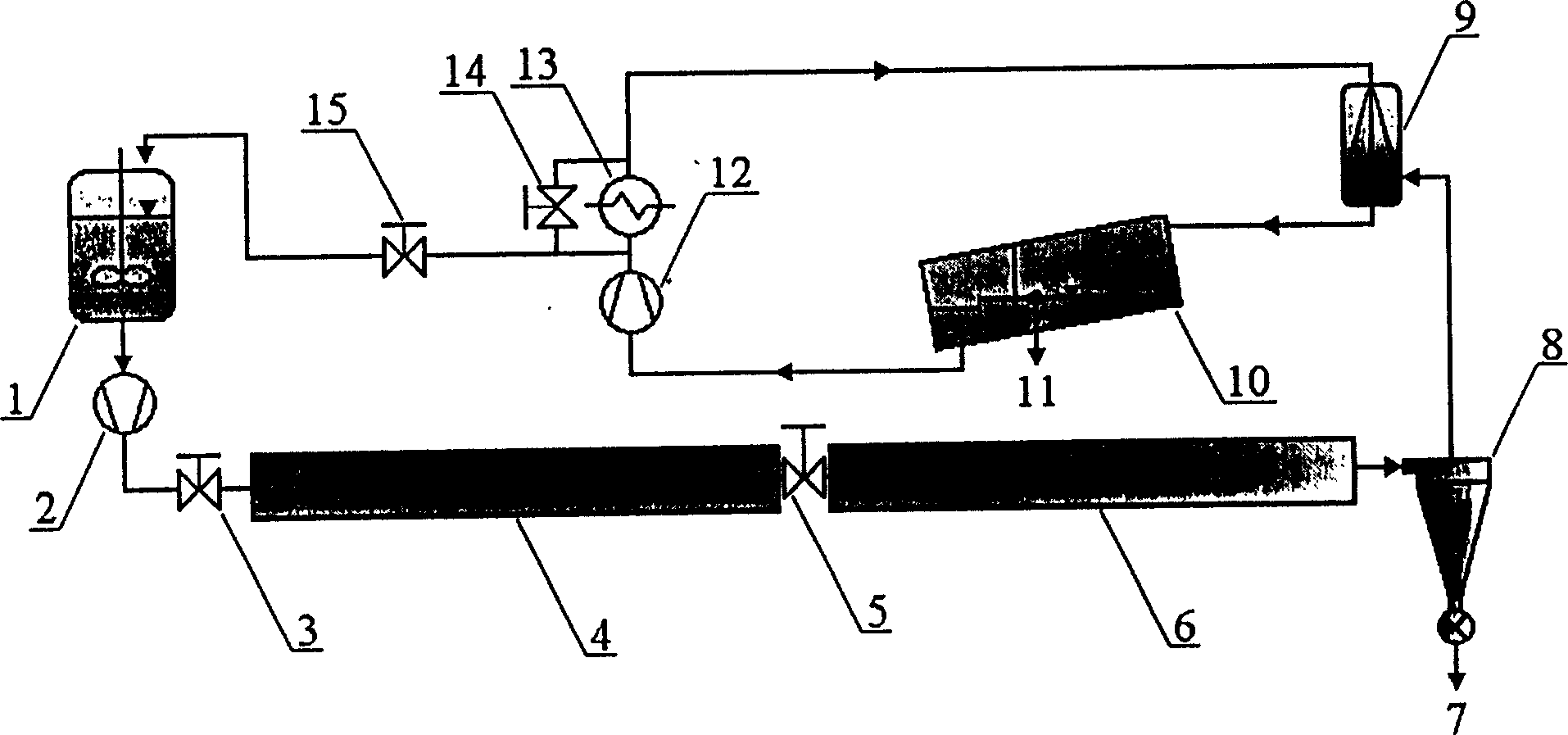

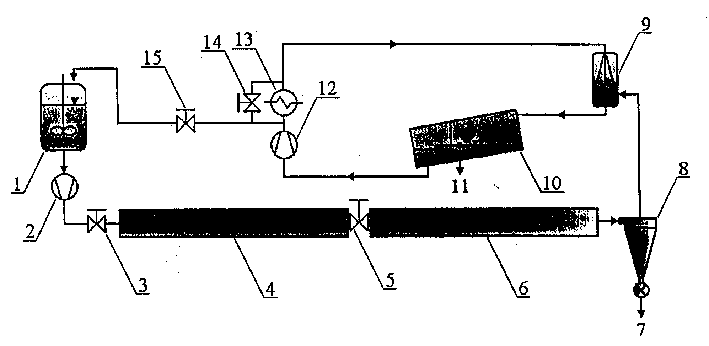

[0013] Embodiments of the present invention are described in conjunction with the accompanying drawings. Depend on figure 1 As shown, the contaminated soil steam treatment device consists of a stirring container 1, a mud pump 2, a flow control valve 3, a high-pressure reactor 4, a throttle valve 5, a low-pressure reactor 6, a cyclone separator 8, a condenser 9, and a liquid-liquid separator 10. Composed of water pump 12, cooling tower 13, condensing pressure control valve 14, and return flow control valve 15. The high-pressure reactor 4 is in the shape of a thin tube with a diameter of 3-10 mm. The low-pressure reactor 6 adopts slender straight pipes or coiled pipes with a pipe diameter of 10-20mm. The mud container 1 is connected to the mud pump 2 through the pipeline, and the high-pressure reactor 4 is connected through the flow control valve 3 , and its outlet is connected with the low-pressure reactor 6 through the throttle valve 5 . The outlet of the low-pressure react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com