Horizontal rotary multi-disc atomization device

An atomization device and multi-disc technology, which is applied in the direction of muffler, exhaust device, exhaust treatment, etc., can solve the problems of failure and difficult clogging of the rotating packing bed, achieve enhanced gas-liquid mixing ability, and occupy a small space , Easy to install, disassemble and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings of the specification.

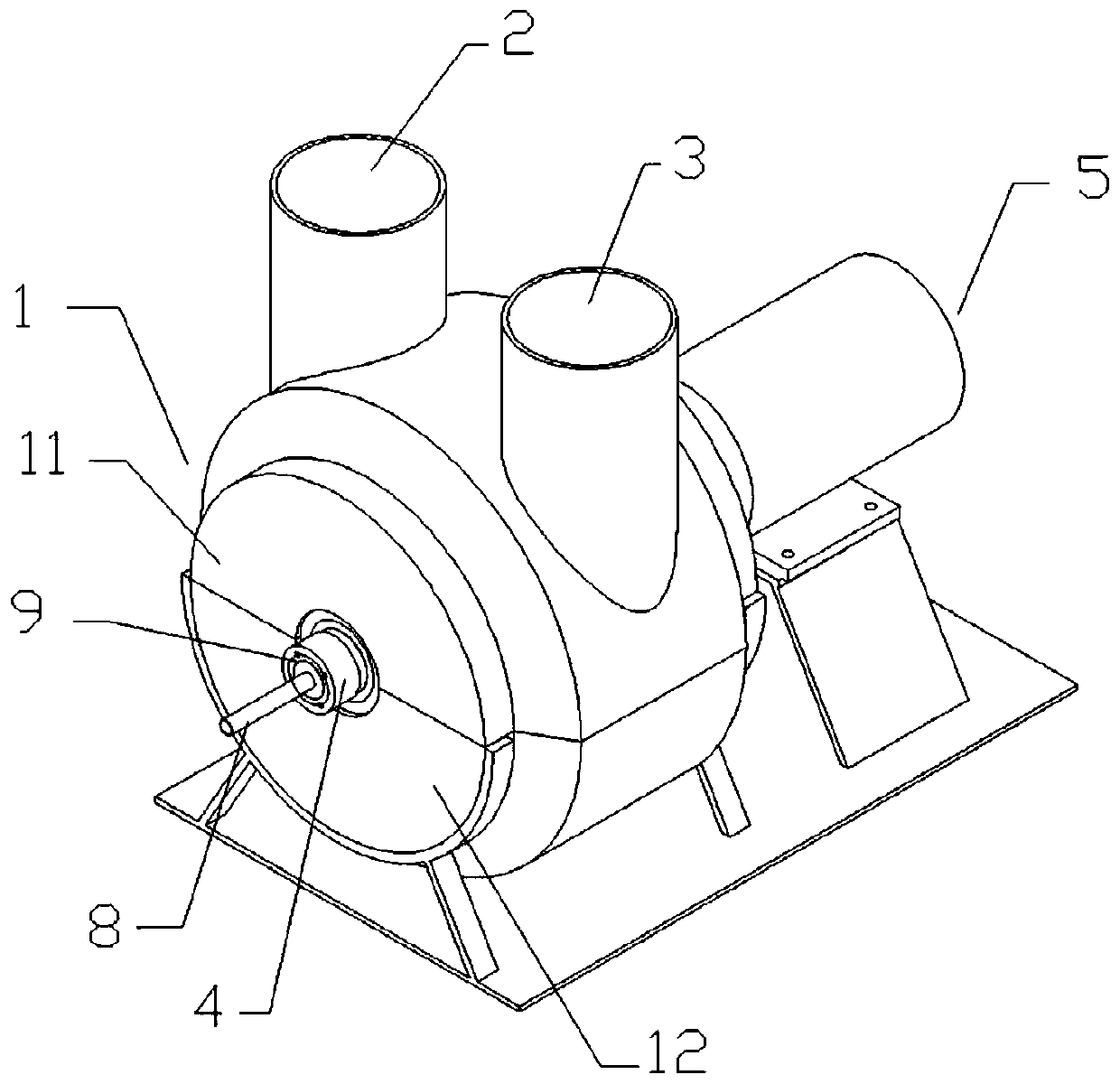

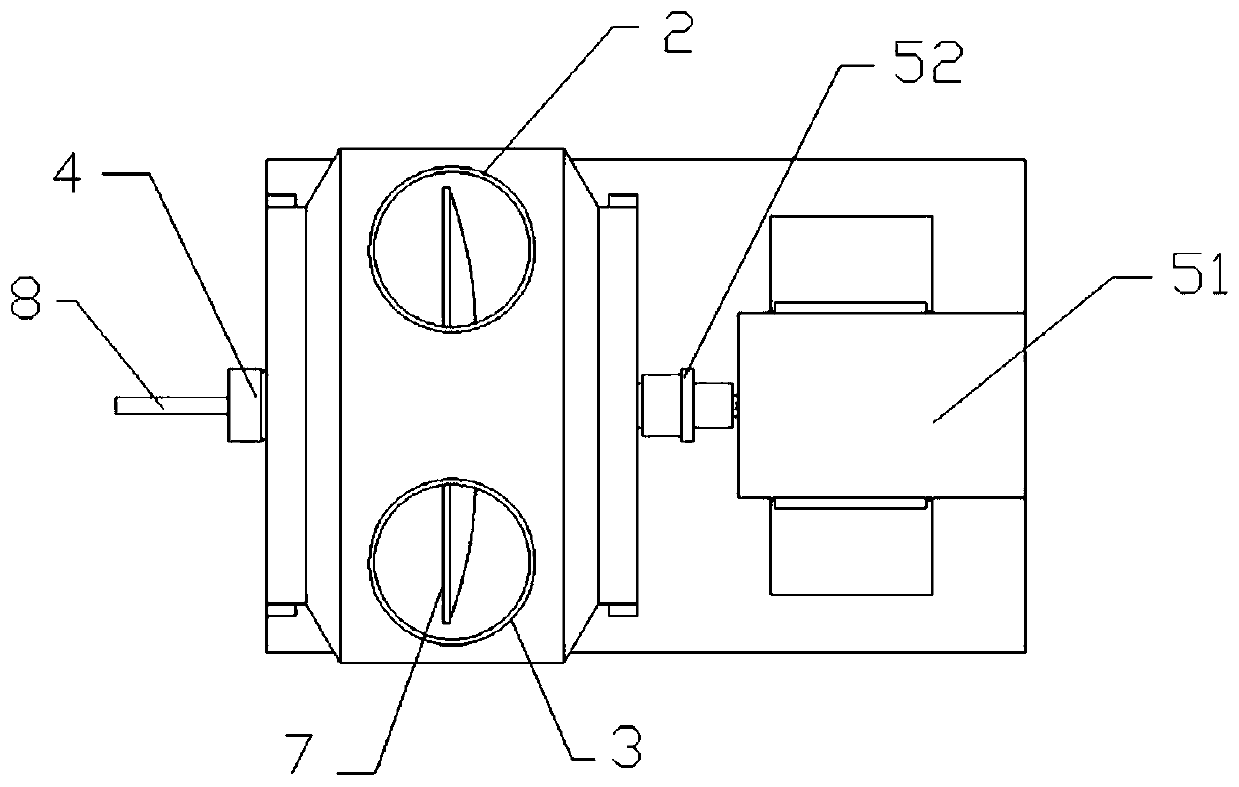

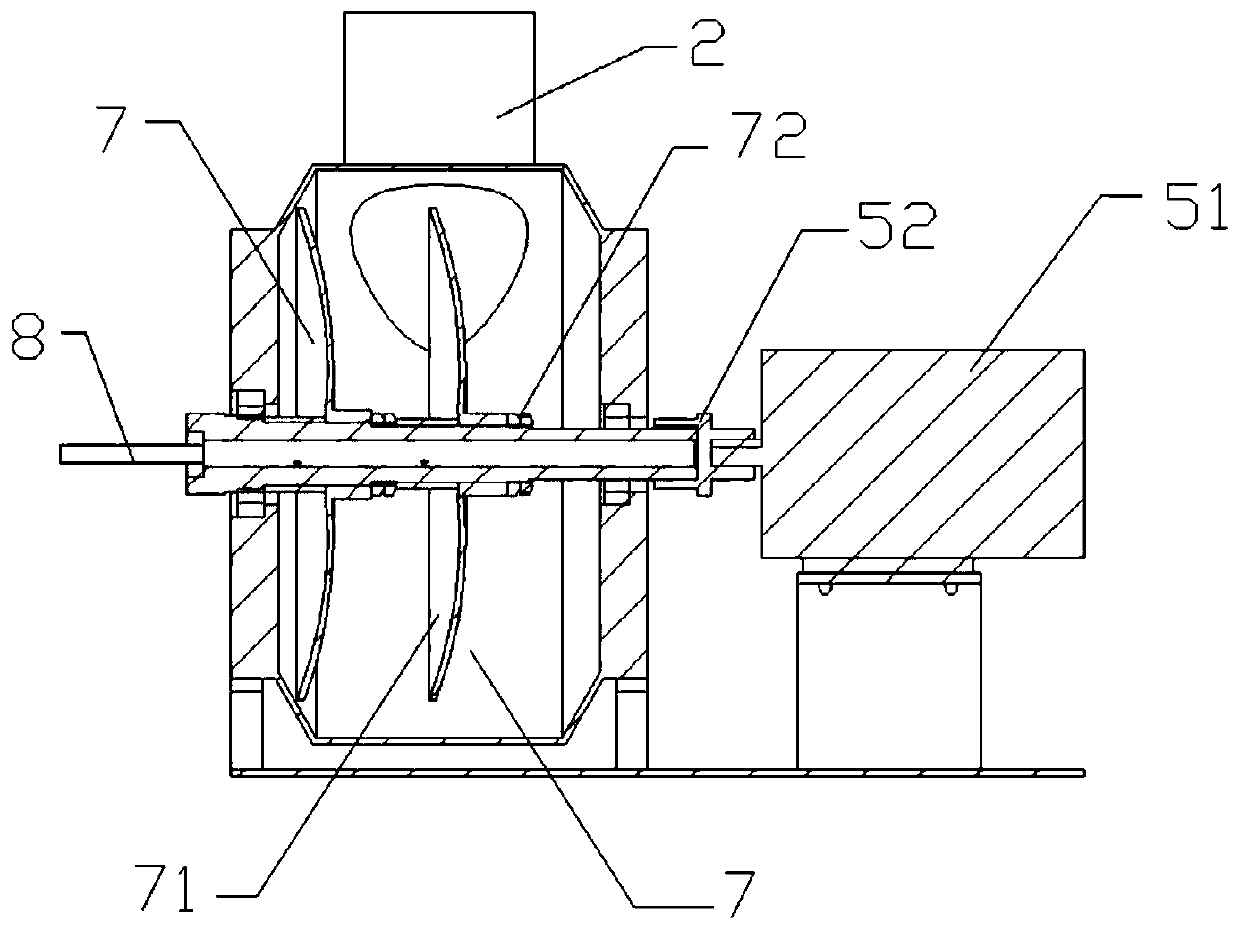

[0025] Such as Figure 1~7 As shown in the figure, the horizontal rotary multi-disk atomization device includes a cylinder body 1, an air inlet 2, an air outlet 3, a rotating shaft 4, a power unit 5 and a liquid discharge port 6. The cylinder body 1 is provided with an air inlet 2 and the exhaust port 3, the lower end of the cylinder 1 is provided with a drain port 6, and both the absorption liquid and the waste liquid after the reaction can be discharged through the drain port 6.

[0026] The power unit 5 is connected with the rotating shaft 4, and the ends of the power unit 5 and the rotating shaft 4 can be connected either flexibly or rigidly; the rotating shaft 4 is a hollow rotating shaft, and the hollow part of the rotating shaft 4 can smoothly pass the absorbing liquid. The rotating shaft 4 is installed inside the cylinder 1 , The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com