Thin oil lubrication sealing device for vacuum roller liner bearing

A thin oil lubrication and sealing device technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of shortened life, increased transmission power loss, and loss of paper mill users, so as to prolong the service life and bearing life increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

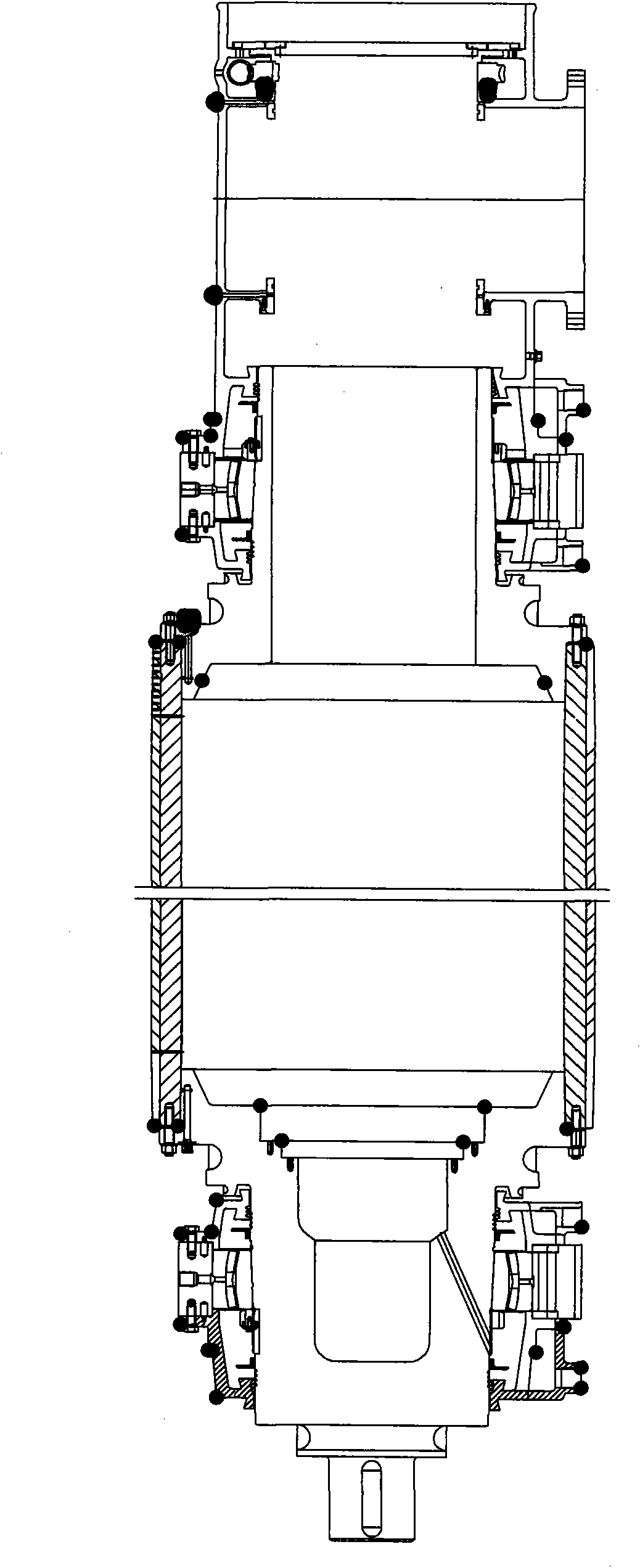

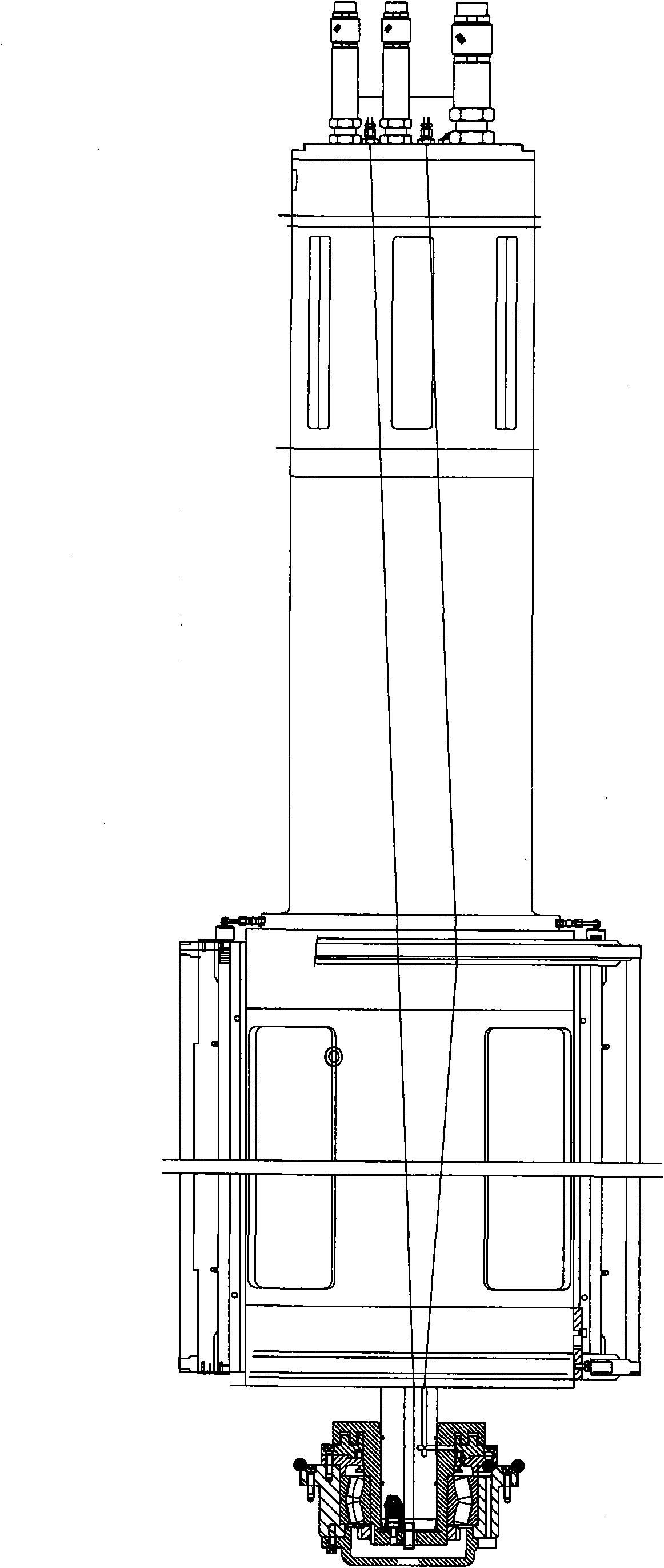

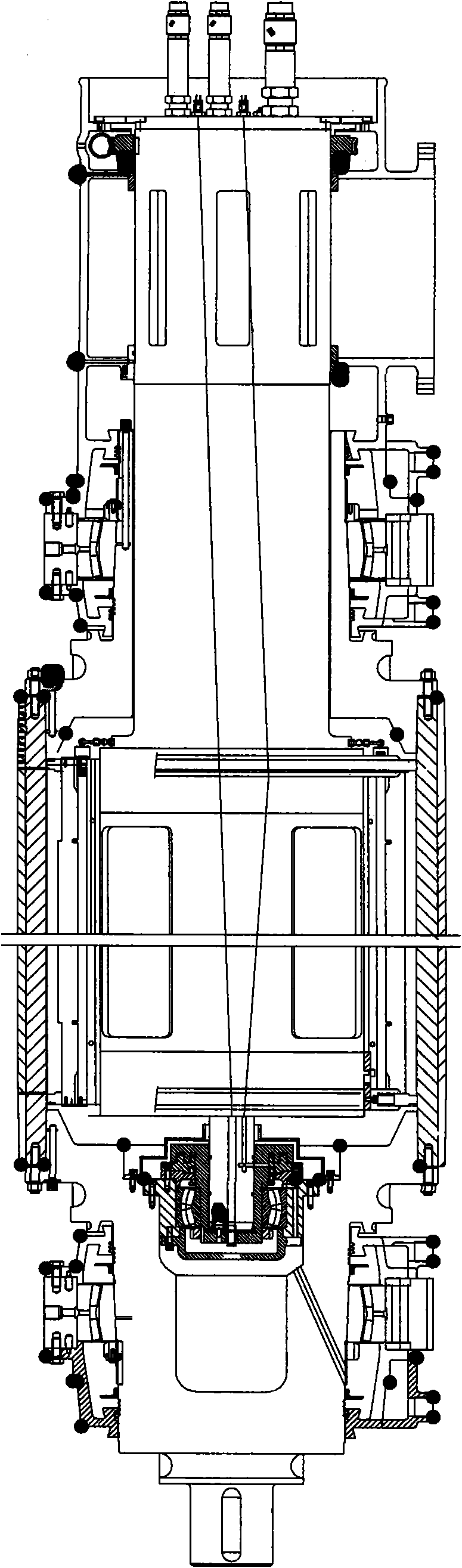

[0026] Embodiment: A vacuum roller liner bearing thin oil lubrication and sealing device, the bearing is set between the inner liner and the shaft head of the transmission side, the bearing seat 1 is fixed on the shaft head of the transmission side, and the bearing 10 is fixedly sleeved on the shaft sleeve 3 Above, the shaft sleeve 3 is fastened to the inner tank shaft 4 through the lock nut 8, the bearing 10 is arranged in the bearing seat 1, the bearing cover 5 is fixed on one end surface of the bearing seat 1, and the bearing cover 5 can just close the inner tank shaft 4 At one end, one end surface of the inner bearing cover 6 is fixed to the other end surface of the bearing housing 1 .

[0027] There is a gap 13 and a flaring chamber 14 between the shaft sleeve 3 and the inner bearing cover 6. The gap 13 communicates with the flaring chamber 14. The flaring chamber 14 is farther away from the bearing 10 than the gap 13, so that the thin oil coming out of the gap 13 can be e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com