Direct-cooling deep-enthalpy heat-extracting coal mine gas heat pump system

An air-heat pump and cold-type technology, which is applied in the system field of recovering exhausted air and waste heat in coal mines, can solve the problems of not being too far away, the height difference is not too large, and the utilization rate of return air is low, so as to reduce the number of pipelines and make the relative positions flexible , the effect of small water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

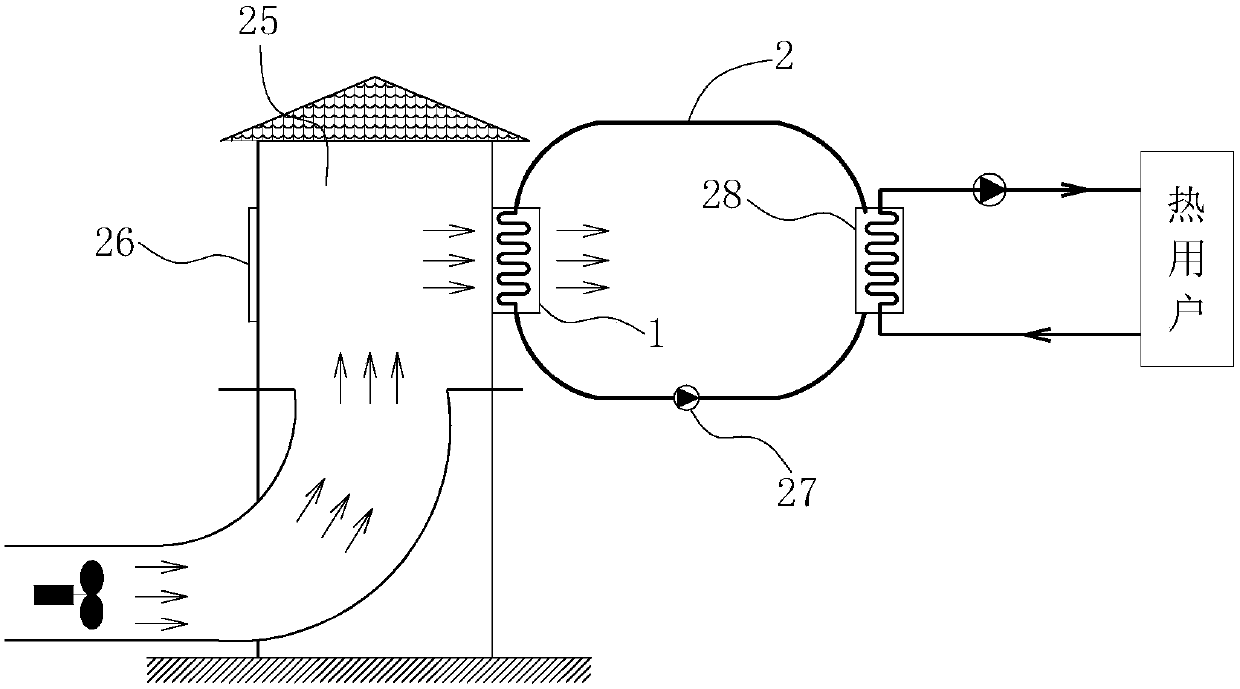

[0031] like image 3 As shown, the direct-cooling deep enthalpy exhaust air heat pump system of the present invention includes a exhaust air heat extraction chamber 25, and at least one exhaust air heat extraction box 1 is arranged on the exhaust air heat extraction chamber 25. The hot box 1 communicates with the evaporator of the heat pump unit 28 through the antifreeze pipeline 2, the antifreeze pipeline 2 is used to flow through the antifreeze, the circulation pump 27 is installed on the antifreeze pipeline 2, and the antifreeze When flowing through the exhaust air heating box 1, the heat in the exhaust air is absorbed, and when the antifreeze flows through the evaporator, the heat in the absorbed exhaust air is converted to the refrigerant in the heat pump unit 28, and the heat pump unit 28 The condenser in the unit is used to exchange heat with the user's hot water.

[0032] The exhaust air heat extraction chamber 25 is set at the mouth of the coal mine return air diffus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com