Precoated sand casting method for large castings

A large-scale casting and coated sand technology, which is applied in the field of large-scale casting, can solve the problems of large-scale casting, personnel injury, and low efficiency of manual sand removal, and achieve the effect of improving casting efficiency and reducing cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

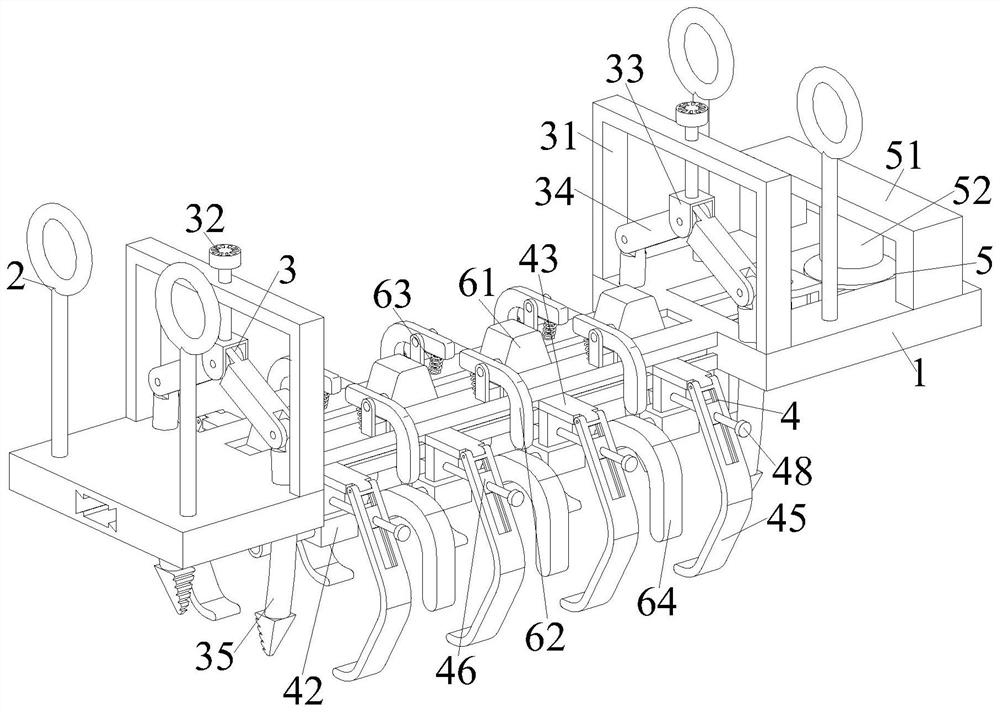

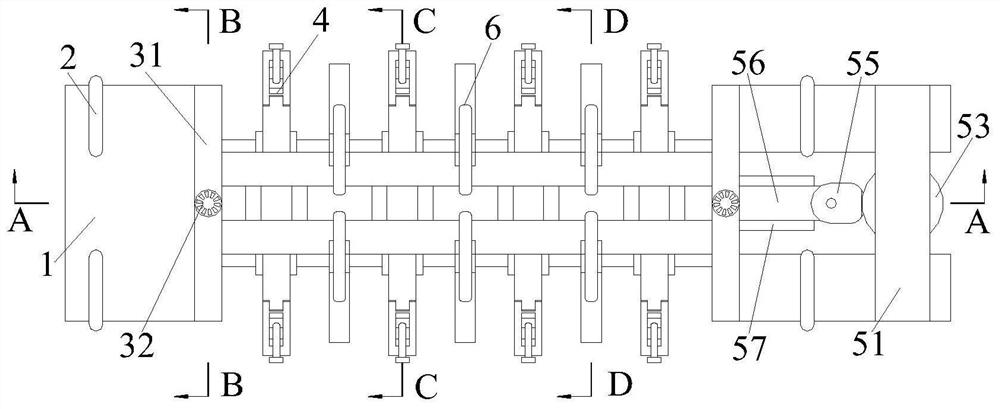

[0038] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

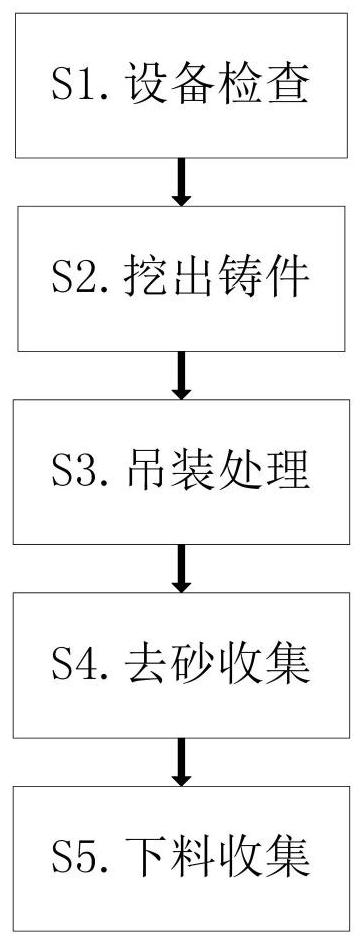

[0039] A method for casting coated sand for large castings, the specific casting method is as follows:

[0040] S1. Equipment inspection: check the equipment before using the large casting coated sand casting equipment to hoist the large casting after casting;

[0041] S2. Digging out castings: after the equipment inspection is completed, the hoisting plate 1 is brought close to the sand mold, so that the digging device 3 digs out the large castings from the sand, and after the castings are dug out, they are hoisted out of the sand mold;

[0042] S3. Hoisting treatment: after the casting is dug out, the position of the clamping device 4 is manually adjusted so that the clamping device 4 clamps and fixes the excavated casting, and after the casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com