Rainwater pipeline rotational flow grit chamber

A technology of swirling grit chamber and grit chamber, which is applied in the direction of separating sediments by centrifugal force, feeding/discharging device of settling tank, etc., can solve problems such as inconvenient operation and management, and achieve convenient operation and management, simple structure, The effect of high sand removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

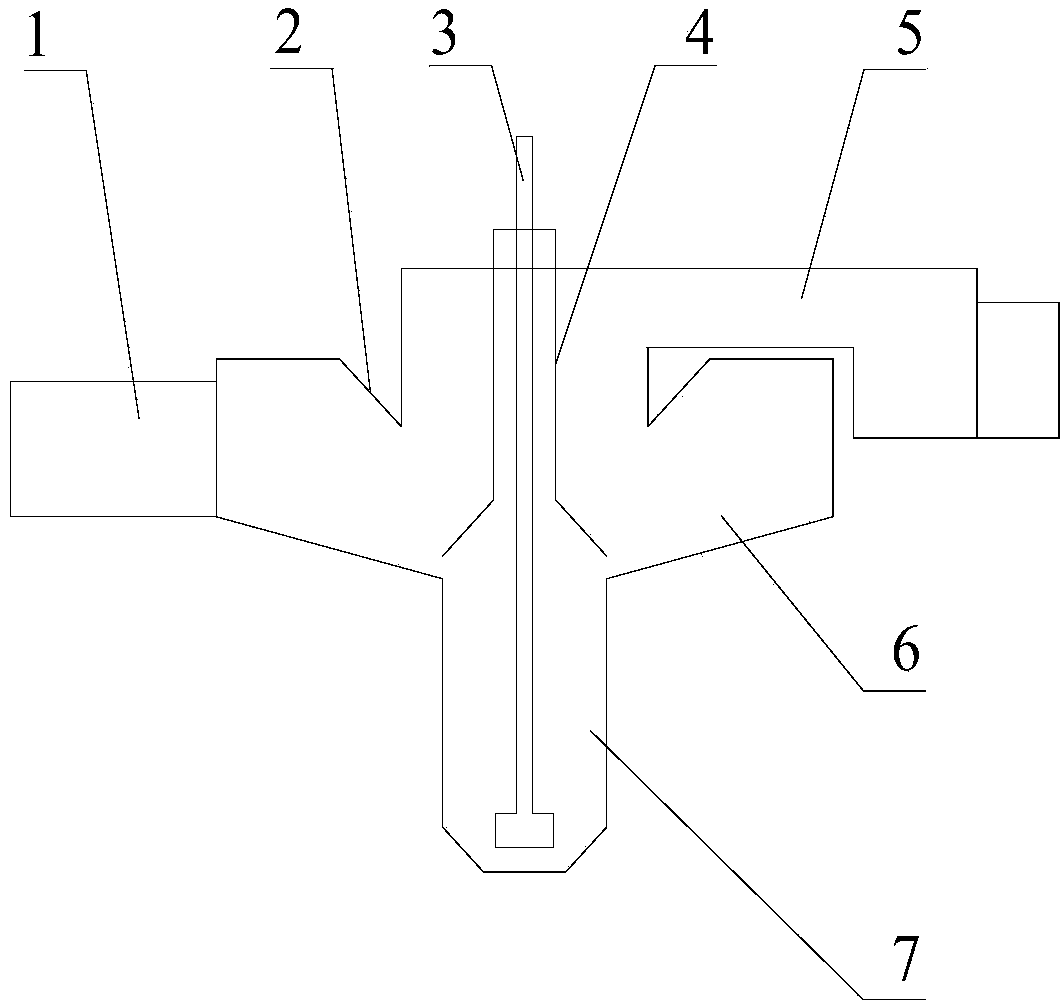

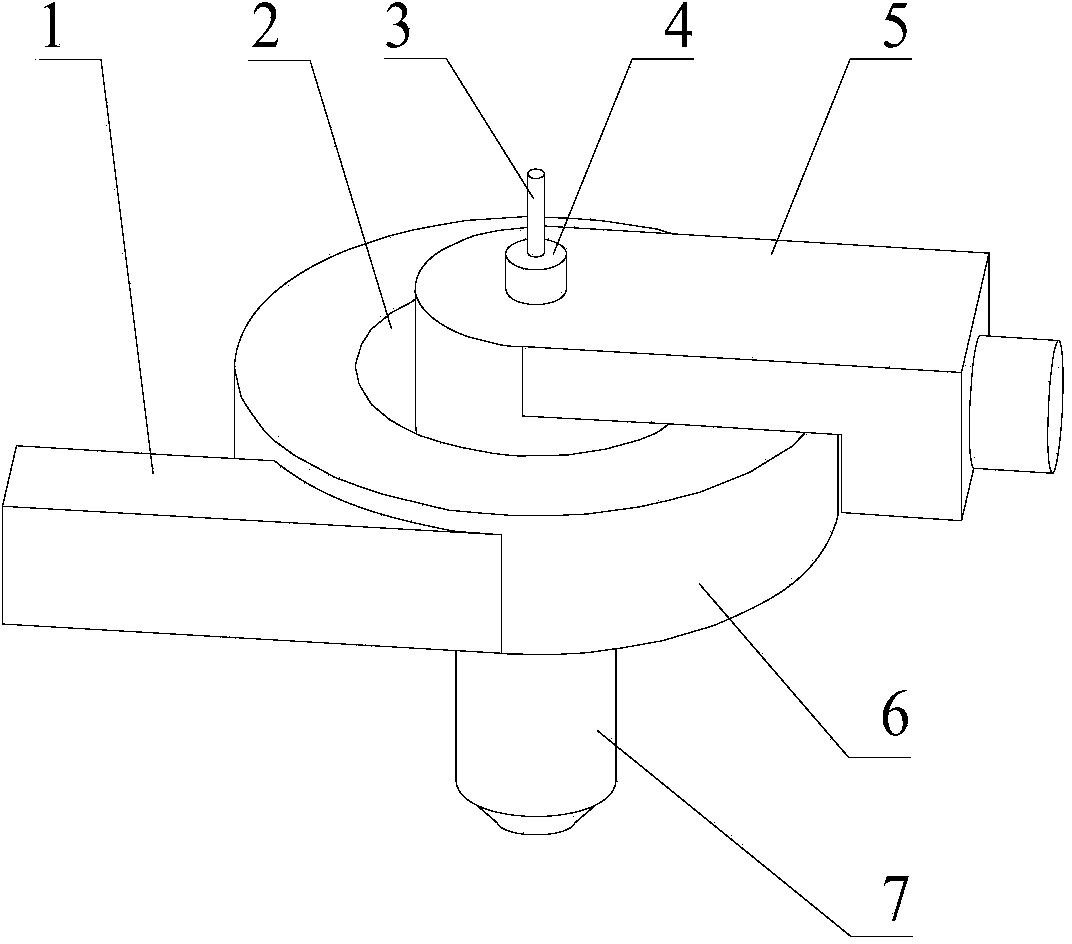

[0014] Such as figure 1 and figure 2 As shown, a rainwater pipe swirling grit chamber includes a grit chamber 6, an inlet pipe 1, an outlet pipe 5 and a sand collecting bucket 7 at the bottom of the grit chamber. The beginning of the water inlet pipe 1 is connected to the upstream municipal rainwater pipe through a flange, and the direction of the water inlet pipe 1 is tangent to the side wall of the grit chamber 6. Rain pipe diameter. The diameter of the grit chamber 6 is equal to 5 times the side length of the cross section of the water inlet pipe 1, and the bottom surface of the grit chamber 6 is inclined, and the slope of the bottom surface is 1:4. The top of the grit chamber 6 is provided with a rounded table-shaped deflector 2, the central axis of the deflector 2 coincides with the central axis of the grit chamber 6, and the upper edge of the deflector 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com