Sewage sand-filtering equipment

A sewage and sand filtering technology, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of increased time and cost of sewage treatment, and achieve improved mixing efficiency, convenient mixing, and improved removal The effect of sand efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

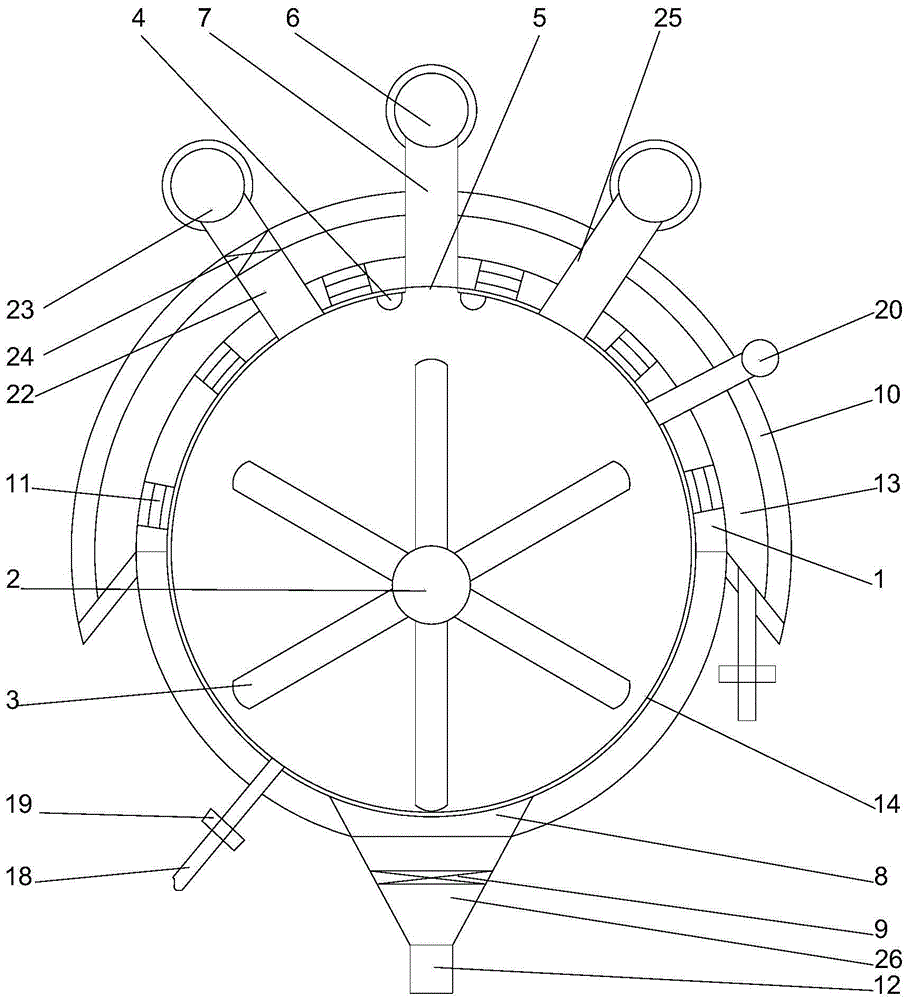

[0022] like figure 1 As shown in / 2, a sewage sand filter equipment includes a hollow cylindrical filter barrel 1 and a rotating shaft 2 arranged inside the filter barrel, and a water accumulation plate 10 is arranged on the filter barrel. The water accumulation plate has a semi-circular structure, and the water accumulation plate is set on the upper part of the filter barrel, and a water accumulation cavity 13 is formed between the water accumulation plate and the upper outer wall of the filter barrel, and the A through hole is provided on the end surface of the filter barrel facing the water accumulation plate, and the through hole communicates with the inner side of the filter barrel and the water accumulation chamber, and a filter screen is arranged inside the through hole 11. A drain valve is provided on the water accumulation plate, the axis of the rotating shaft and the axis of the filter bucket are staggered from each other, the axis of the rotating shaft is located be...

Embodiment 2

[0025] In this embodiment, on the basis of Embodiment 1, in order to conveniently control the pressure in the filter barrel, in this embodiment, preferably, a pressure relief valve 20 is provided on the filter barrel.

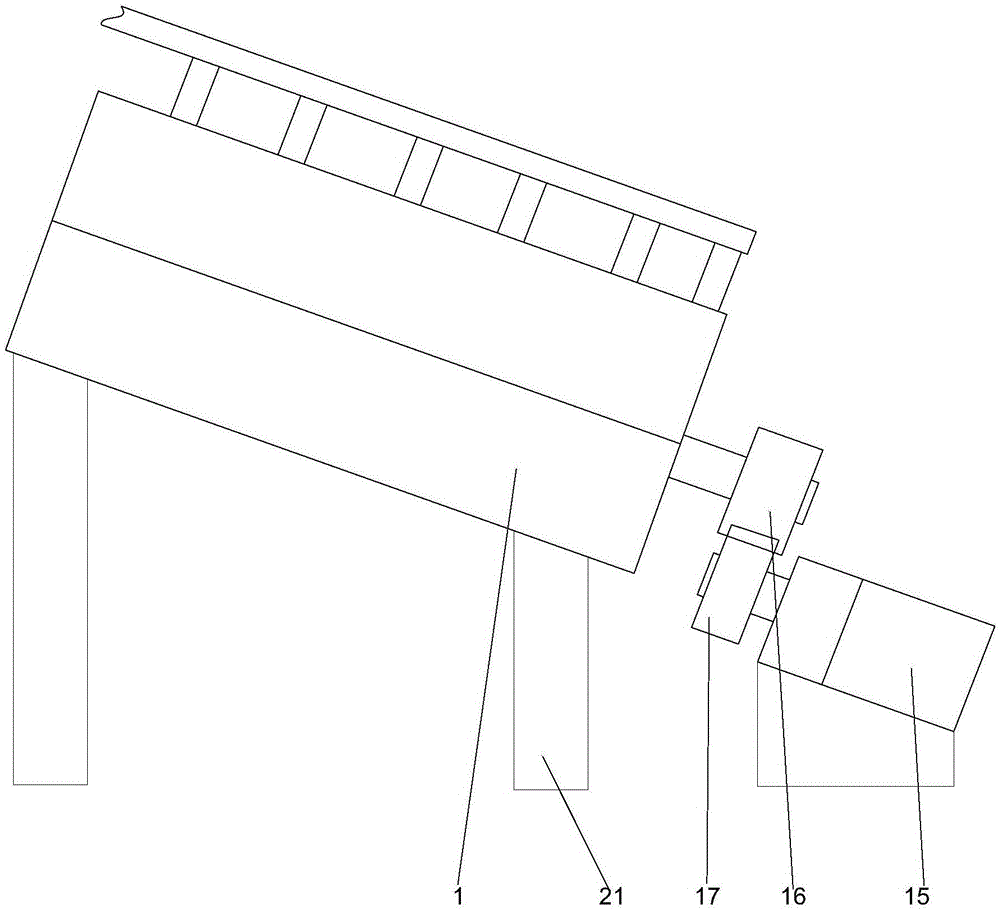

[0026] In order to facilitate the support of the filter bucket, in this embodiment, preferably, brackets 21 are provided respectively under the two ends of the filter bucket, and the heights of the upper ends of the two brackets are not equal. By making the heights of the two brackets unequal, the heights of the two ends of the filter barrel can be made different, so that the materials can move relatively under the action of gravity, thereby improving their mixing efficiency.

[0027] In this embodiment, when the sewage contains heavy metal ions, in order to facilitate the discharge of impurities in the sewage more fully, preferably, a dosing valve 25 is arranged on the filter barrel, and on the dosing valve A metering pump is provided. Meter the amount of flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com