Trailer type sand elimination machine for railway

A technology for railways and trailers, applied in cleaning methods, track cleaning, construction, etc., can solve the problems of difficult maintenance of sand blowing steering mechanism, high cost, large vehicle volume, etc., and achieves easy promotion, simple operation, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

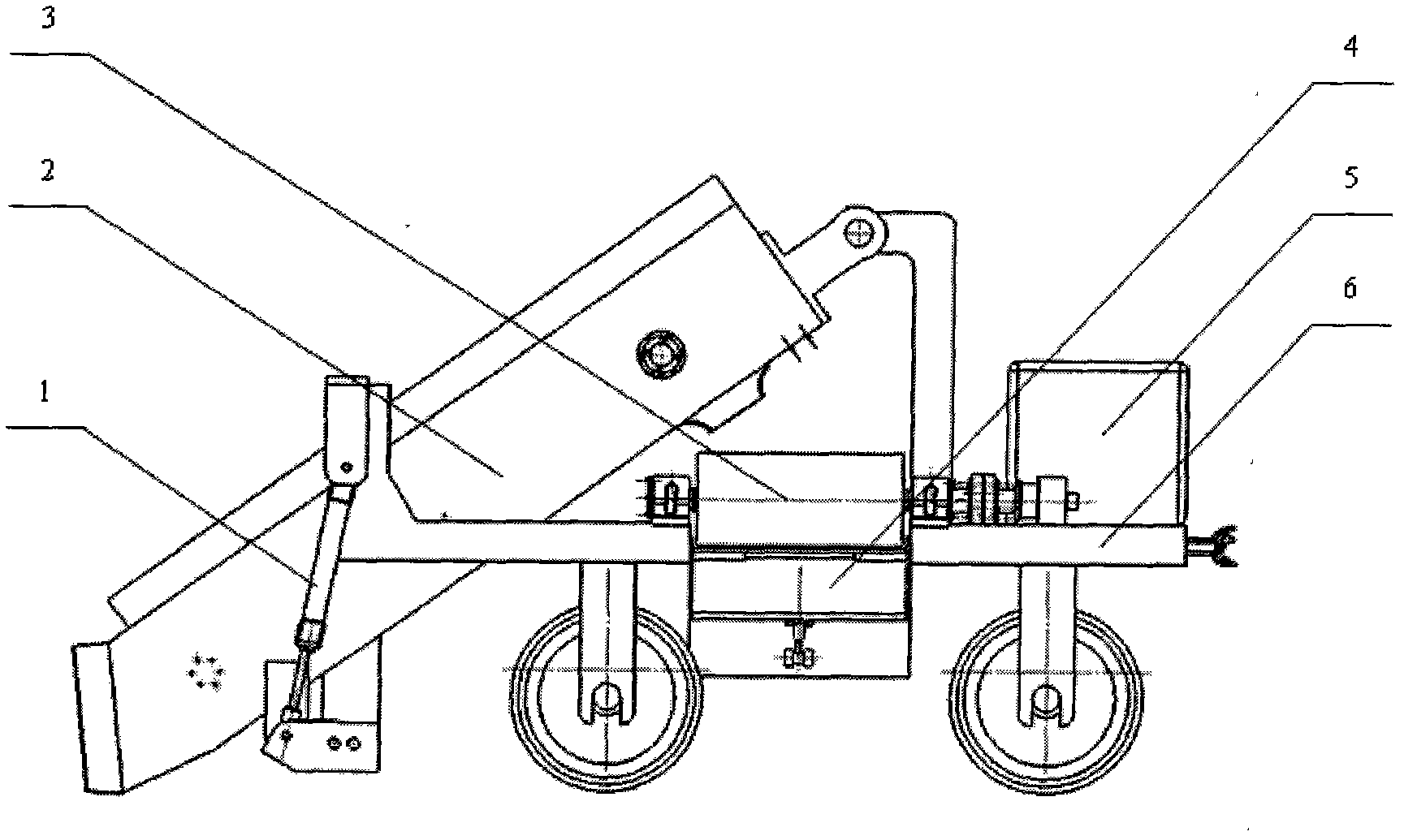

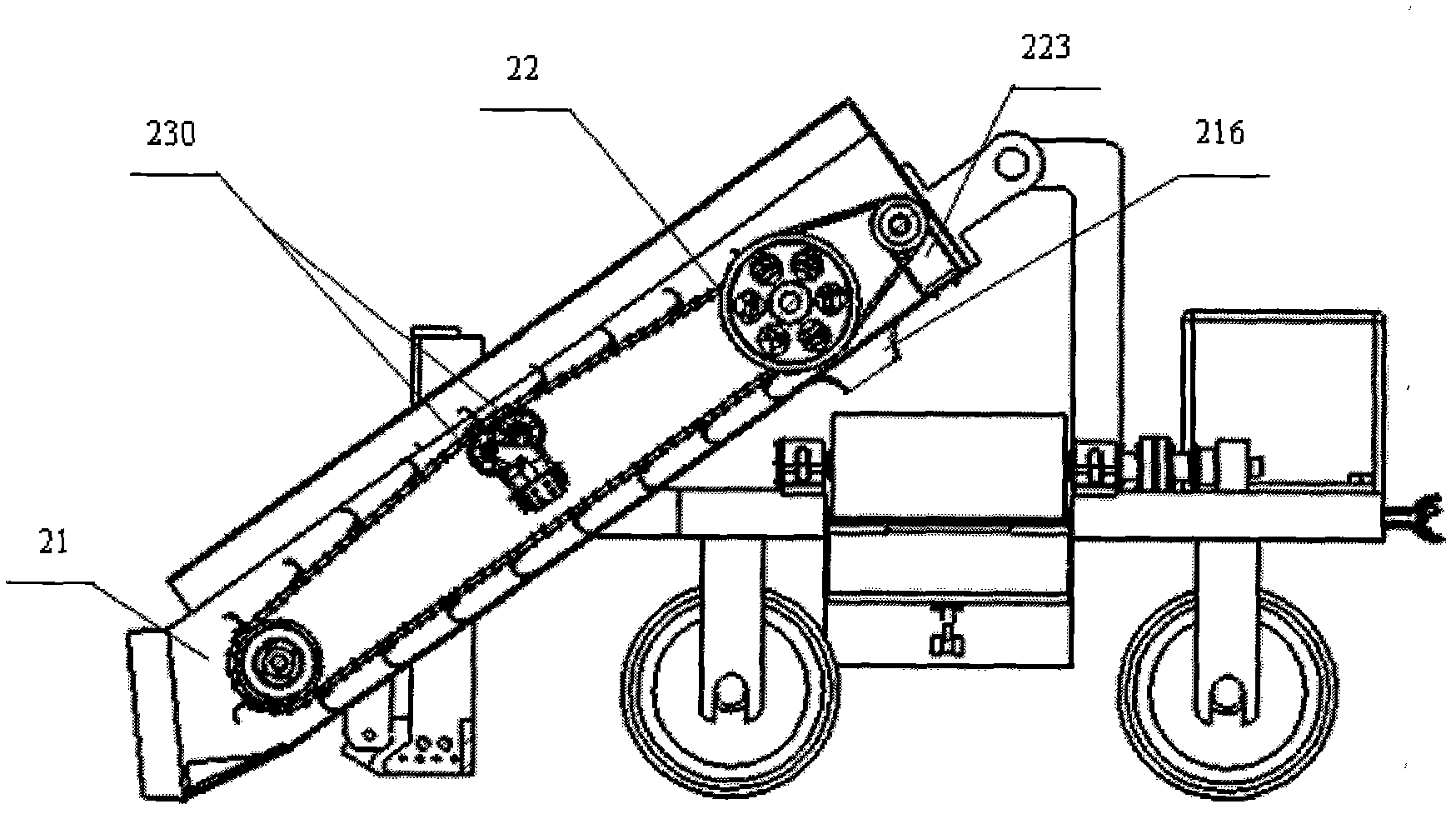

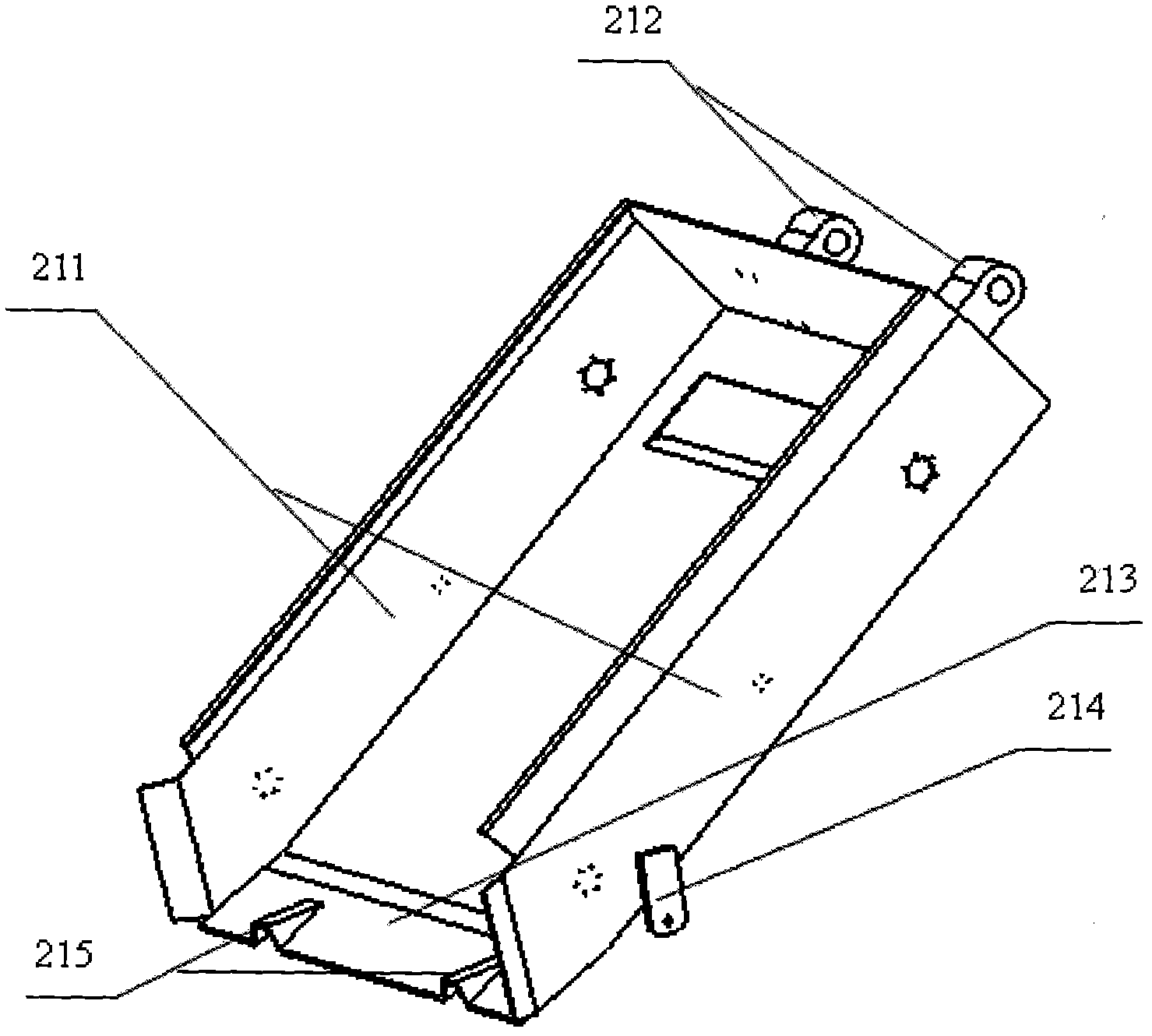

[0019] Refer to attached Figure 1-10 , The main structure of the trailer-type railway sand removal machine of the present invention includes a lifting hydraulic cylinder 1, a sand collection and scraping device 2, a two-way sand blowing mechanism 3, a sand blowing conveying mechanism 4, a hydraulic system 5 and a car body 6. Wheel 65 on the car body 6 and axle 66 select the model that matches with railroad track for use, guarantee the safety on the road; , driven by the locomotive to the work site, after the work is over, it can be disengaged without affecting the normal work of the locomotive, and there is no need to equip a special locomotive. The front sand collection and scraping device 2 is hinged with the connection structure 63 between the sand collection box and the car body through the connection structure 212 on the sand collection box and the sand collection box, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com