Device and method for desanding of submarine natural gas hydrate exploitation well

A natural gas and hydrate technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., to reduce equipment wear and improve sand removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

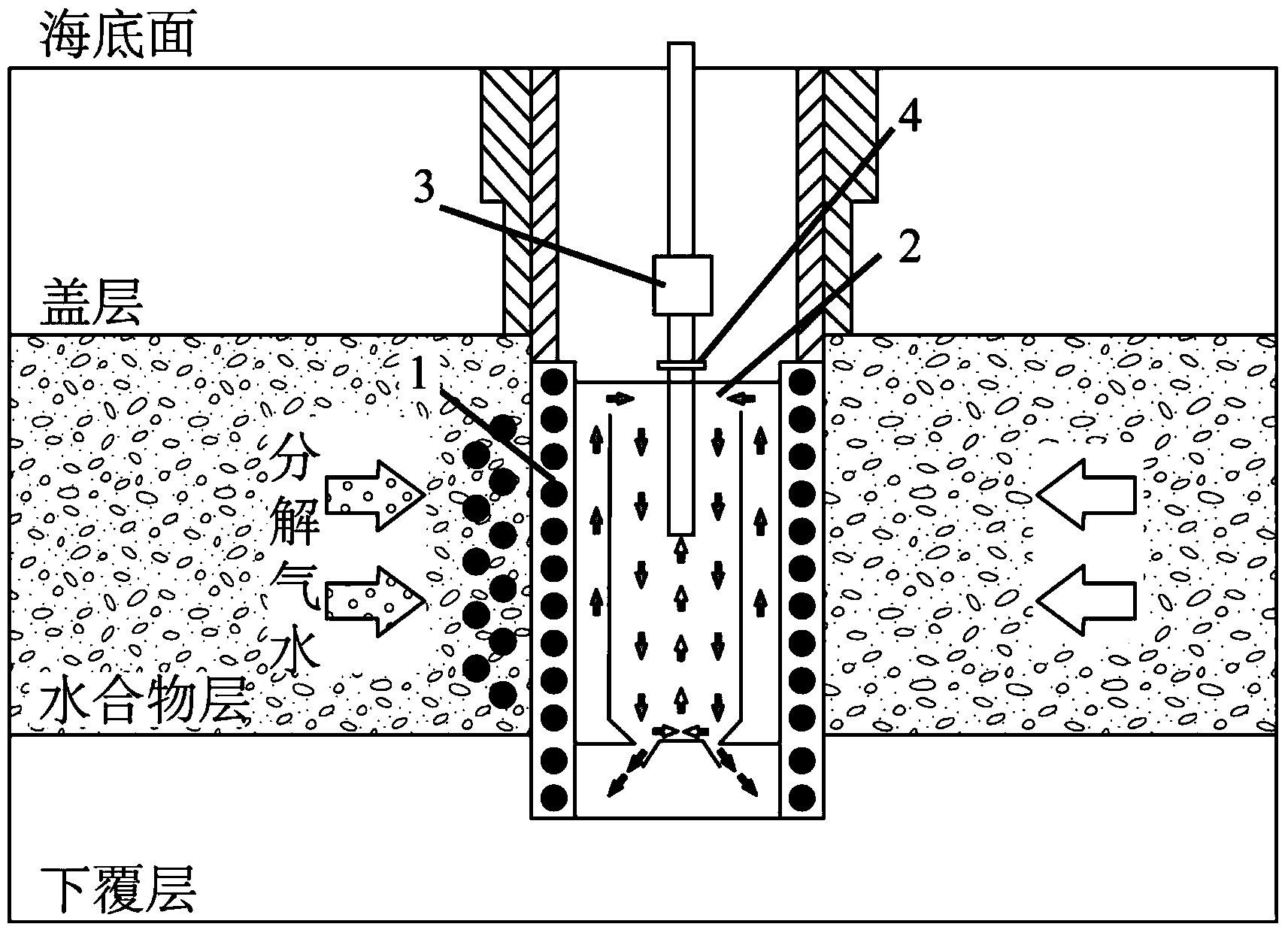

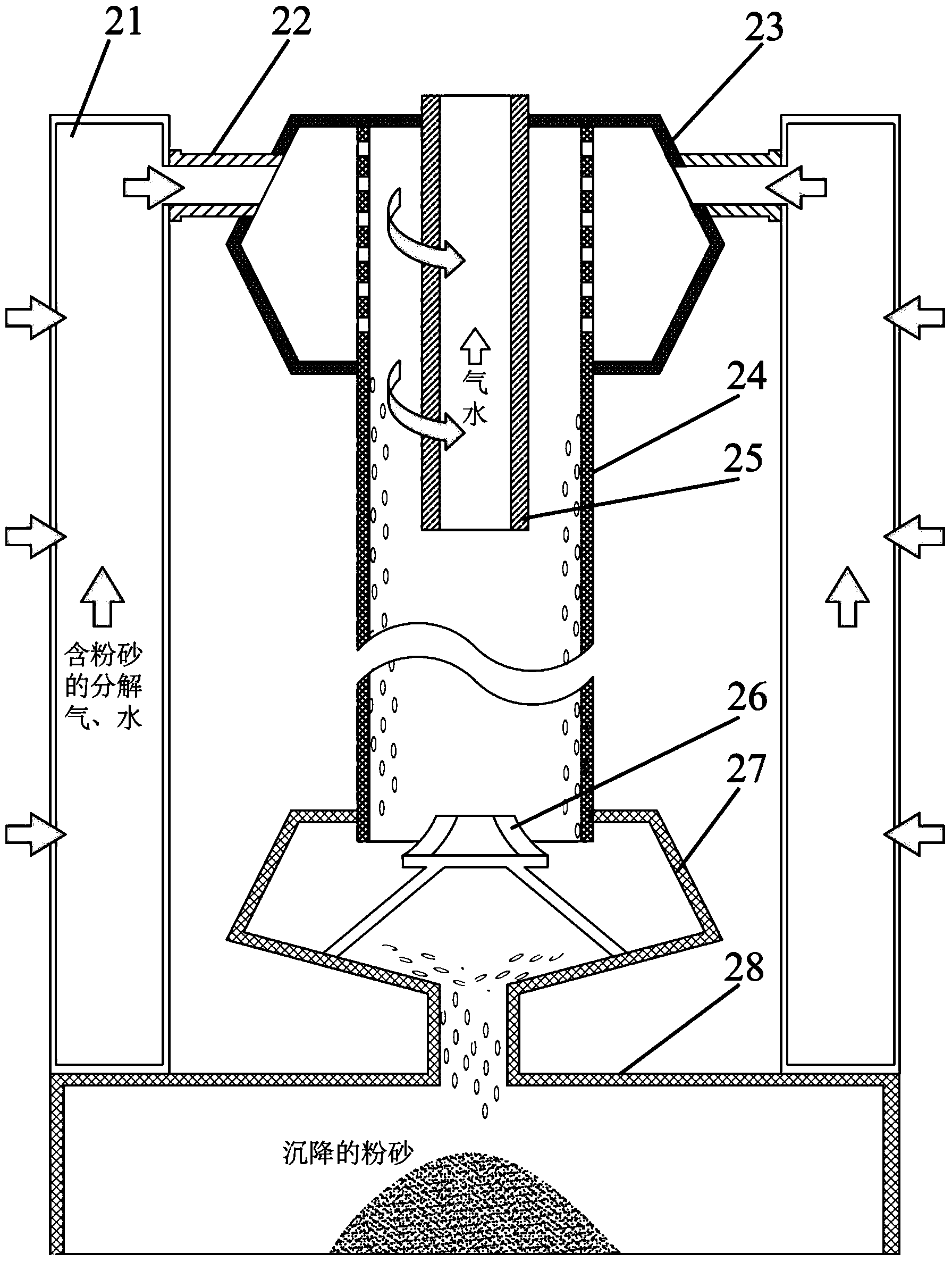

[0023] Combine below figure 1 , figure 2 The present invention is described in detail with examples.

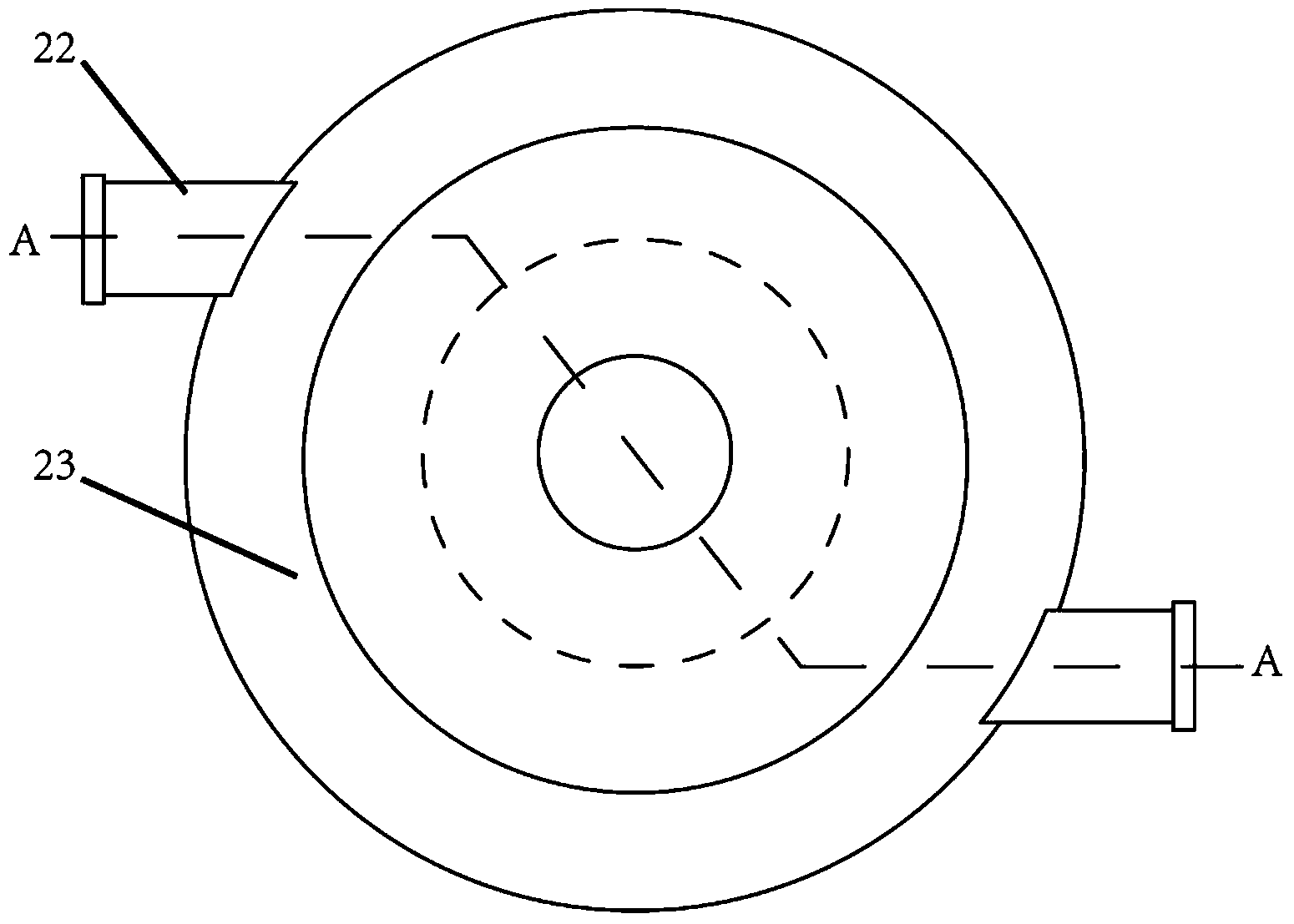

[0024] 1. After the drilling is completed, the gravel packing group 1 is first lowered to the bottom of the wellbore, and then the centrifugal desander 2 and the submersible pump 3 are connected with the connecting flange 4 and lowered to the bottom of the wellbore as a whole, such as figure 1 As shown, at this time, the outer wall of the diversion chamber 21 of the centrifugal desander is attached to the inner wall of the gravel packing group 1;

[0025] 2. After the mining starts, the gas, water and mobile sand produced by the decomposition of the natural gas hydrate layer flow to the wellbore. The larger sediment particles are blocked by the gravel packing group 1, and the smaller particles of silt enter the centrifugal removal along with the decomposed gas and water. sander 2;

[0026] 3. The decomposed gas and water containing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com