Rail ballast bed sand removal vehicle

A technology for removing sand trucks and ballast beds, applied in track cleaning, construction, cleaning methods, etc., can solve problems such as the inability to ensure the normal operation of sand removal trucks, setting up sand removal plows, and secondary pollution, so as to reduce erosion by sand and soil, Ease of maintenance and prolong working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

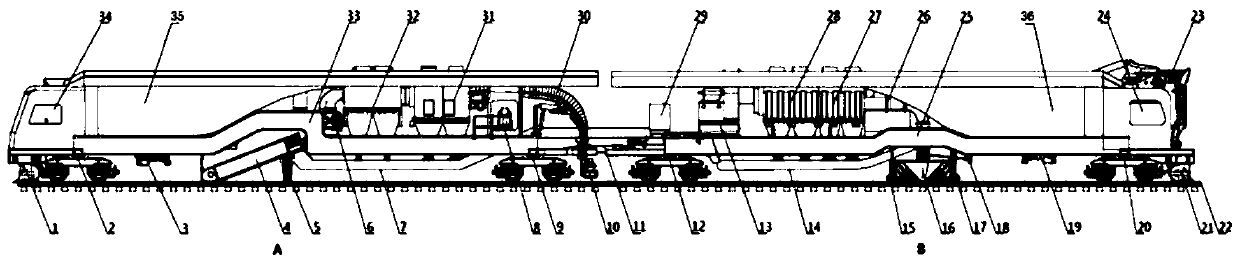

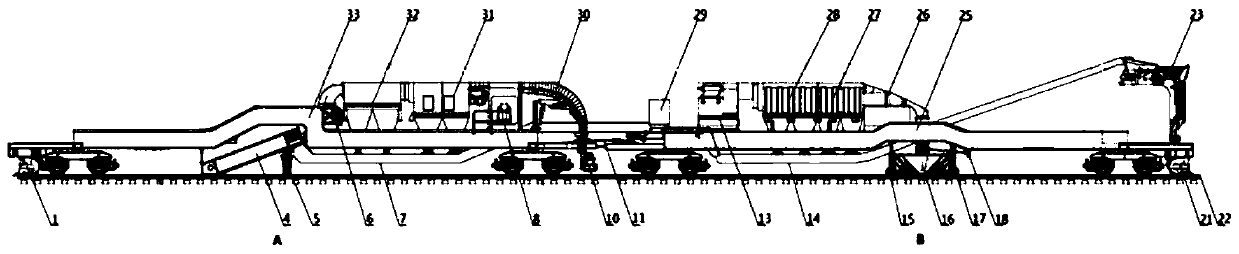

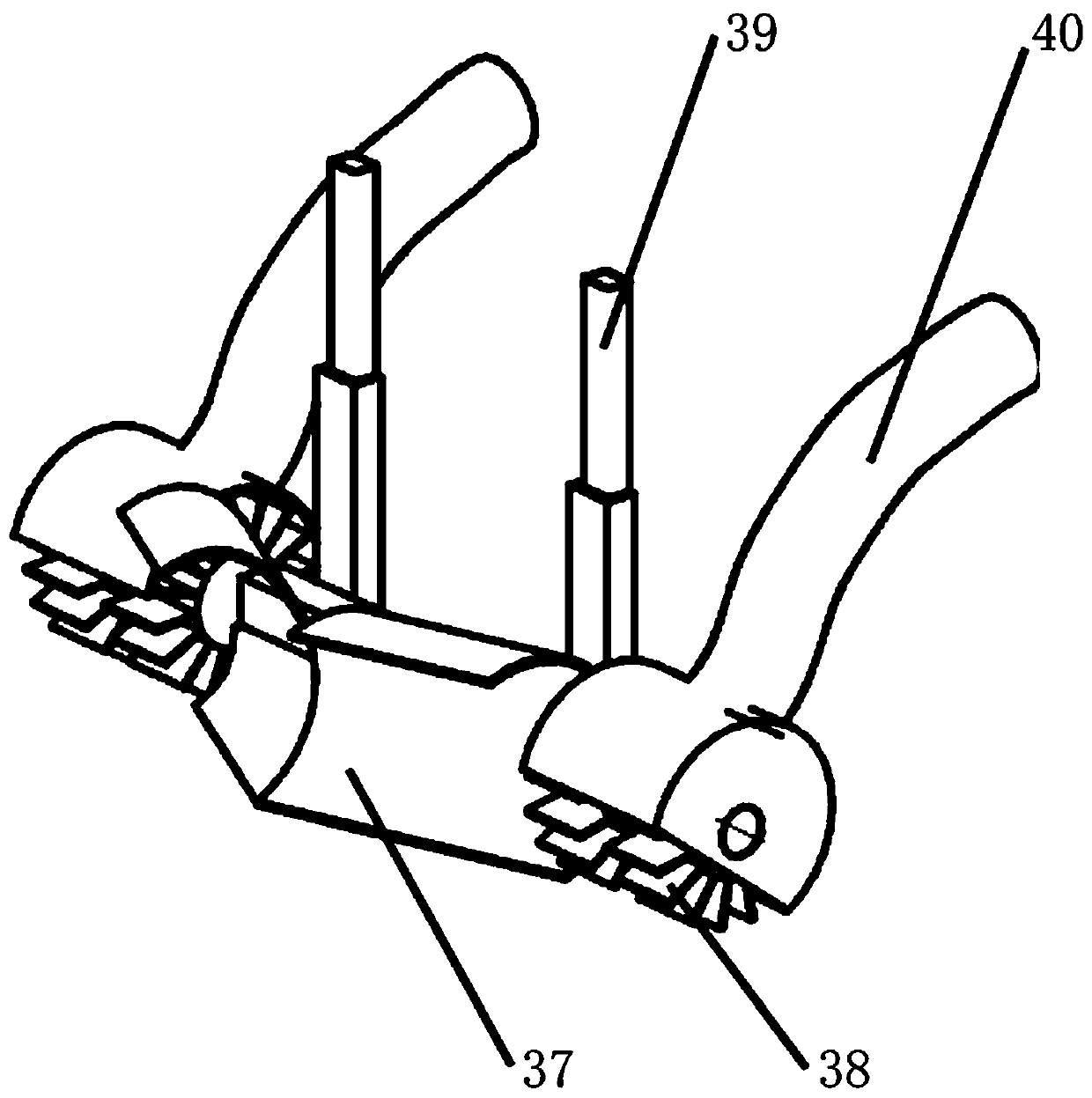

[0034] Combine below Figure 1-8 Describe in detail the technical scheme of the track bed desanding vehicle:

[0035] The present invention sets: the direction that track 22 extends parallel to the steel rail is longitudinal, and the direction that track 22 extends perpendicular to the steel rail is horizontal; The direction of the driver's cab 24 .

[0036] The track bed desanding vehicle includes a vehicle A and a vehicle B, and the vehicle A is connected to the vehicle B through a connecting beam 11. The vehicle A includes a main frame 33 of the vehicle A, a front bogie 2 of the vehicle A, and a vehicle A Car rear bogie 9, A car owner's frame 33 front lower part, rear lower part are equipped with A car front bogie 2, A car rear bogie 9 respectively, and the front upper part of A car owner's frame 33 is equipped with A car driver's cab 34, In the middle part of A car main vehicle frame 33, mechanical desanding device is fixedly installed, and front row sand plow 1 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com