Rice primary cleaning method

A preliminary technology for rice, applied in the field of rice production equipment, can solve the problems of reducing the cleaning efficiency of magnet iron materials, increasing the production process of rice, increasing costs, etc., to achieve the effect of improving dust removal effect, improving screening efficiency, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

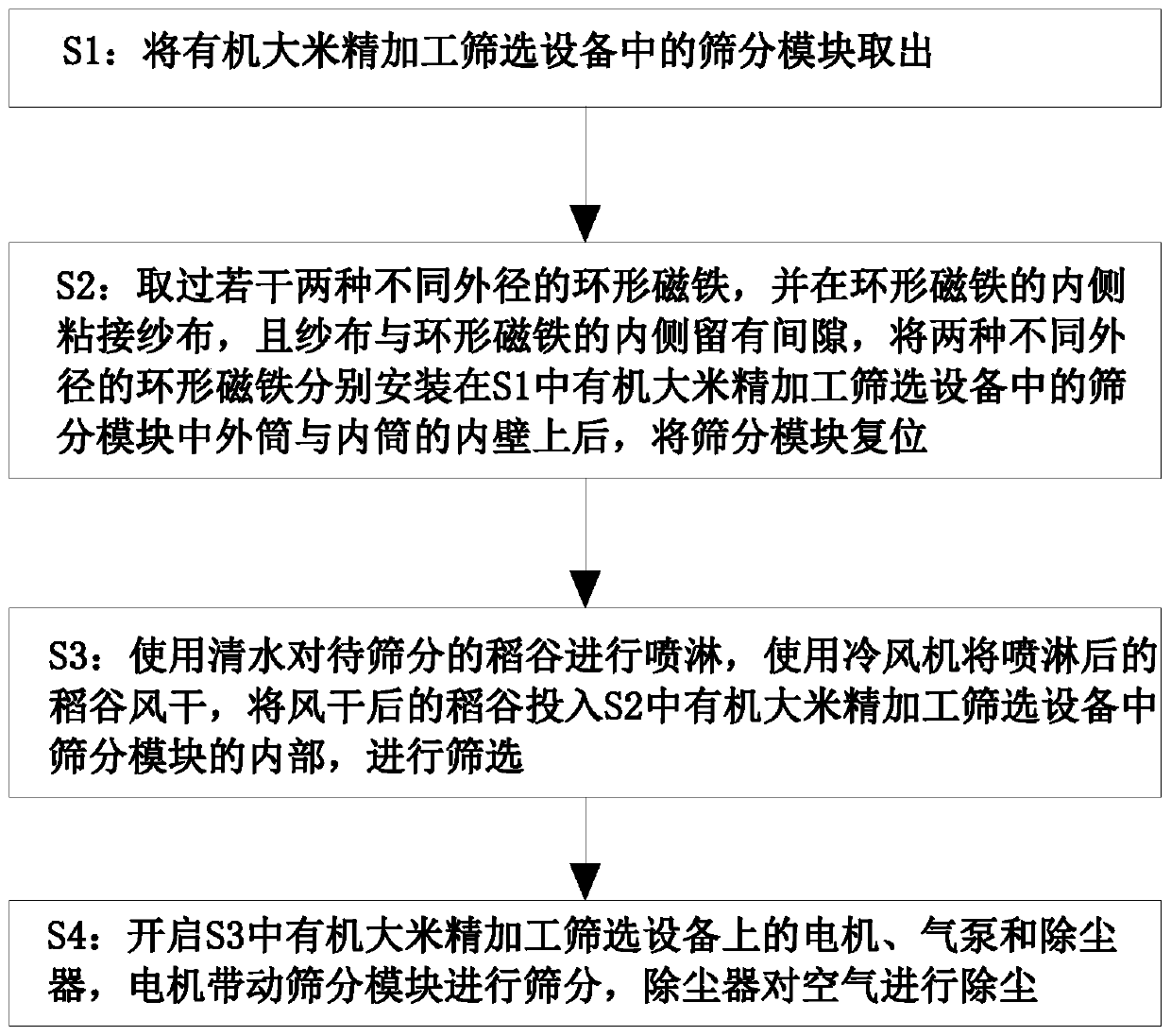

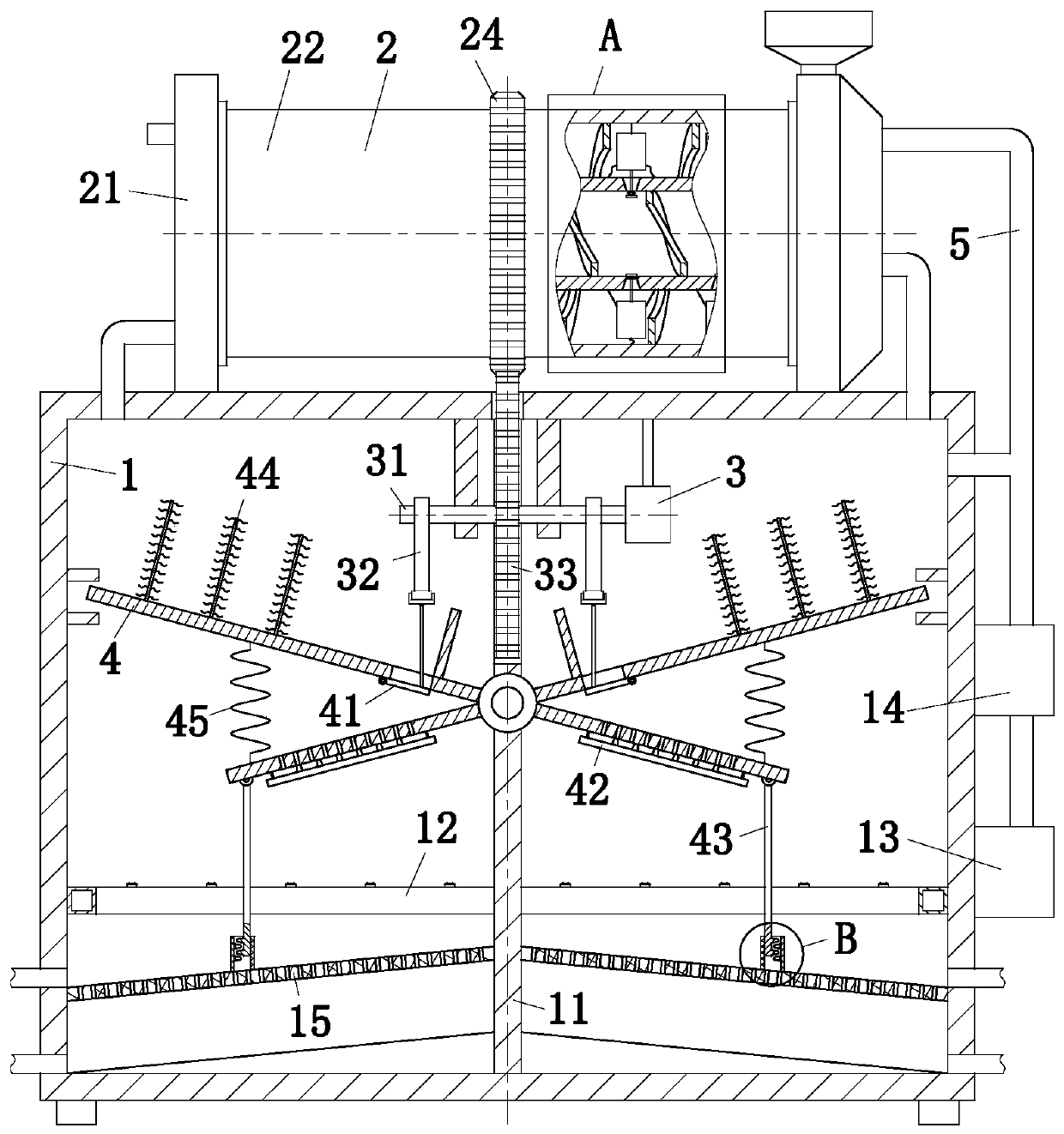

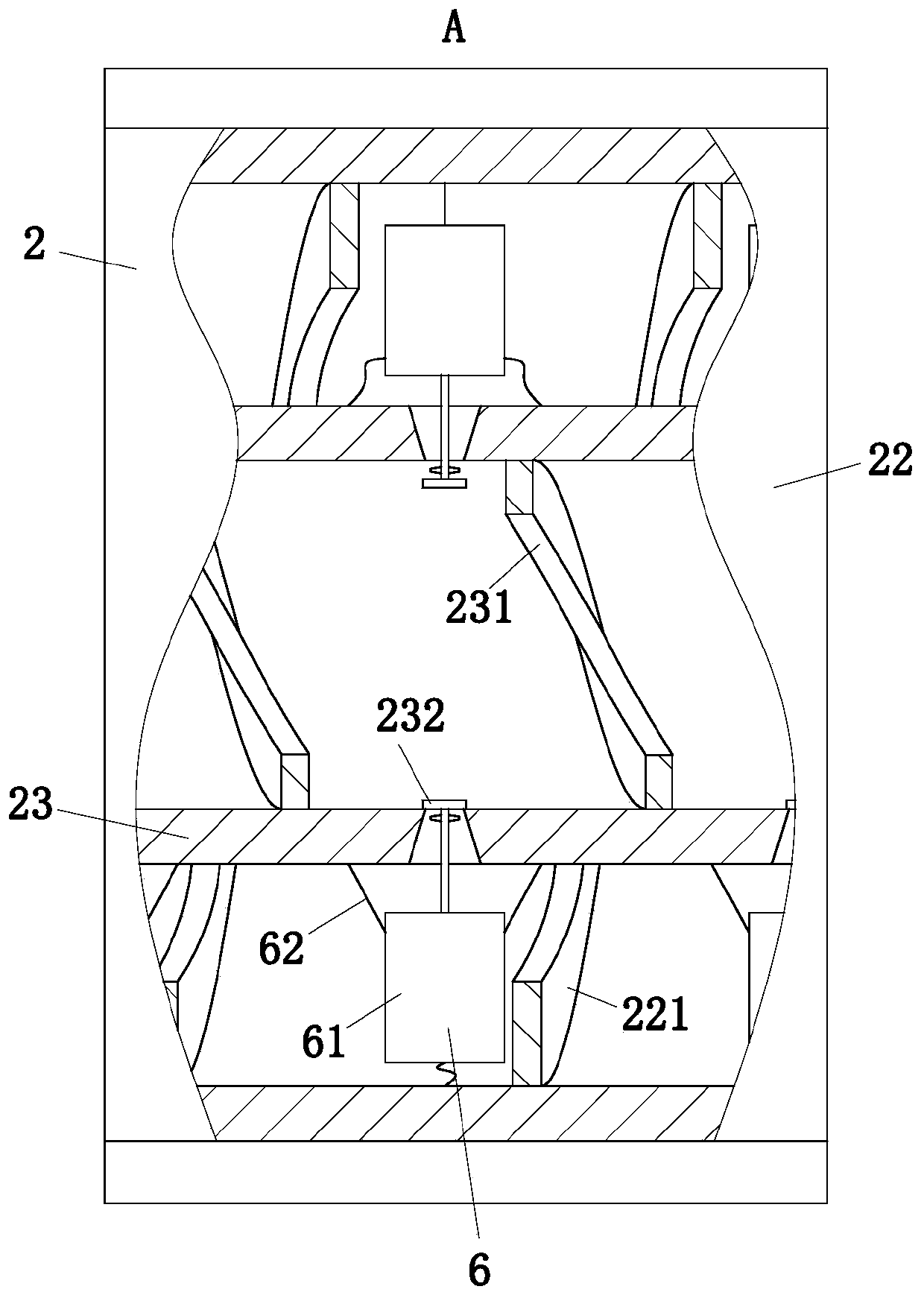

[0035] use Figure 1 to Figure 4 The method for preliminary cleaning of rice of the present invention is described as follows.

[0036] Such as Figure 1 to Figure 4 As shown, the method for preliminary cleaning of rice according to the present invention includes the following steps:

[0037] S1: Take out the screening module of the organic rice finishing screening equipment;

[0038] S2: Take several two ring magnets with different outer diameters, and glue gauze on the inner side of the ring magnet, and there is a gap between the gauze and the inner side of the ring magnet. Install the two ring magnets with different outer diameters in S1. In the screening module of the rice finishing screening equipment, after the outer cylinder and the inner cylinder are on the inner walls, the screening module is reset; through the inner walls of the outer cylinder and the inner cylinder are equipped with ring magnets, the magnetism of the ring magnets The iron nails, iron filings and other sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com