Waste plastic sand remover

A technology of waste plastics and sand machines, which is applied in the direction of solid separation, classification, chemical instruments and methods, etc. It can solve problems such as mechanical failure, sewage impact, and high water dependence, achieve low manufacturing and maintenance costs, and improve sand removal efficiency. , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

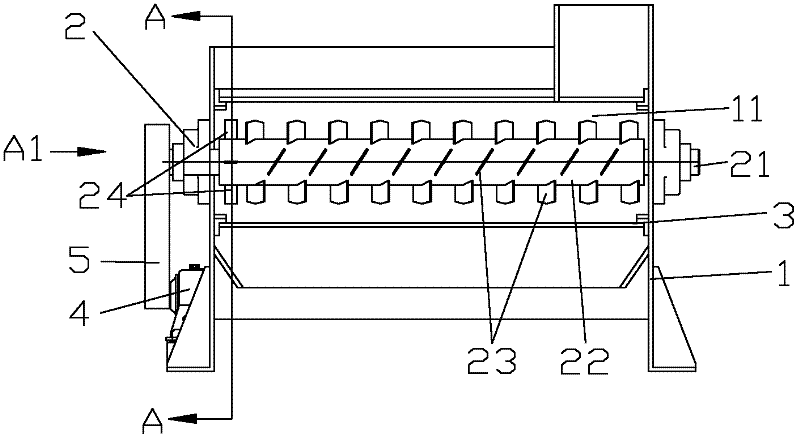

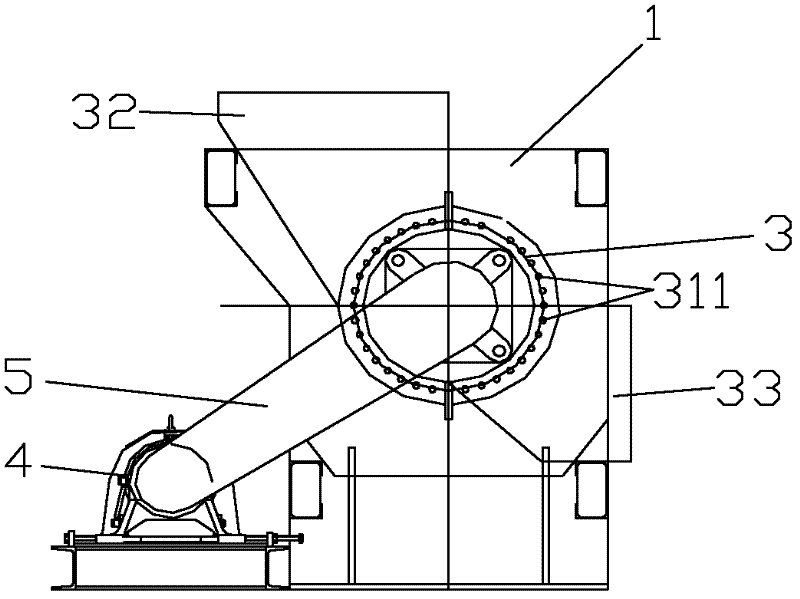

[0025] figure 1 It is a schematic structural view of an embodiment of the waste plastic sand removal machine of the present invention, figure 2 For the waste plastic desanding machine of the present invention figure 1 Schematic diagram of the structure in the direction shown in A1. Such as figure 1 with figure 2 As shown, the waste plastic desanding machine of the present invention includes a frame 1 , a spiral part 2 , a grid 3 and a transmission part 4 . In this embodiment, the transmission part 4 is a motor, which drives the screw part 2 to move through a V-belt 5 and a V-shaped pulley.

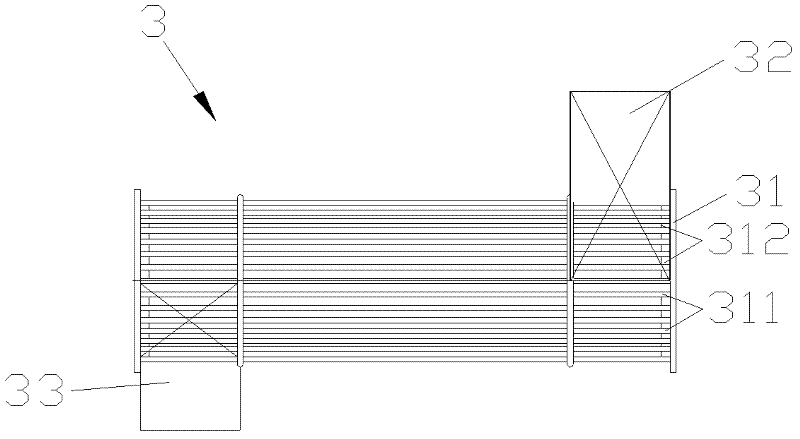

[0026] The frame 1 includes an accommodating inner cavity 11, and a grid 3 is arranged in the cavity. image 3 It is the structural representation of the grid of the waste plastic desander of the present invention, as image 3 In the present embodiment shown, the grid 3 includes a cylindrical body 31, on which several grid pieces 311 are arranged, and the gap 312 between each grid ...

Embodiment 2

[0030] With regard to the waste plastic desand remover provided in Example 1, the removal of sediment attached to waste plastics was studied by using different pitches and conveying blade specifications, see Table 1.

[0031] The calculation method of sediment removal amount is as follows:

[0032] Properly heat the waste plastic to a constant weight to remove the moisture contained in the sediment, and record the value obtained by weighing as W0, then put it into the waste plastic desanding machine to stir and remove sand, weigh the discharged waste plastic and heat it to constant weight. Weight, the value obtained by weighing is recorded as W1, and the discharged waste plastic is manually desanded, heated to constant weight, and the value obtained by weighing is recorded as W2. Sand removal rate%=(W0-W1)×100% / (W0-W2).

[0033] It can be seen from Table 1 that the increase of the screw pitch and the suitable specification of the blade can significantly increase the sand remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com