Sand fishing pipe column and sand fishing working method thereof

A technology of sand tube and sand sink tube, which is applied to earth-moving drilling, drilling equipment, wellbore/well components, etc., can solve the problems of low sand fishing efficiency, increased workover cost, and low fishing volume, etc., and achieves sand fishing operation. The method is simple, the construction period is shortened, and the effect of improving the efficiency of sand fishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings, not to limit the protection scope of the present invention, and all improvements obtained by using the design idea of the present invention belong to the protection scope of the present invention.

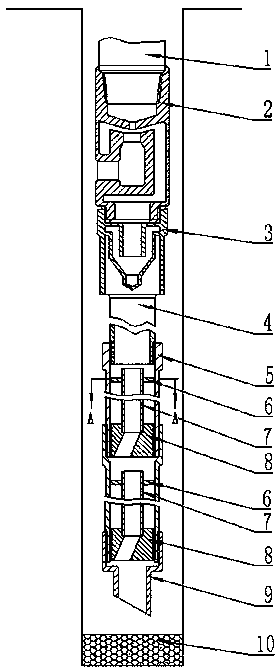

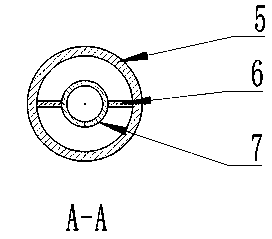

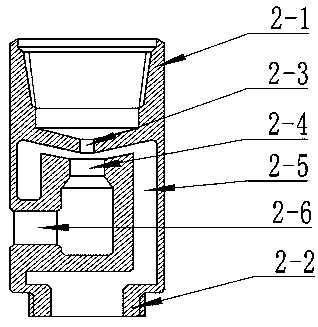

[0029] see Figure 1 to Figure 5 , a sand fishing pipe string includes a suction pump 2, a drill pipe 4 and a sand washing pen point 9, and the suction pump 2 is connected with the swirling flow pipe 3, the sand settling pipe and the sand washing pen point 9 through the drill pipe 4 sequentially from top to bottom , wherein a grit chamber is provided in the grit chamber, a swirl channel is provided in the swirl pipe 3, and at least one grit pipe is connected to the sand fishing string. Both ends of the suction pump 2 are provided with a suction pump upper joint 2-1 and a suction pump lower joint 2-2, which can be connected with the salvage drill string and the swirl pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com