Conic sand making machine comprising concave-convex arc-shaped sand making cavities and sand making method

A conical sand making machine, concave arc technology, applied in the direction of grain processing, etc., can solve the problems of sand grinding bridge, increase, spindle fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

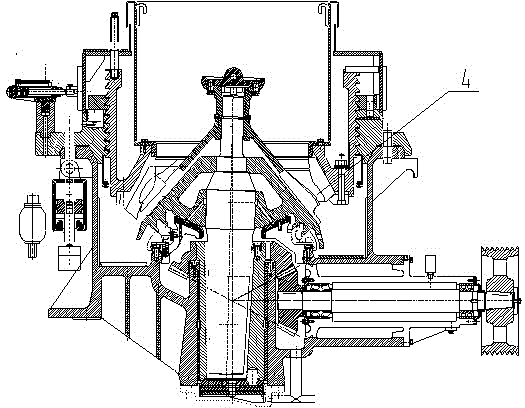

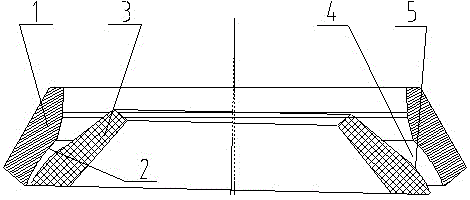

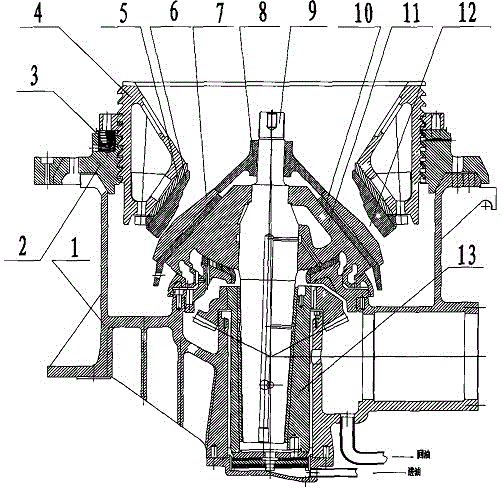

[0011] Embodiment 1: with reference to attached figure 1 and 2 . A conical sand making machine composed of a concave-convex arc-shaped sand making chamber, including a conical sand making machine, the mortar surface 2 of the mortar wall 1 in the sand making chamber 4 of the cone sand making machine and the crushing surface 5 of the crushing wall 3 It is a concave-convex arc-shaped surface, and the mortar wall 1 and the crushing wall 3 are made of high-chromium cast iron, which are cast and formed by high-chromium cast iron and then finished.

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the piercing surface 2 of the piercing socket wall 1 is concave arc-shaped, and the crushing surface 5 of the crushing wall 3 is convex arc-shaped. The radius of the concave arc-shaped grinding surface 2 is 308-328 mm, and the radius of the convex arc-shaped crushing surface 5 is R180-200 mm. The technical effect produced not only improves the efficiency of sand grinding, but also well disperses The grinding force is concentrated on the main shaft to reduce and transfer the sand grinding force, which reduces the energy consumption required for sand grinding. At the same time, the amount of sand produced by sand grinding is large, which avoids the phenomenon of sand bridging.

Embodiment 2-1

[0013] Example 2-1: On the basis of Examples 1 and 2, the radius of the concave arc-shaped piercing surface 2 is 308 mm, and the radius of the convex arc-shaped crushing surface 5 is R180 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com