A Closed Pump Electric Sand Mixing Skid

A closed pump and sand mixing technology, which is used in the production of fluids, wellbore/well components, earth-moving drilling, etc. Due to the complicated structure of the screw conveying device, it can achieve the effect of light weight, reducing the area of the well site and improving the operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

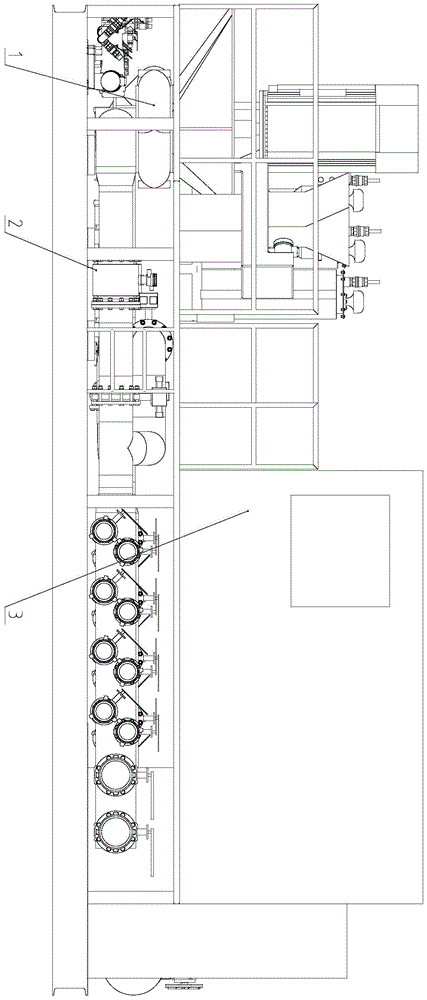

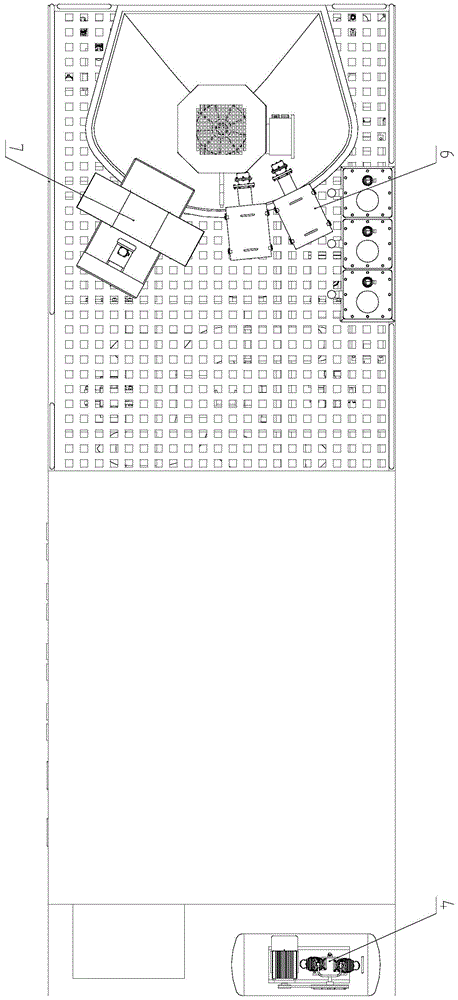

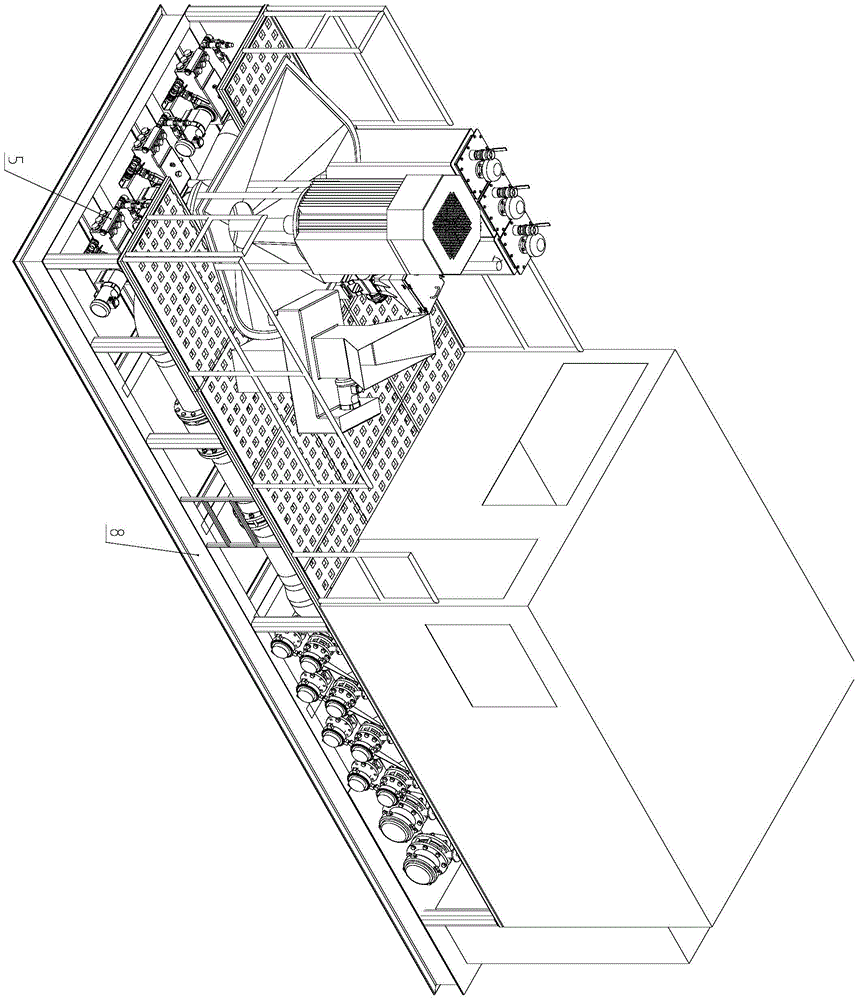

[0040] A closed pump electric sand mixing skid, which includes:

[0041] Closed pump device 1, which is powered by an independently driven variable frequency motor 101, and sand is mixed inside, and the closed pump device 1 is transported by an external separate conveying device;

[0042]The pipeline system 2 is used for the suction and discharge of the fracturing base fluid and the mixed fracturing fluid, and communicates with the closed pump device 1 to deliver the fracturing base fluid to the closed pump device 1 and supply the closed pump device The device 1 discharges the mixed fracturing fluid, and the pipeline system 2 consists of a manifold and a valve;

[0043] The dry addition system 6, the liquid addition system 5, and the fiber addition system 7, which are respectively communicated with the closed pump device 1 and whose addition speed is adjustable, are used to add dry addition agents, liquid addition agents, and fracturing fibers respectively. The fiber adding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com