While Drilling Inner Canister

A technology of drilling while drilling and inner barrel, which is applied in the field of oil field drilling and workover, and can solve problems such as excessive drilling fluid, depletion of oil production in oil wells, sticking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the technical means and functions adopted by the present invention to achieve the predetermined invention goal, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

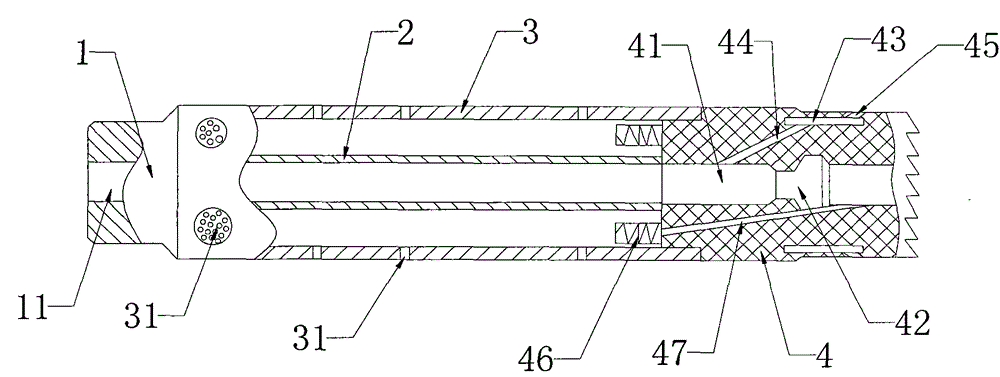

[0018] Such as figure 1 As shown, an inner canister while drilling includes an upper joint 1, an inner cylinder 2, an outer cylinder 3 and a reverse circulation milling shoe 4. The center of the upper joint 1 is provided with a circular channel 11, and the upper joint 1 is screwed on the outer On the top of the cylinder 3, the inner cylinder 2 is set inside the outer cylinder 3 and communicates with the circular channel 11 of the upper joint 1, and the top of the reverse circulation milling shoe 4 is screwed to the bottom of the outer cylinder 3;

[0019] The side wall of the outer cylinder 3 is provided with a plurality of drain holes 31 of different sizes and shapes. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com