Inclined plate type rotational flow sand setting system

A swirl sand settling and inclined plate technology, applied in the field of sand settling system, can solve the problems of low sand settling efficiency, lower processing efficiency, and difficult continuous operation of the sand settling tank, so as to increase the concentration of volatile suspended matter and improve the sand settling Efficiency, the effect of improving the efficiency of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

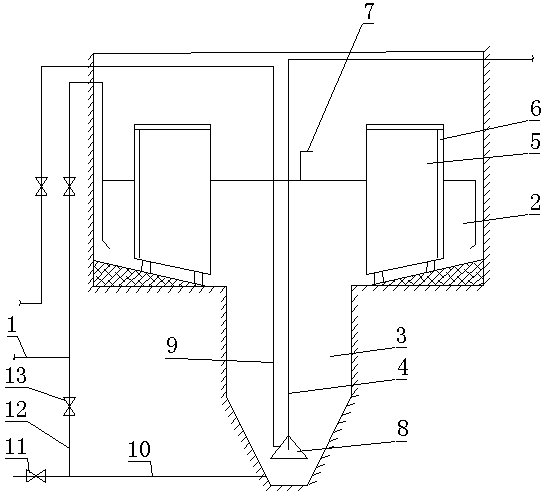

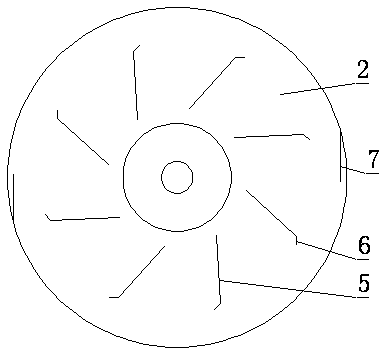

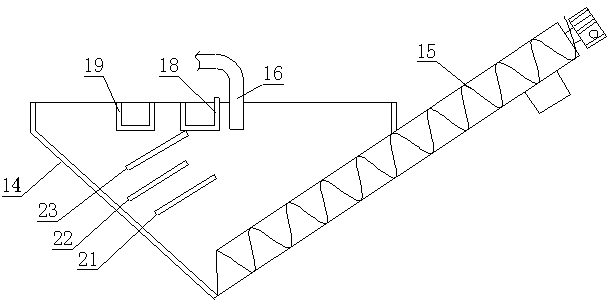

[0028] In this specific embodiment, if Figure 1 to Figure 4As shown, a slanting plate type swirl grit settling system includes a pool body, the lower half of the pool body is a sand bucket 2 with a conical inner cavity, and the upper half of the pool body is a cylindrical inner cavity with a diameter larger than the sand bucket 2. The grit chamber 3 of the cavity has an inflow port and an outflow port above the pool body; it also includes a sand lifting pipeline 4 and a sand lifting gas distribution structure vertically arranged in the middle of the pool body, and the lower end of the sand lifting pipeline 4 extends to the bottom of the sand bucket 2 to lift The upper end of the sand pipeline 4 is connected with the sand-water separator, and the bottom surface of the grit chamber 3 is provided with a slant plate sedimentation structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com