On-line detection method of continuous casting billet surface quality

A technology of surface quality and detection method, applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc. The effect of fast storage and processing speed, high system stability and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

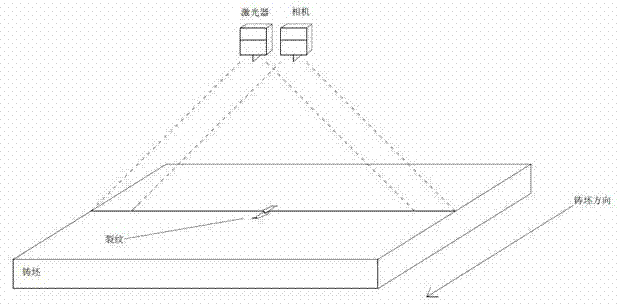

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Considering the complexity of the site environment, the continuous casting slab surface quality testing equipment is installed in a bridge type, and the bridge itself adopts a semi-closed structure to shield the radiant heat of the high-temperature continuous casting slab; the testing equipment is protected by a waterproof and dustproof testing box , The protection level of the detection box reaches IP54. The cooling method of the test box can be air-cooled, water-cooled and air-conditioned constant temperature control, etc., through these multiple protections, the working environment temperature of the test equipment does not exceed 35°C.

[0031] The temperature of the on-line continuous casting slab detected on site is above 800°C, which is itself a luminous body. In order to avoid the influence of its own luminescence on imaging, the present invention uses a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com