Lock support transferring die structure

A technology of transferring molds and locking supports, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inability to realize automatic production, high labor intensity of workers, low work efficiency, etc., saving labor and equipment, and compact structure. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described below in conjunction with the drawings.

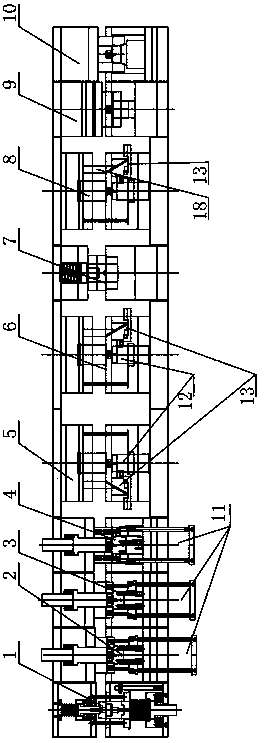

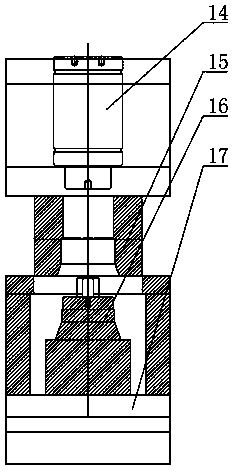

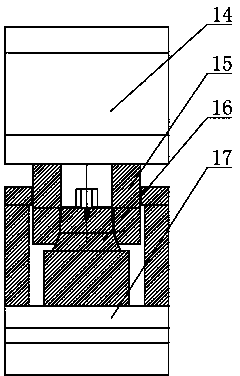

[0015] Such as figure 1 , figure 2 with image 3 As shown, a lock support transfer mold structure of this embodiment includes a frame, on which a feeding device 1, a first stretching mold 2, a second stretching mold 3, and a shaping device are successively installed from left to right. Presser foot die 4, first side punch die 5, second side punch die 6, third side punch die 7, trimming die 8, punching and typing die 9 and tie foot die 10, installed in feeding device 1 There are sensors, the middle of the above-mentioned molds convey the workpiece through the conveyor belt, and the fixture for clamping the workpiece is installed in the middle of each group of molds. The structure of a single group of molds is: including upper mold assembly and lower mold assembly, and the upper mold assembly passes through The nitrogen spring pressure material assembly 14 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com