Method and system for reworking composite laminate and automated tape placement machine

A composite material layer, composite material technology, used in the field of reprocessing composite material laminates and systems and automatic tape laying machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

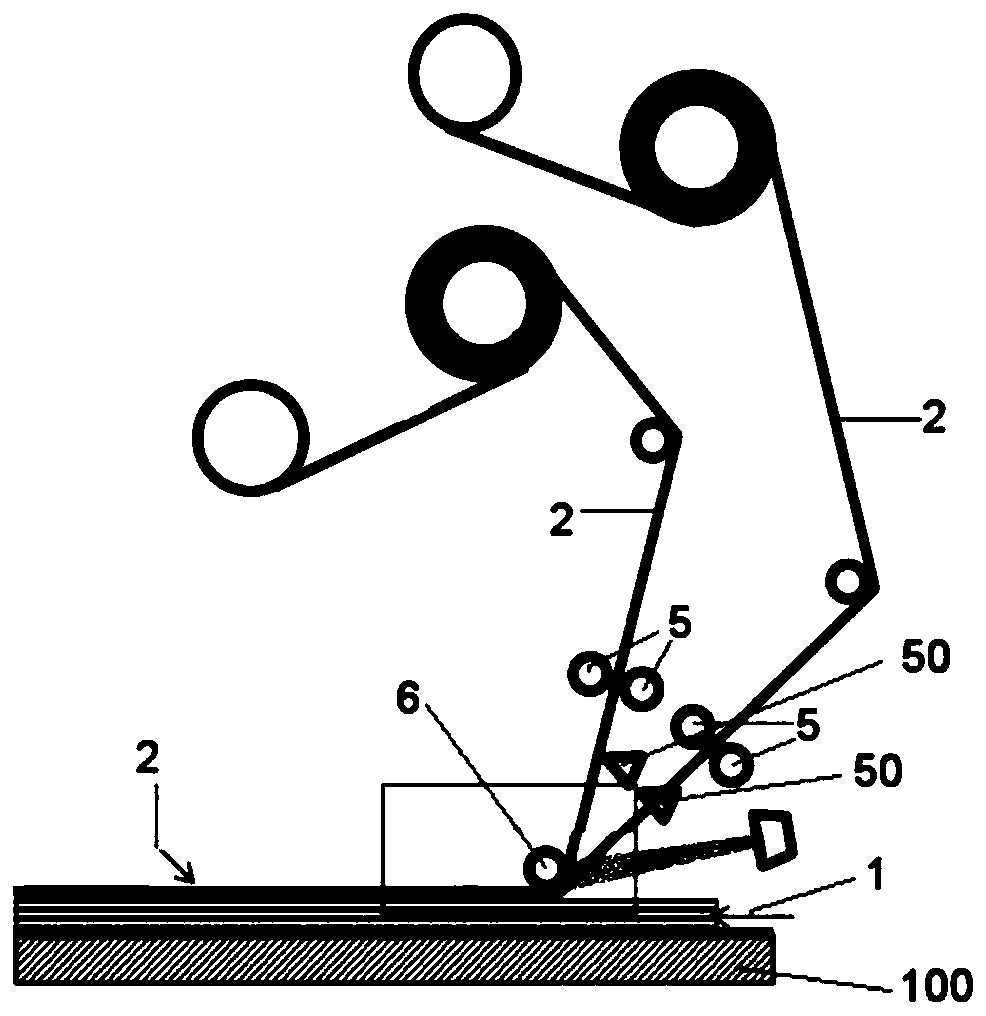

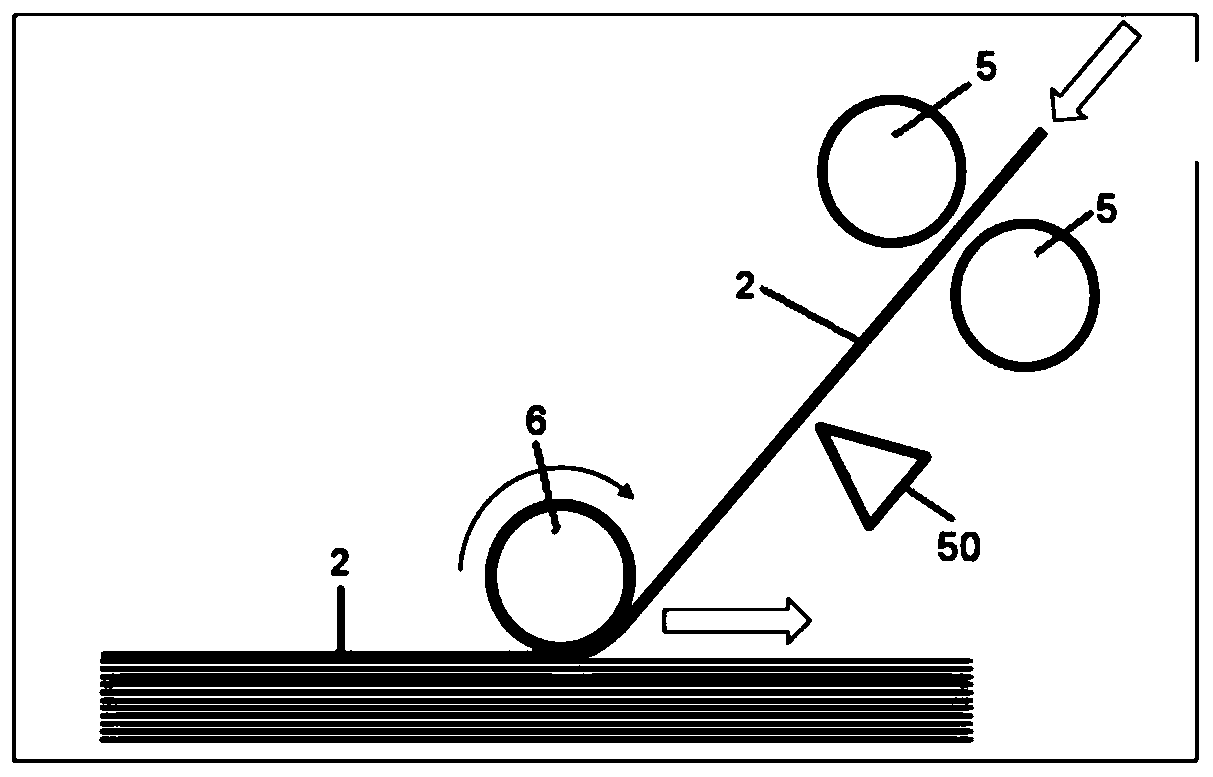

[0041] figure 1 A known automatic tape laying machine is disclosed which passes the lamination tape 2 through the lamination tape 2 by means of two heads comprising at least a pressure roller 6 , an additional roller 5 and a cutter 50 to produce a laminate 1 on a mold 100 . exist figure 2 , the belt 2 is clamped with additional rollers 5 and cut with a blade or other system to end the layup.

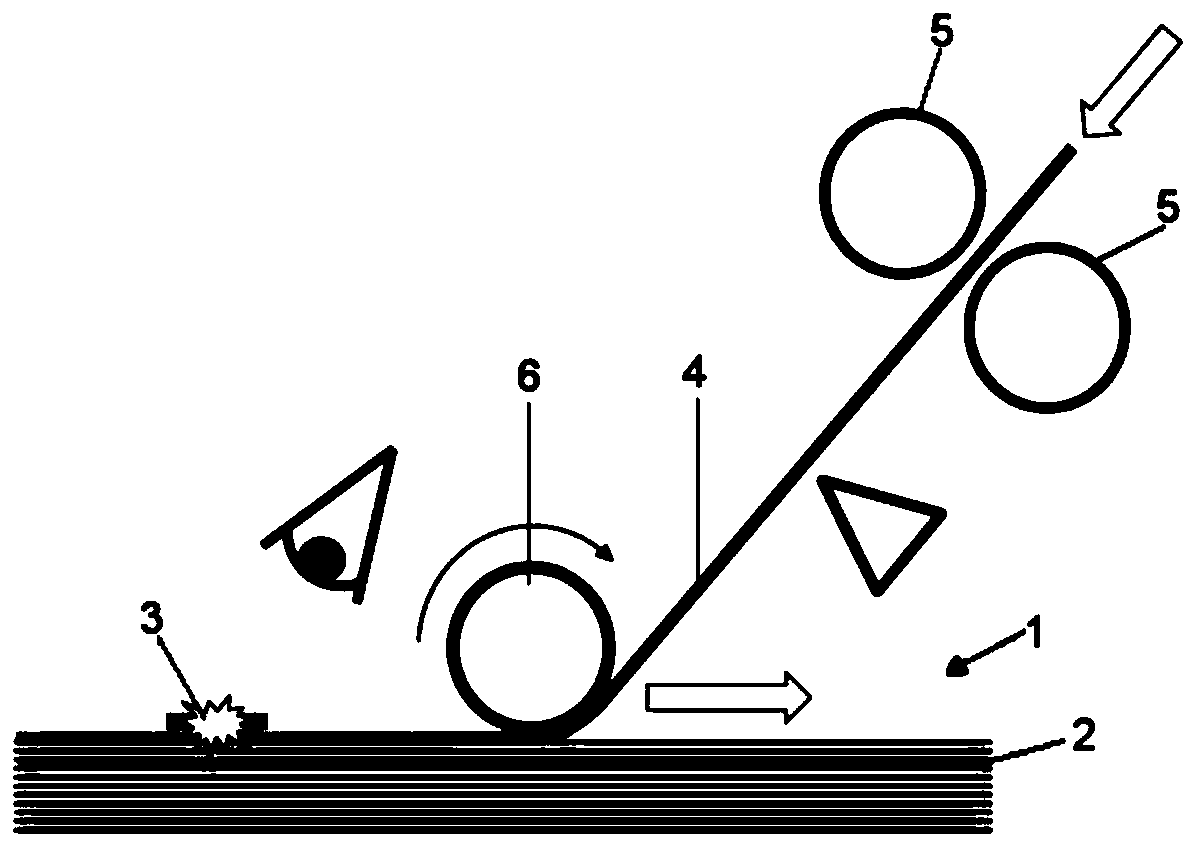

[0042] image 3 The detection of a defect 3 on the strip 4 during laying of the strip 4 is shown. Then, if Figure 4 Laying of the defective strip 4 continues as shown until the strip 4 exceeds the production length L of the strip 4 . By rotation of the additional roller 5, the defective belt 4 is placed between the pressure roller 6 and the laying surface to continue the laying operation.

[0043] In a multi-head machine, when laying multiple strips 2, all strips 2 except the defective strip 4 are laid and cut according to the original designed length of the part, and the defecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com