Metal glasses legs with spiral lines

A spiral type and spectacle leg technology, which is applied in glasses/goggles, optics, instruments, etc., can solve the problems of lack of design sense, inability to disassemble and replace, glasses slipping, etc., so that it is not easy to skin allergies, convenient for automatic processing, rich in metal Gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

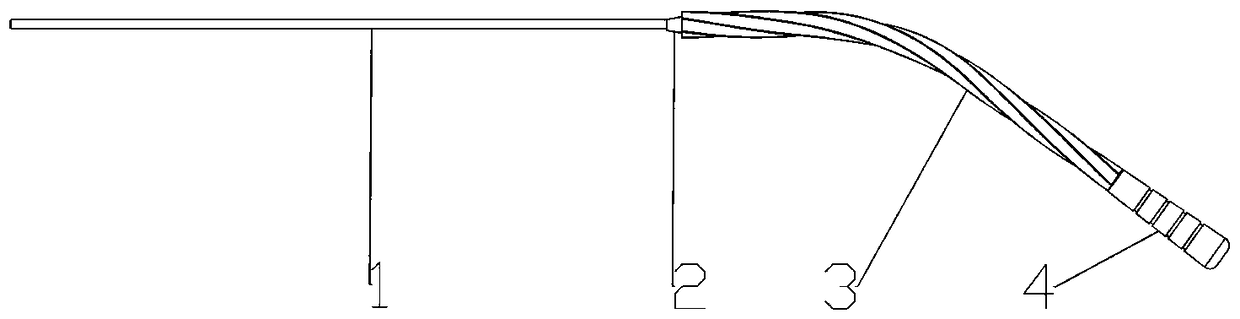

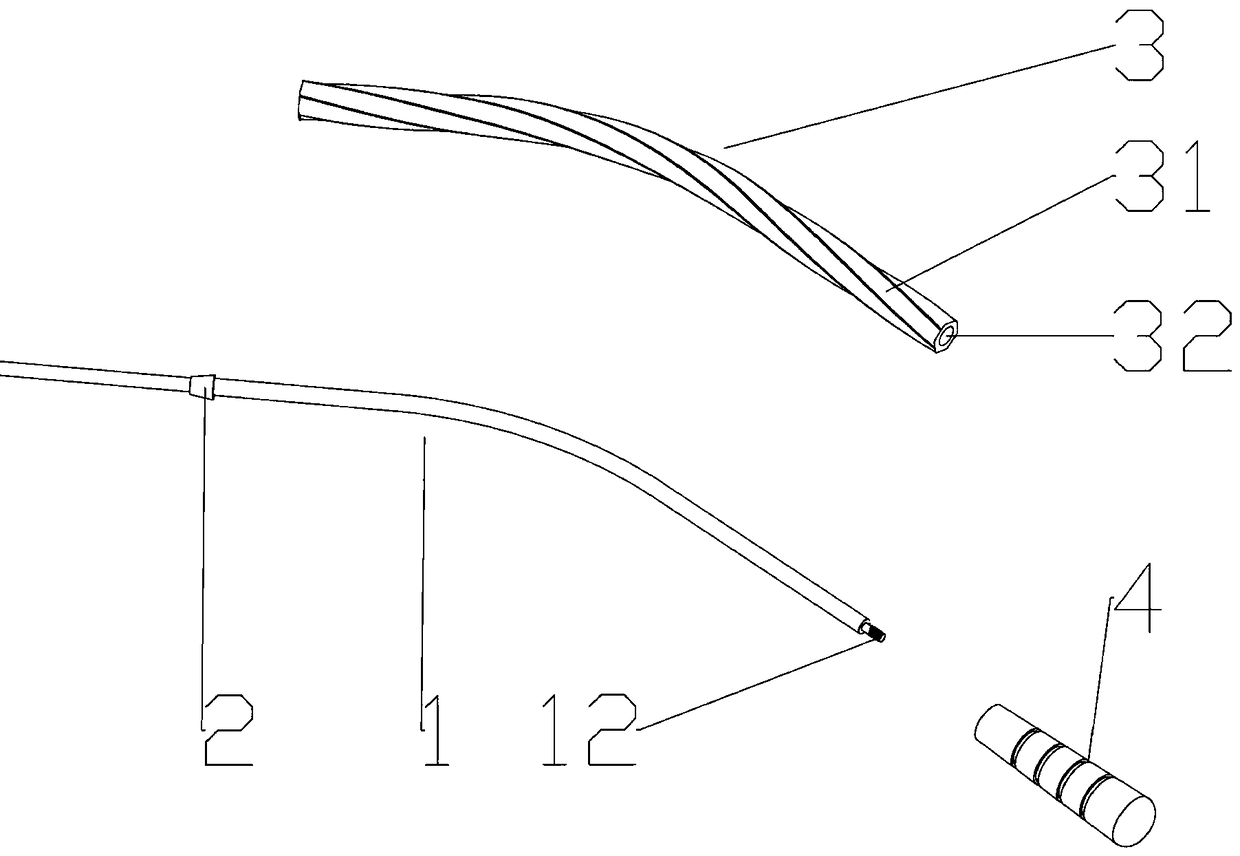

[0012] Such as figure 1 with figure 2 The metal spectacle leg with spiral texture shown includes a spectacle shell 1, and also includes a spiral spectacle temple cover 3 and a spiral locking sleeve 4; , the spiral locking sleeve 4 is located at the end of the glasses shell 1; the spiral temple cover 3 includes an inner sleeve 32 sleeved on the glasses shell 1 and a spiral wire 31, and the spiral wire 31 is wound around the In addition to the inner cover 32 , the spectacle case 1 is also provided with a positioning protrusion 2 for fixing the screw-type spectacle temple cover 3 . The screw-type spectacle temple cover 3 and the spectacle shell 1 can be processed separately, then socketed and tightened to complete the assembly, and can be disassembled and replaced according to needs, which is convenient for automatic processing and production. The screw locking sleeve 4 at the end can increase the weight of the end of the spectacle leg, Balance the overall weight of the glasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com