Winding wire, winding and preparation method of winding wire

A wire winding and wire technology, which is applied in the manufacture of coils, coils, inductors/transformers/magnets, etc., can solve the problems of reducing production costs, large transformer space, unfavorable transformer power density, etc., to improve power density and smooth wire surface , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention is described in further detail below in conjunction with accompanying drawing and specific embodiment: present embodiment is carried out under the premise of technical solution of the present invention, has provided embodiment and operation process, but protection scope of the present invention is not limited to following Example.

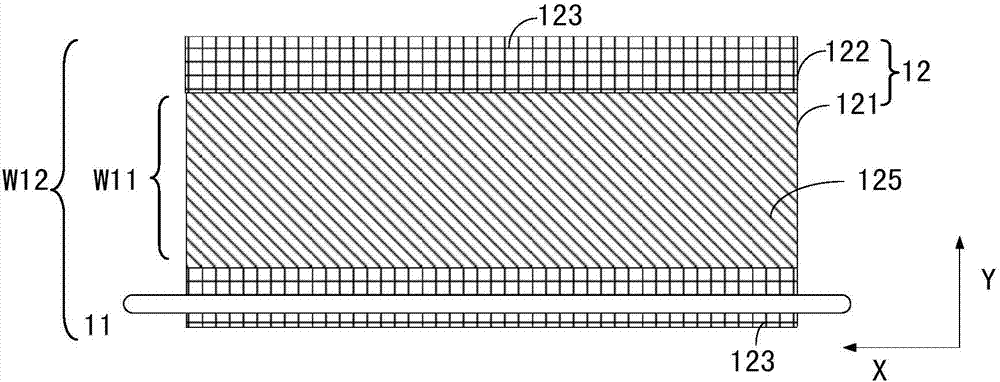

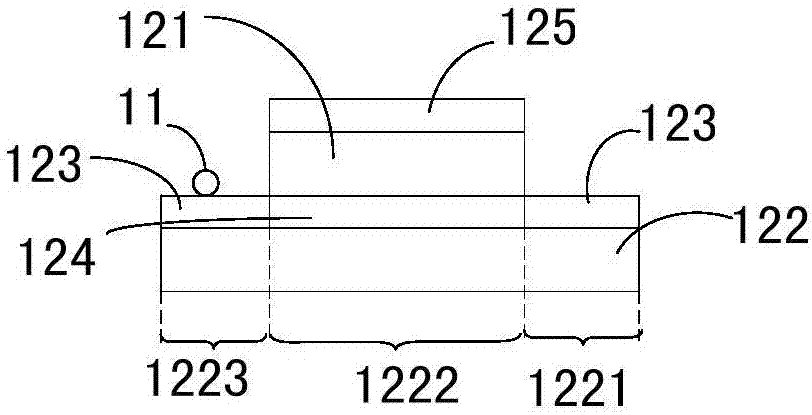

[0074] Please refer to Figure 1-2 , figure 1 It is a structural schematic diagram of the first embodiment of the winding wire of the present invention, figure 2 for figure 1 side view. Such as Figure 1-2 As shown, the wire winding of the present invention includes a wire 11 and an insulating structure 12. The wire 11 can be a basic insulated single-strand wire or a basic insulated multi-strand wire, etc., and the insulating structure 12 is wrapped around the covered wire 11. The insulating structure 12 includes: a first insulating A layer 121 and a second insulating layer 122; the first insulating layer 121 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com