Numerically controlled cutting and molding table for lost foam

A technology of lost foam and cutting table, which is used in casting molding equipment, metal processing, casting molds, etc., to achieve the effect of high surface smoothness, safe operation and large processing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

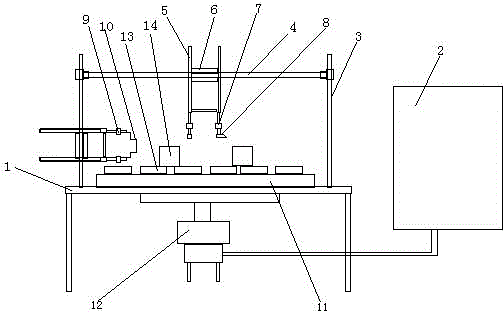

[0023] Such as figure 1 Shown, a kind of lost pattern numerical control cutting plastic table, comprises cutting table 1, numerical control controller 2, the lost die blank fixing device that is arranged in cutting table 1 and the lost die cutting plastic device that is arranged on cutting table 1 top, described The lost die cutting device includes: a vertical plastic cutting device and a horizontal plastic cutting device; the vertical plastic cutting device includes a vertical adjustment rod 3 arranged at a diagonal position of the cutting table 1, and two vertical adjustment rods 3 The upper part is provided with a positioning bar 4, and a vertical fixing frame is arranged on the positioning bar 4. Specifically, the vertical fixing frame is H-shaped; further comprising: 2 vertical fixing frames 5 and 2 vertical fixing frames The transverse connecting rod 6 between the rods 5 is connected to the positioning cross bar 4 . The bottom of the vertical fixed frame is provided wi...

Embodiment 2

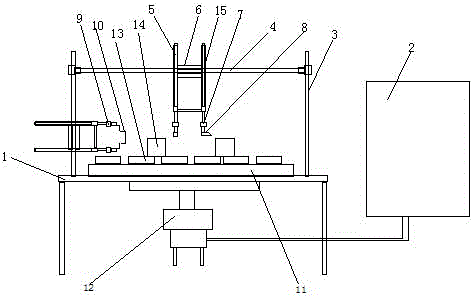

[0030] On the basis of Example 1, such as figure 2 As shown, in order to facilitate processing and adjustment according to the size of the white plastic mold, the vertical fixing frame 5 is arranged in a group of sliding sleeves 15 connected to the positioning crossbar 4 . And the limit is fixed by bolts. The sliding sleeve 15 is a semicircular pipe body, and is provided with a fixing hole to connect with the positioning cross bar 4 and the vertical fixing frame 5 .

[0031] The lost foam numerical control cutting and plastic table has a simple structure and is convenient to use, and the produced lost foam has high surface smoothness and large processing output. It is especially suitable for the production of large quantities of lost foam. At the same time, the operation is safe, and it is not easy to cause industrial accidents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com