NC perforating machine for arc plank

A technology of circular arc plate and slit, which is applied in the direction of paper/cardboard containers, container manufacturing machinery, box production operations, etc. It can solve the problems of difficult product quality assurance, low product accuracy, and low processing output, so as to promote the market , Improve processing output and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the invention:

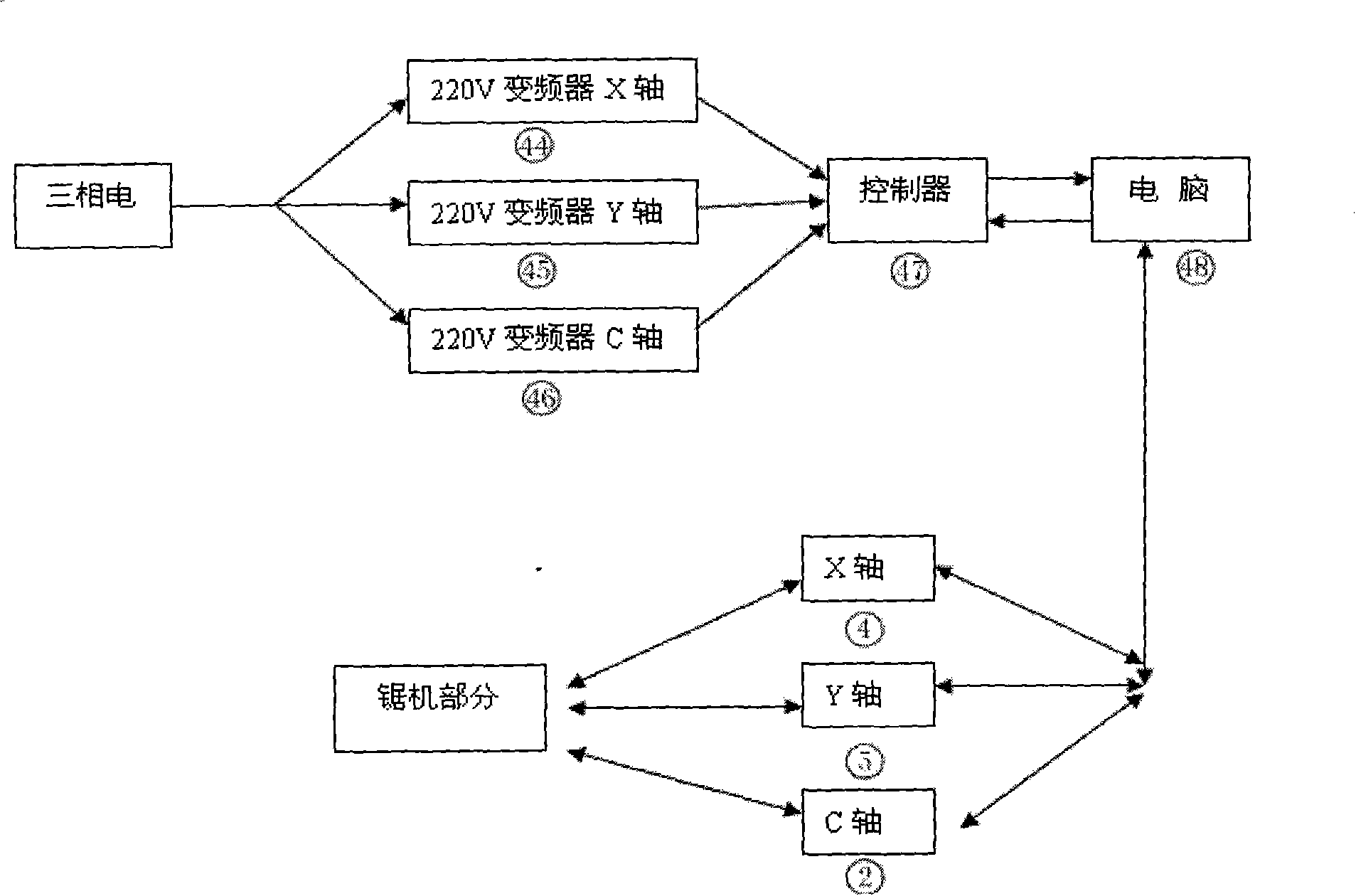

[0010] It uses two-dimensional software CAD and three-dimensional software PORE to draw drawings, and applies them to computers through electrical parts such as computers and servo motors, and controls the sawing machine through mechanical instructions to realize automatic rotation, cutting, and one-time sawing of arc plates. A numerically controlled machine.

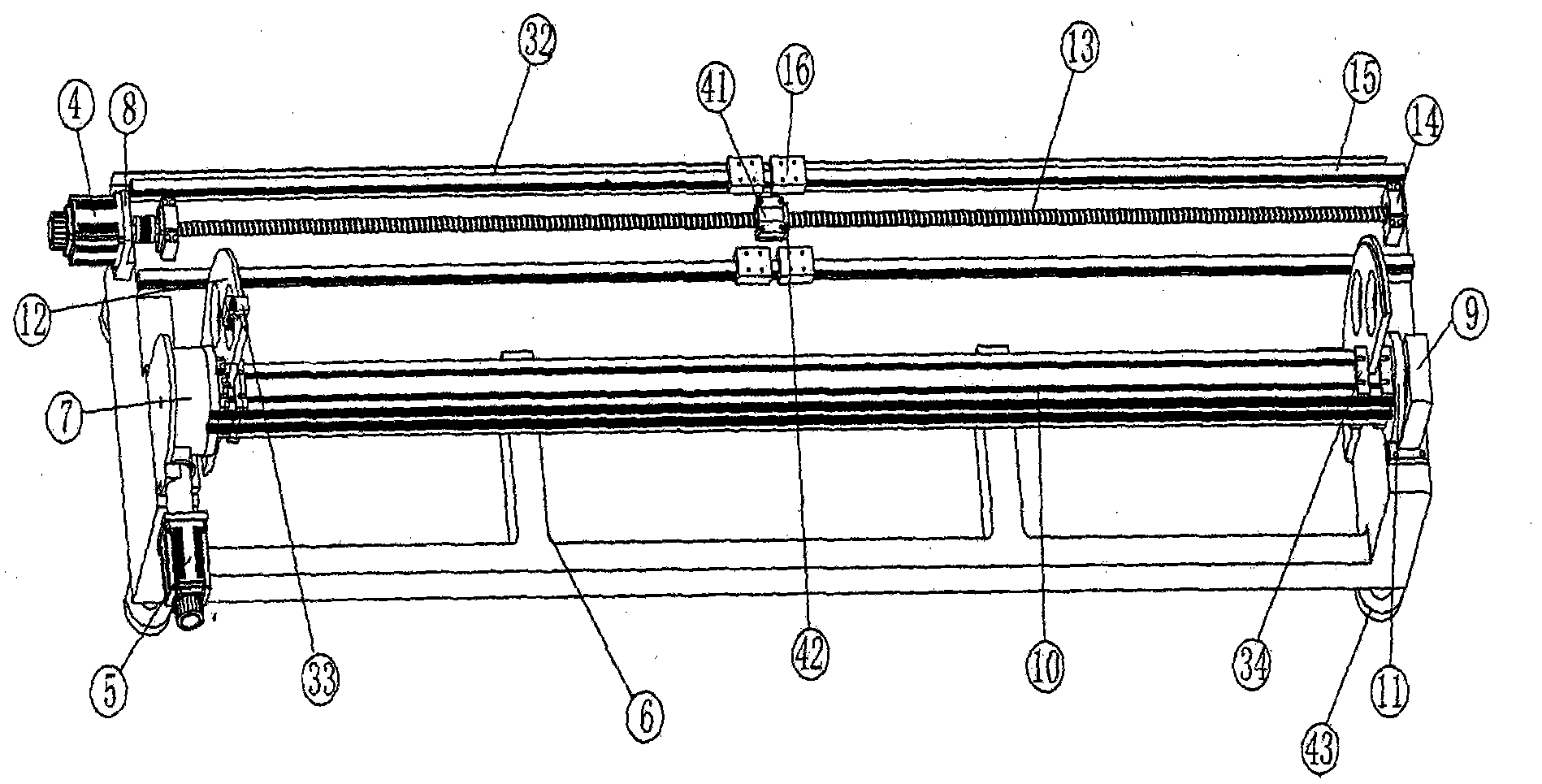

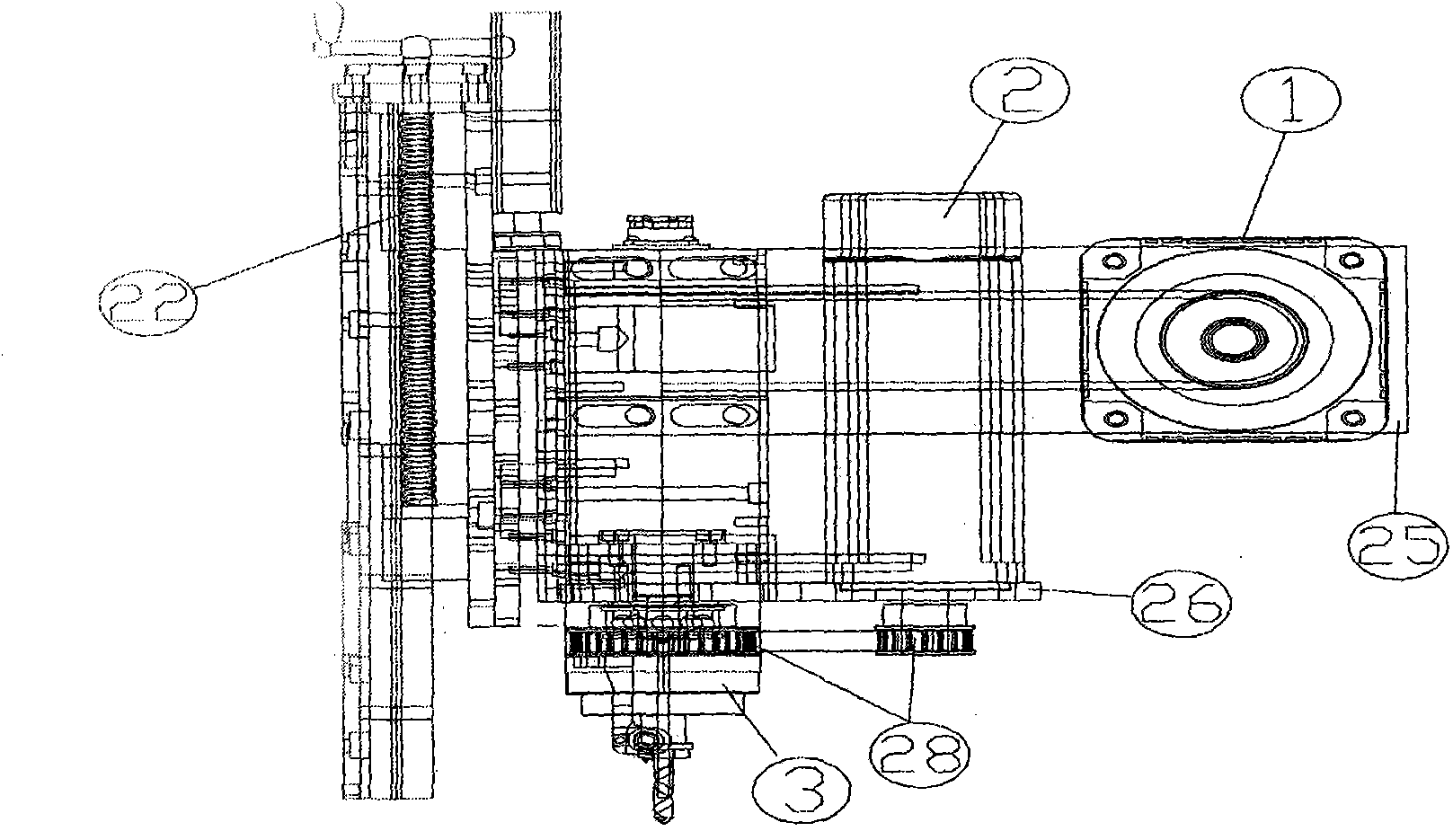

[0011] The sawing machine part consists of (1) host motor, (2) C-axis rotating motor, (3) high-speed spindle electric drill, (4) X-axis transverse motor, (5) Y-axis indexing motor, (6) bed, (7) ) indexing plate, (8) transverse screw motor base, (9) rotary bushing box, (10) rotary shaft, (11) indexing plate pair, (12) supporting plate connecting plate, (13) transverse screw , (14) screw support seat, (15) horizontal guide rail, (16) horizontal slider, (17) lower sliding plate, (18) middle sliding plate, (19) sawing upper sliding plate, (20) drilling upper sliding Plate, (21) cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com