Injection mold for processing elongated push rod

A technology for injection molds and push rods, which is applied in the field of injection molds for processing slender push rods. It can solve the problems of high output and poor processing and molding efficiency, and achieve the effects of compact structure, reduced scrap rate, and guaranteed product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described below in conjunction with accompanying drawing.

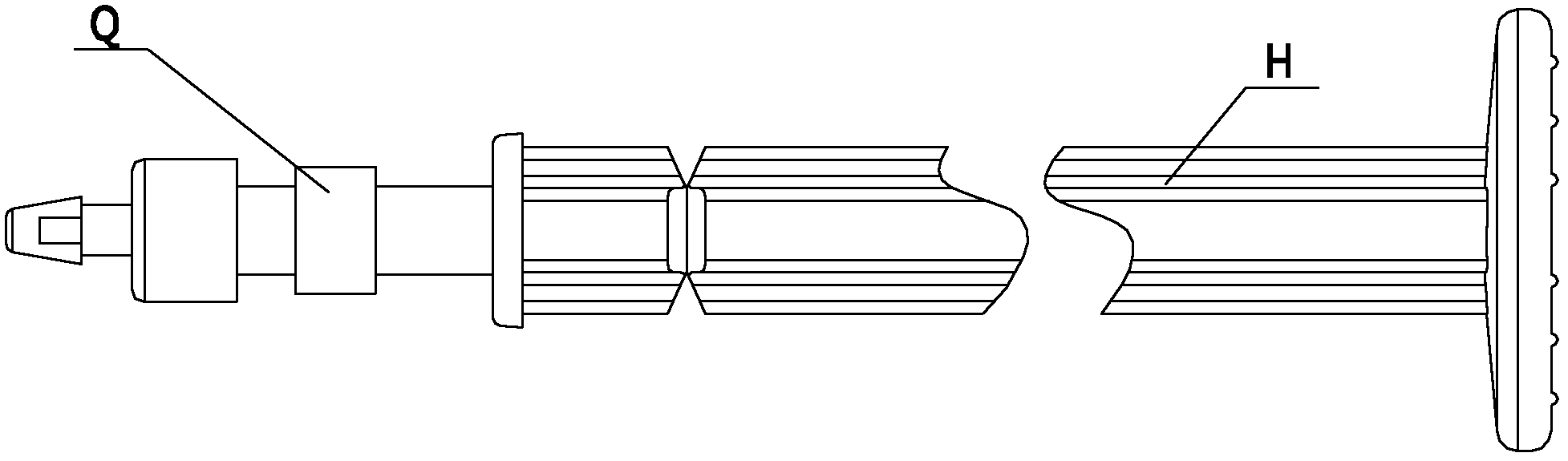

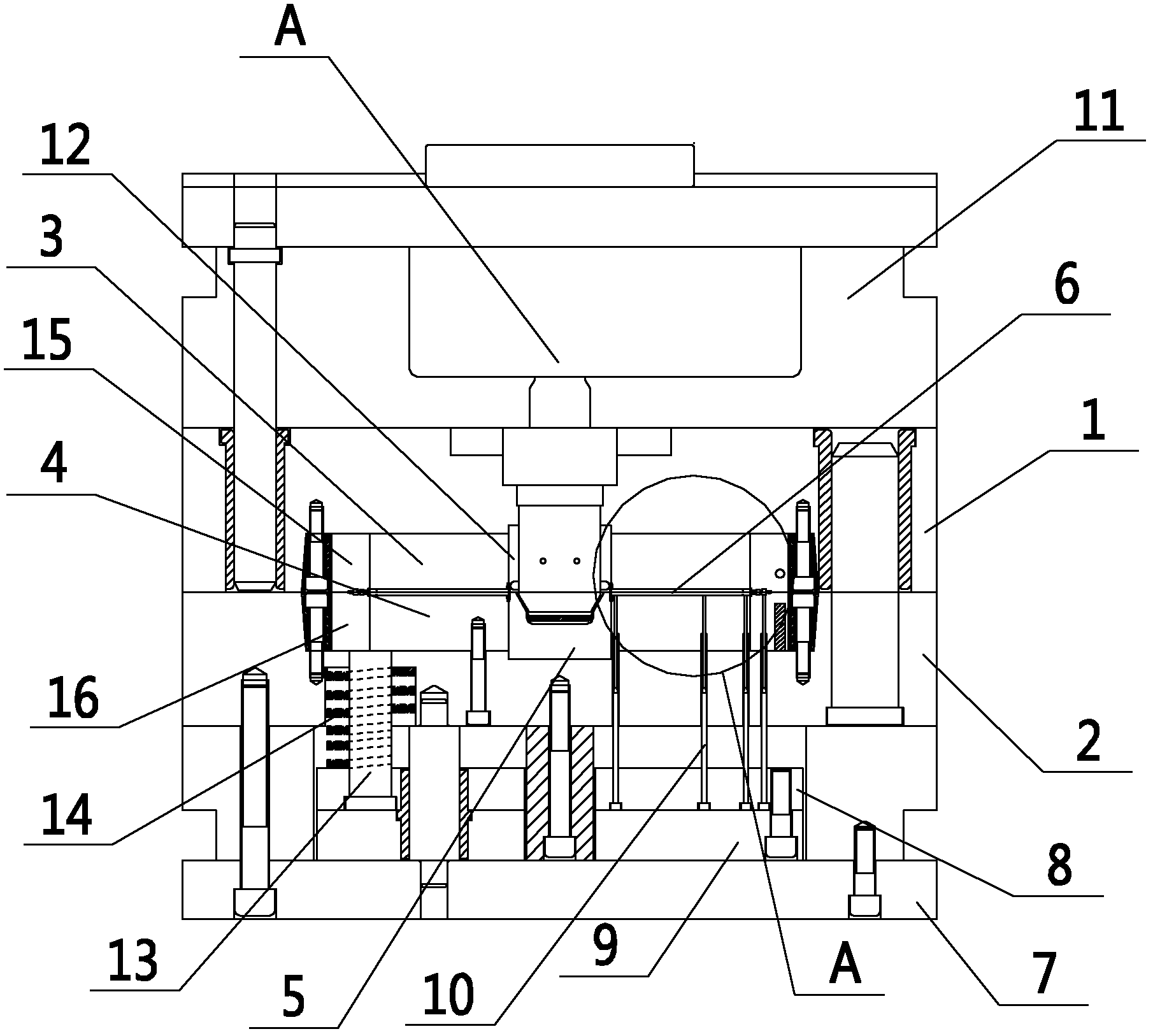

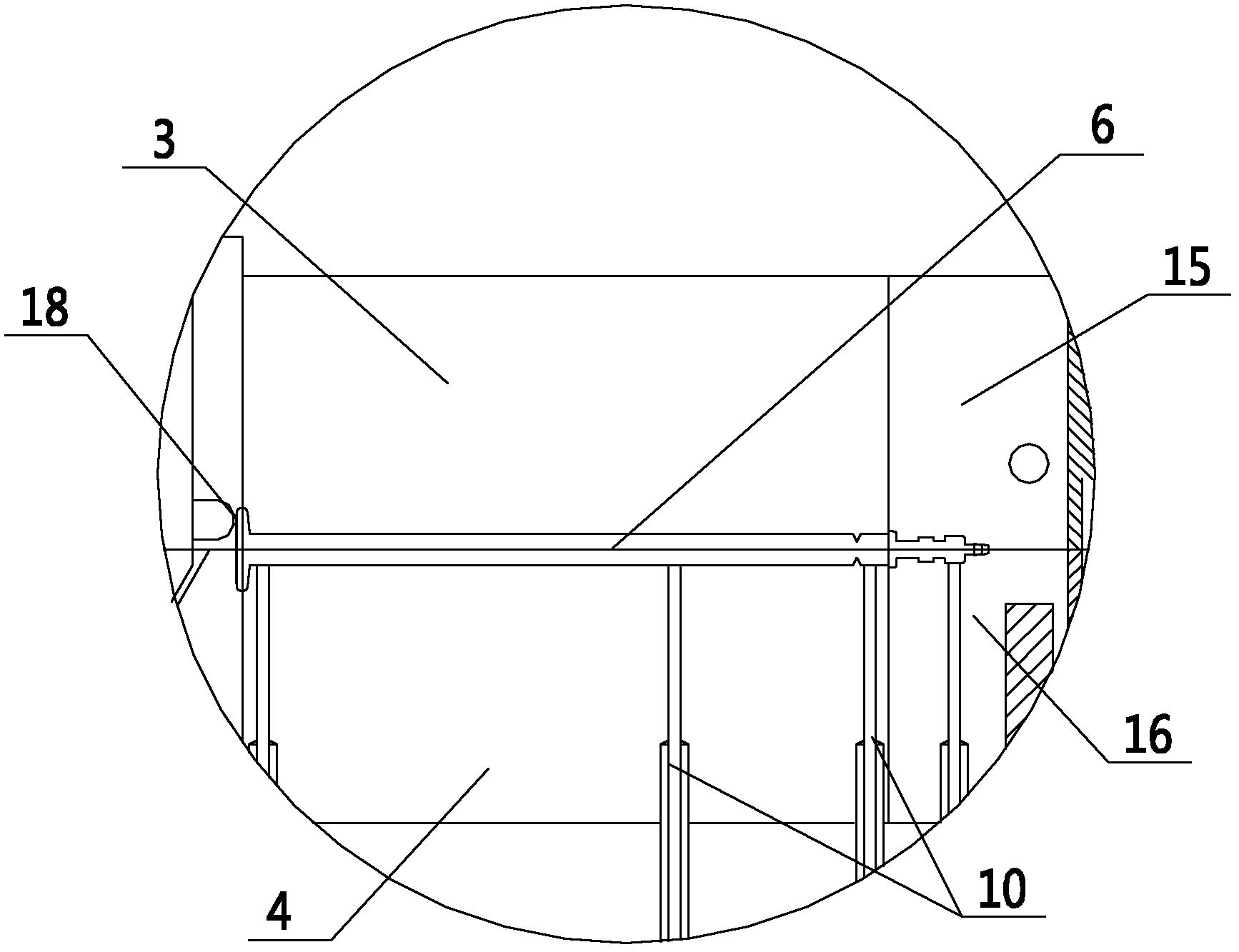

[0018] with processing attached figure 1 The pushrod shown in is an example, attached Figure 2-5 It is an injection mold for processing slender push rods according to the present invention, including a fixed template 1, a movable template 2, a movable mold core 17, a fixed mold core, an ejection mechanism, a hot runner system and a movable mold middle insert 5; Cavity 6 is formed between the movable mold core 17 on the movable template 2 and the fixed mold core on the fixed template 1 that matches with it; the fixed mold core and the movable mold core 17 are four pairs, and each pair of mold cores is Arranged in a rectangular array on the fixed template 1 and the movable template 2; the sprue 18 of each pair of mold cores is located in the middle of the template; the middle insert 5 of the movable mold is two pieces, and they are all fixed on the movable template 2 On the fixed templ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com