Automatic processing device of bamboo shavings

A technology of processing device and transmission device, applied in metal processing and other directions, can solve the problems of high loss rate of raw materials, high labor intensity, low processing efficiency of bamboo and rutabaga, and achieve high utilization rate of raw materials, high processing efficiency, and improved processing efficiency. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

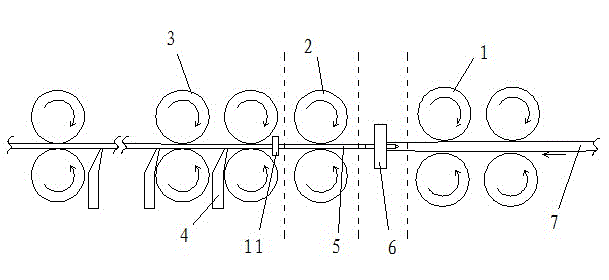

[0028] see figure 1 , automated bamboo processing device, including:

[0029] The feeding device 1 has several groups of bamboo transmission devices arranged horizontally, and each group of bamboo transmission devices includes transmission rollers and passive rollers arranged up and down, and a space for bamboo 7 to pass is provided between the transmission rollers and passive rollers. Through the design of the feeding device 1, the first operation of cutting the bamboo separately is solved in the traditional bamboo processing, so that the whole production process becomes simpler.

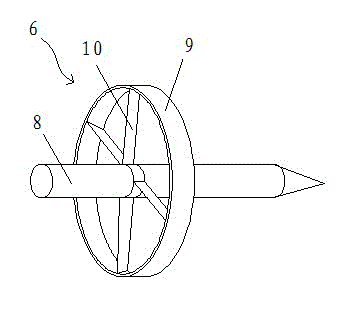

[0030] Bamboo 7 is processed into the split bamboo device 6 of bamboo chip 5, is placed in the outlet end of feeding device 1, please refer to image 3 , which includes an annular sleeve 9, a positioning rod 8 is arranged at the center of the annular sleeve 9, and the end of the positioning rod 8 facing the feeding device 1 has a cone angle of 20-30 degrees.

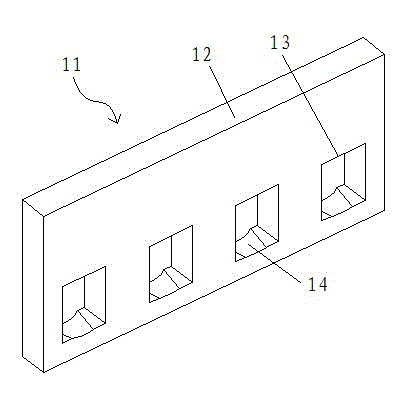

[0031] Several blades are evenly dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com