Integrated husking and peeling machine for lotus seeds

An all-in-one machine and lotus seed technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of unstable transmission and short service life of the machine, and achieve the effects of avoiding rust and rot, improving processing quality, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

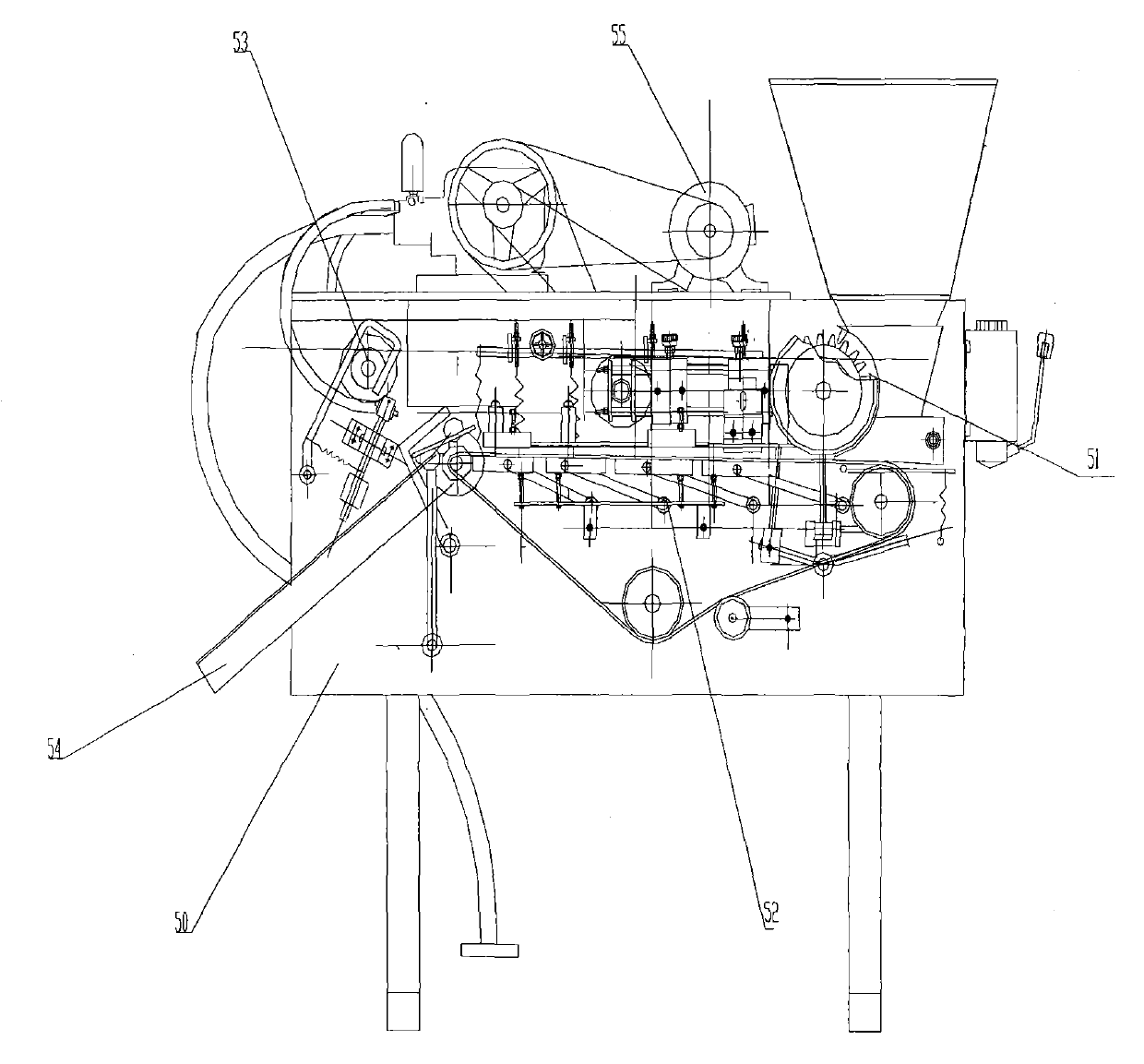

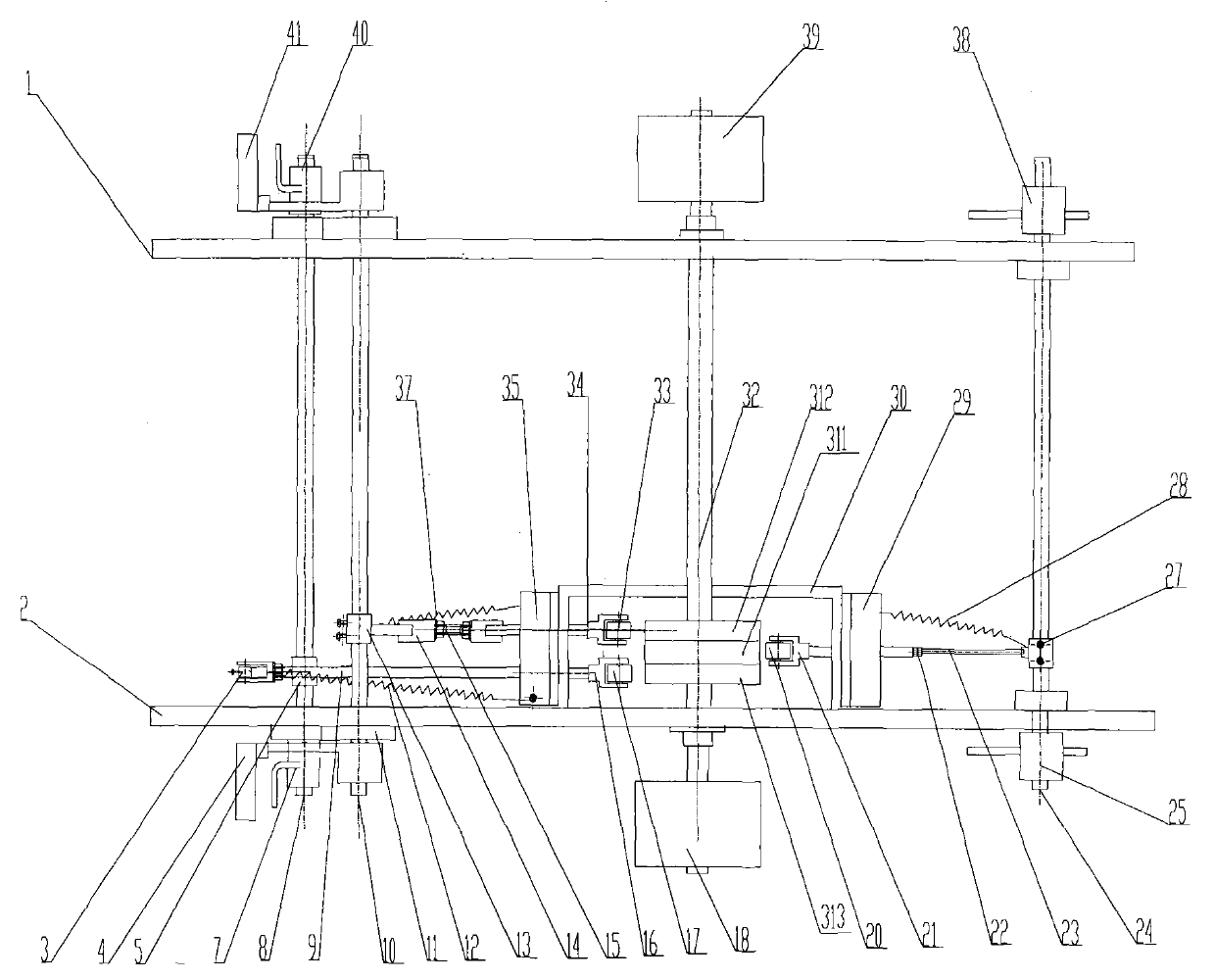

[0015] refer to Figure 1 ~ Figure 2 , a lotus seed shelling and peeling integrated machine, comprising a frame 50, the frame 50 is provided with a feeding device 51, a shelling device 52, a peeling device 53, a discharging device 54, a cam transmission mechanism and a transmission device, the The feeding device 51 and the discharging device 54 are arranged at both ends of the conveying device respectively, and the conveying device includes a conveying wheel and a conveying belt, and the shelling device 52 and the peeling device 53 are successively arranged at the two ends of the conveying device. Above the working surface of the conveyor belt, the frame 50 includes two wall panels, the conveyor belt is located on the outside of the two wall panels, the cam transmission mechanism is installed between the two wall panels, and the cam Transmission mechanism comprises fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com