Lashing bar numerical control hydraulic high-speed horizontal forging machine and using method thereof

A technology for binding rods and flat forging machines, which is applied to forging presses, forging presses, driving devices of forging presses, etc., can solve the problems of poor operating conditions and low processing efficiency, and achieves convenient operation, processing efficiency and output improvement. The effect of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

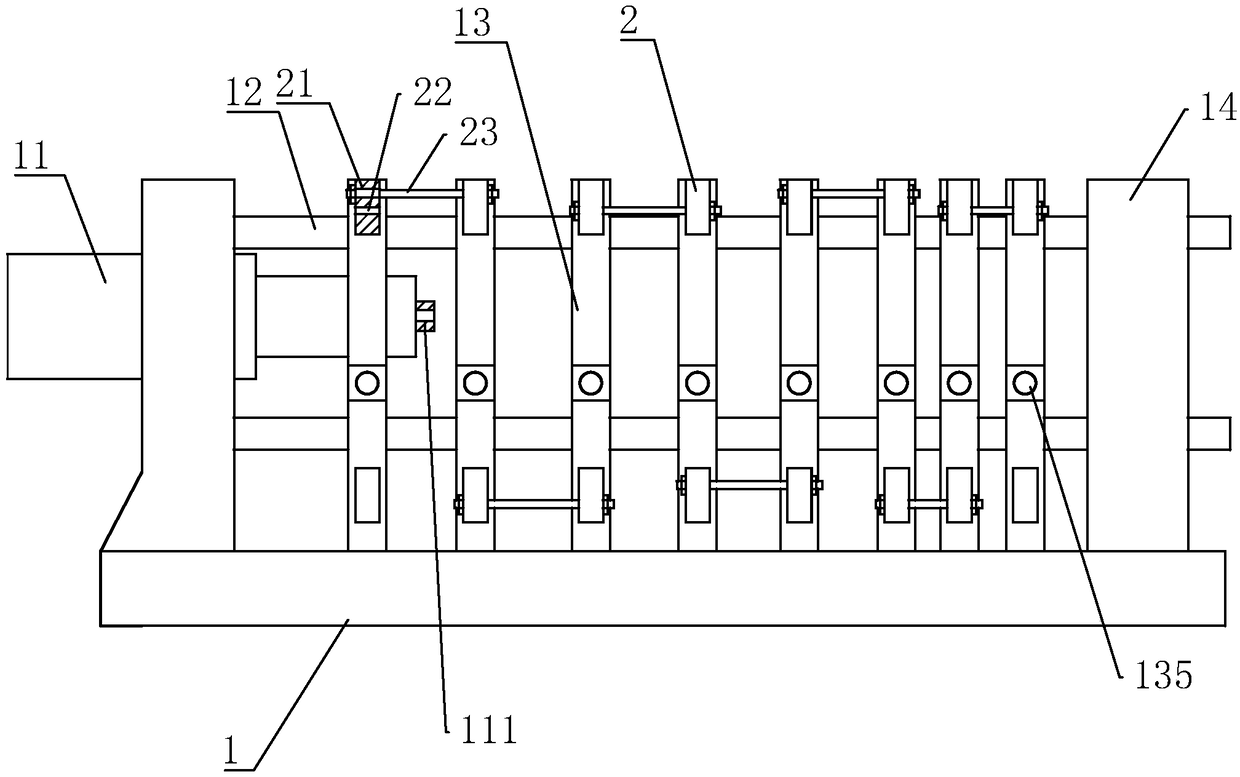

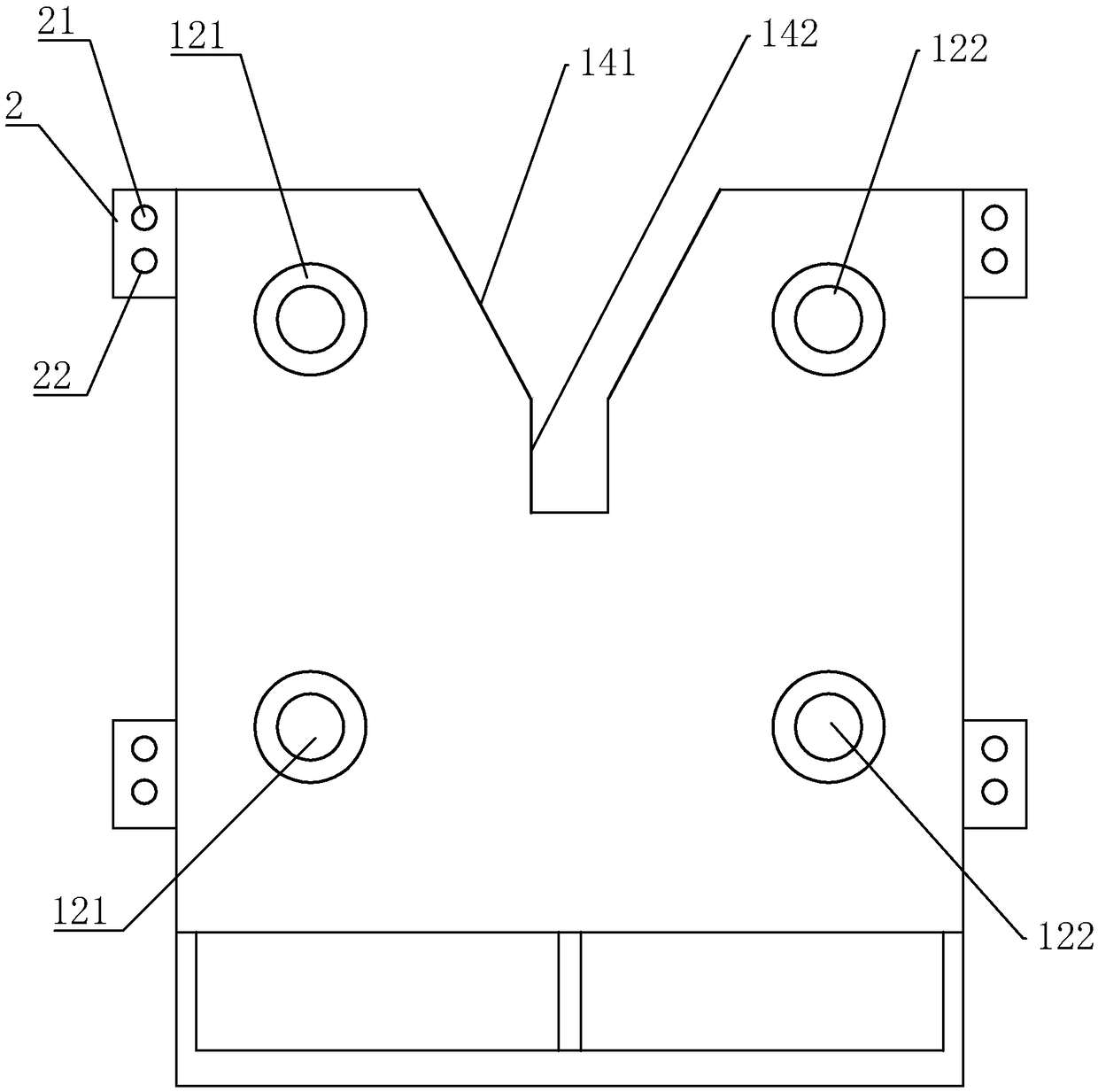

[0030] The present invention aims to provide a binding rod numerical control hydraulic high-speed flat forging machine, such as figure 1 As shown, it includes a base 1, and one end of the base 1 is provided with a horizontally placed main shaft hydraulic cylinder 11, and the main shaft hydraulic cylinder 11 is provided with guide rods 12 on both sides of its main shaft piston rod, and a mold body 13 is provided on the guide rod 12, The guide rod 12 is arranged coaxially with the main shaft piston rod, and the end of the base 1 away from the main shaft hydraulic cylinder 11 is provided with a support seat 14 for fixing the guide rod 12 .

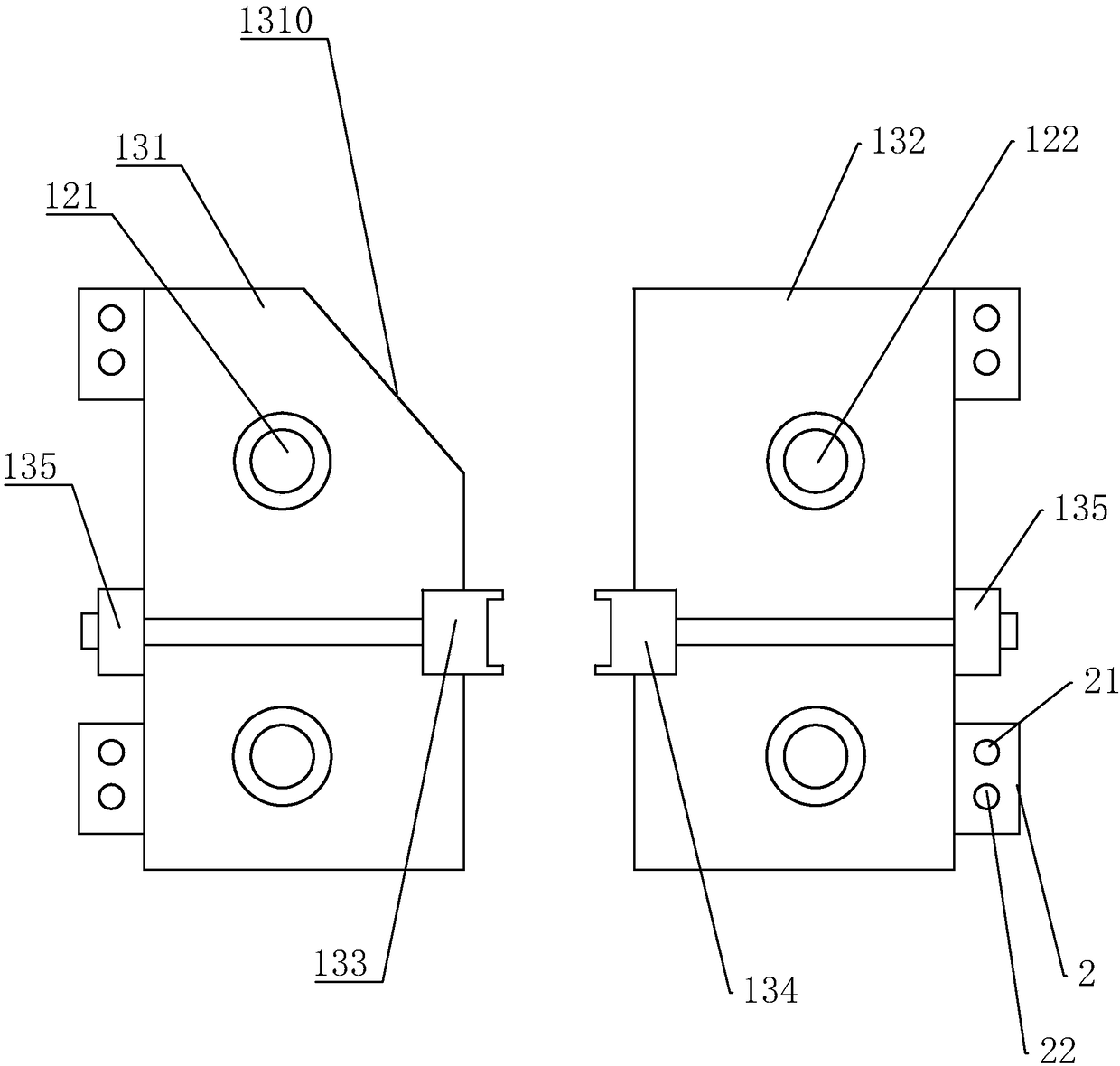

[0031] The guide rod 12 includes a pair of left guide rods 121 and a pair of right guide rods 122. The left guide rods 121 are jointly pierced with a number of left mold bodies 131, and the left mold body 131 is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com