Hard alloy mixing material vibration drying method and device

A cemented carbide and vibration drying technology, which is applied in the direction of drying solid materials, drying solid materials, heating to dry solid materials, etc., can solve the problems of difficult to control oxygen content, high chemical activity, pollution of the working environment, etc. The effect of avoiding powder and air contact, less equipment investment, and purifying the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A vibration drying method for cemented carbide mixture, which uses steam jacket heating to dry the cemented carbide mixture, the grinding medium is alcohol, the cemented carbide mixture is heated in a closed system under vacuum, and the gaseous grinding The medium is condensed into a liquid under vacuum. After the liquid alcohol becomes gaseous, it is sent to the condensing equipment through the pipeline to be condensed into liquid. The alcohol condensation process is carried out twice, and the second condensation is carried out after the first preliminary condensation.

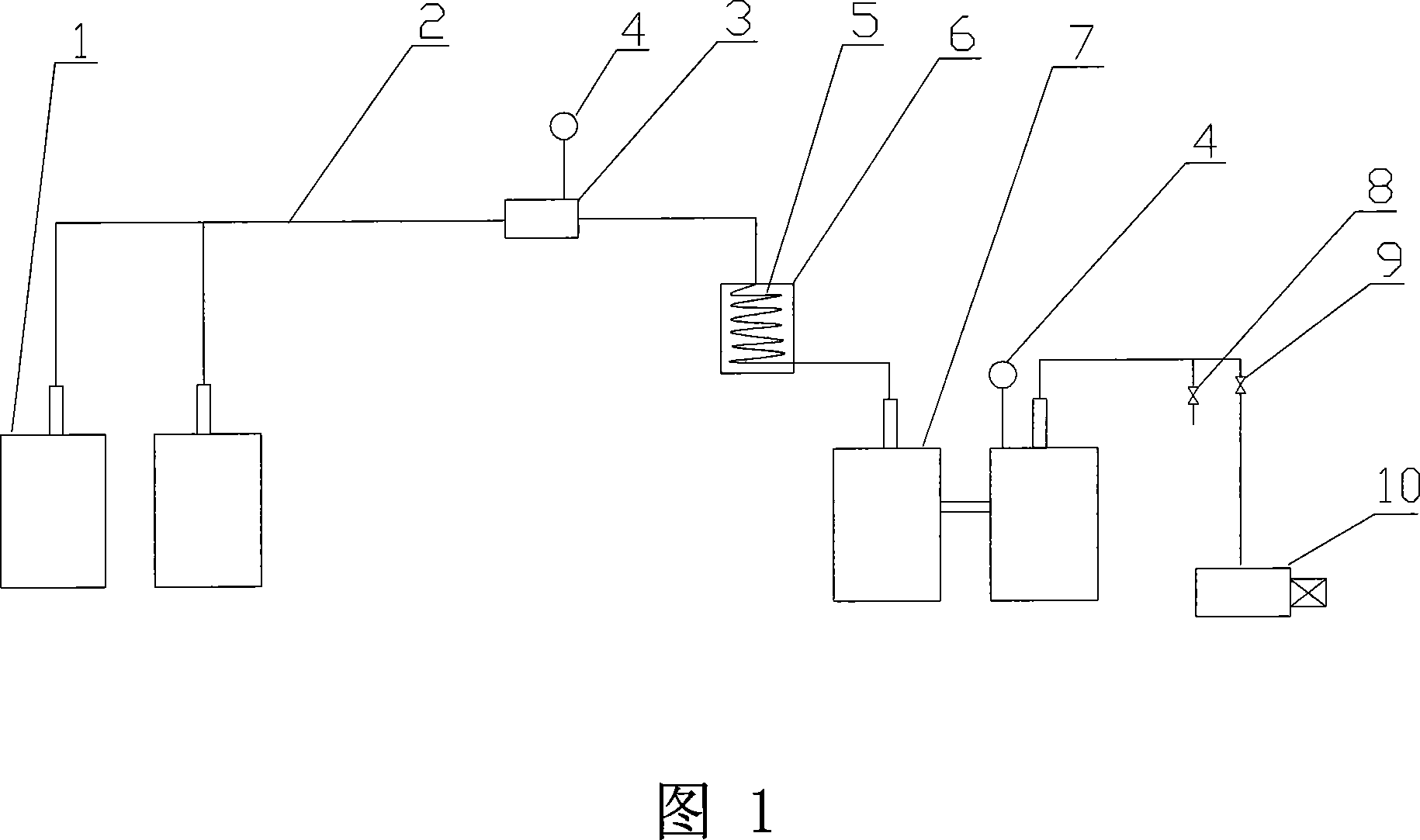

[0024] A vibratory drying device for cemented carbide mixture, which consists of a jacketed steam vibrating dryer 1, a vacuum pipeline 2, condensing equipment, a vacuum pump 10, and a recovery tank 7. The condensing equipment consists of a primary condenser 3 and a serpentine condensing Pipe 5 and cooling water tank 6 are composed of steam shaker 1, first-stage condenser 3, serpentine condenser pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com