Full-automatic bar flaw grinding system based on industrial robot

An industrial robot and fully automatic technology, which is applied in the direction of grinding machine parts, workpiece feed movement control, and machine tools designed for grinding workpiece rotating surfaces, etc., can solve the problems of uncontrollable grinding depth, human dust damage, repair Low grinding accuracy and other issues, to improve the accuracy of defect identification and grinding accuracy, purify the production environment, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further illustrated below in conjunction with the accompanying drawings and specific examples, and these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

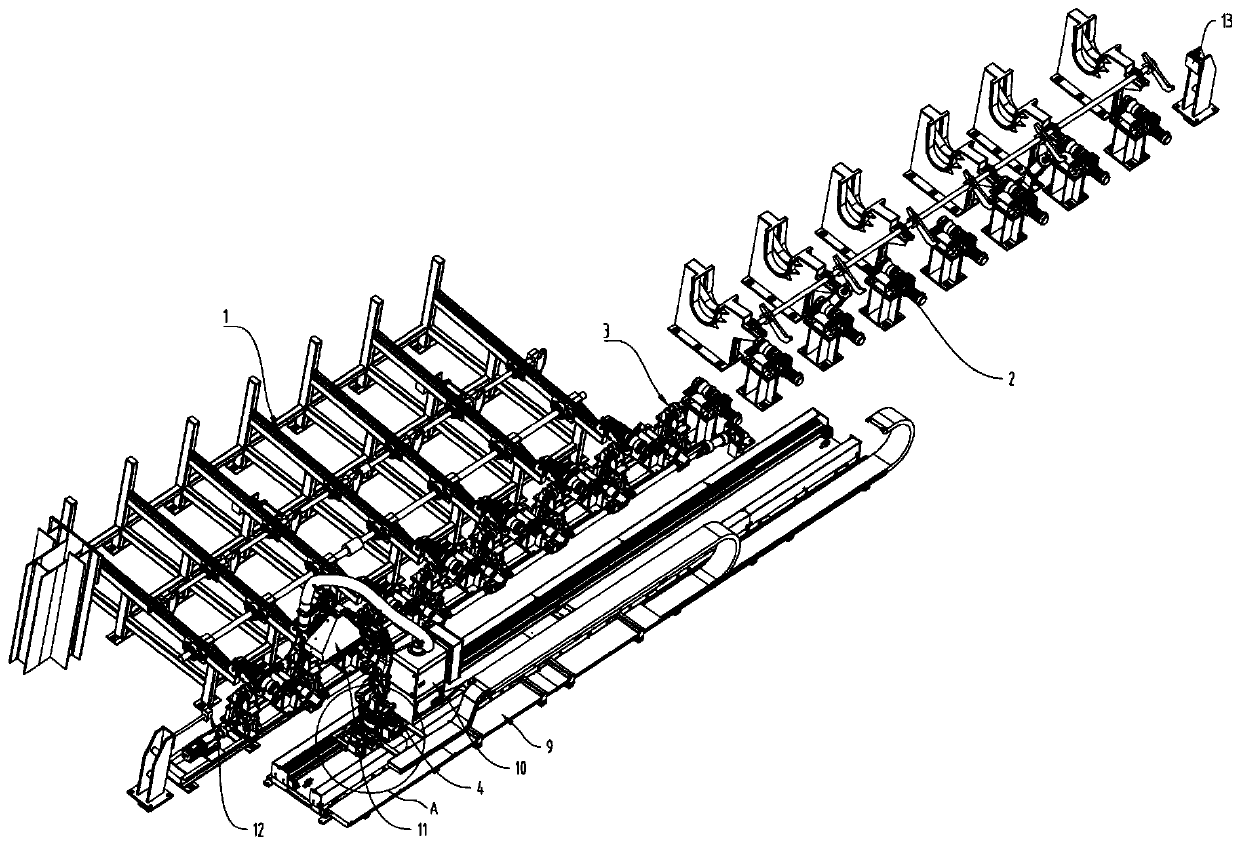

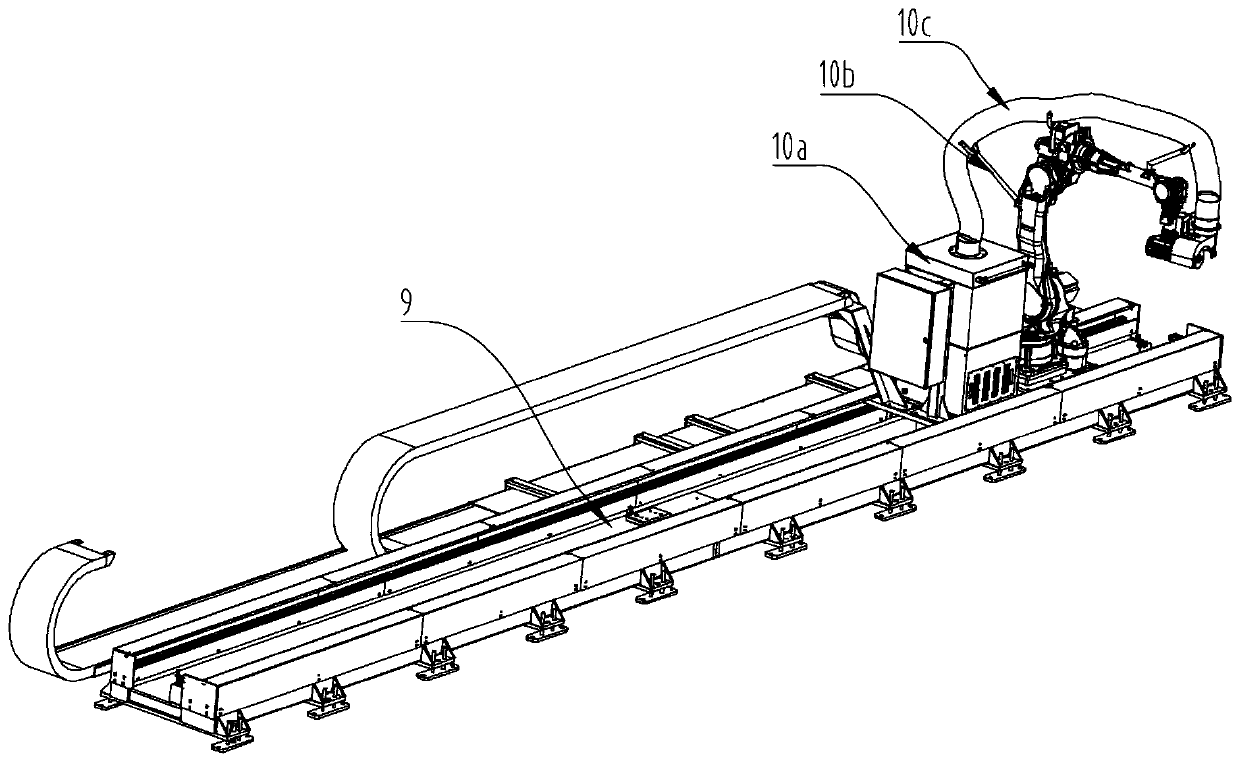

[0039] A fully automatic bar defect grinding system based on industrial robots, as attached figure 1 , 4 As shown, it includes loading device 1, unloading device 2, counter-rotating roller table 3, robot body 4, mounting flange 5, force-position actuator 6, floating grinding head 7, first servo motor 8, and sliding device 9 , Dust removal device 10, visual recognition device 11, left proximity sensor 12, right proximity sensor 13.

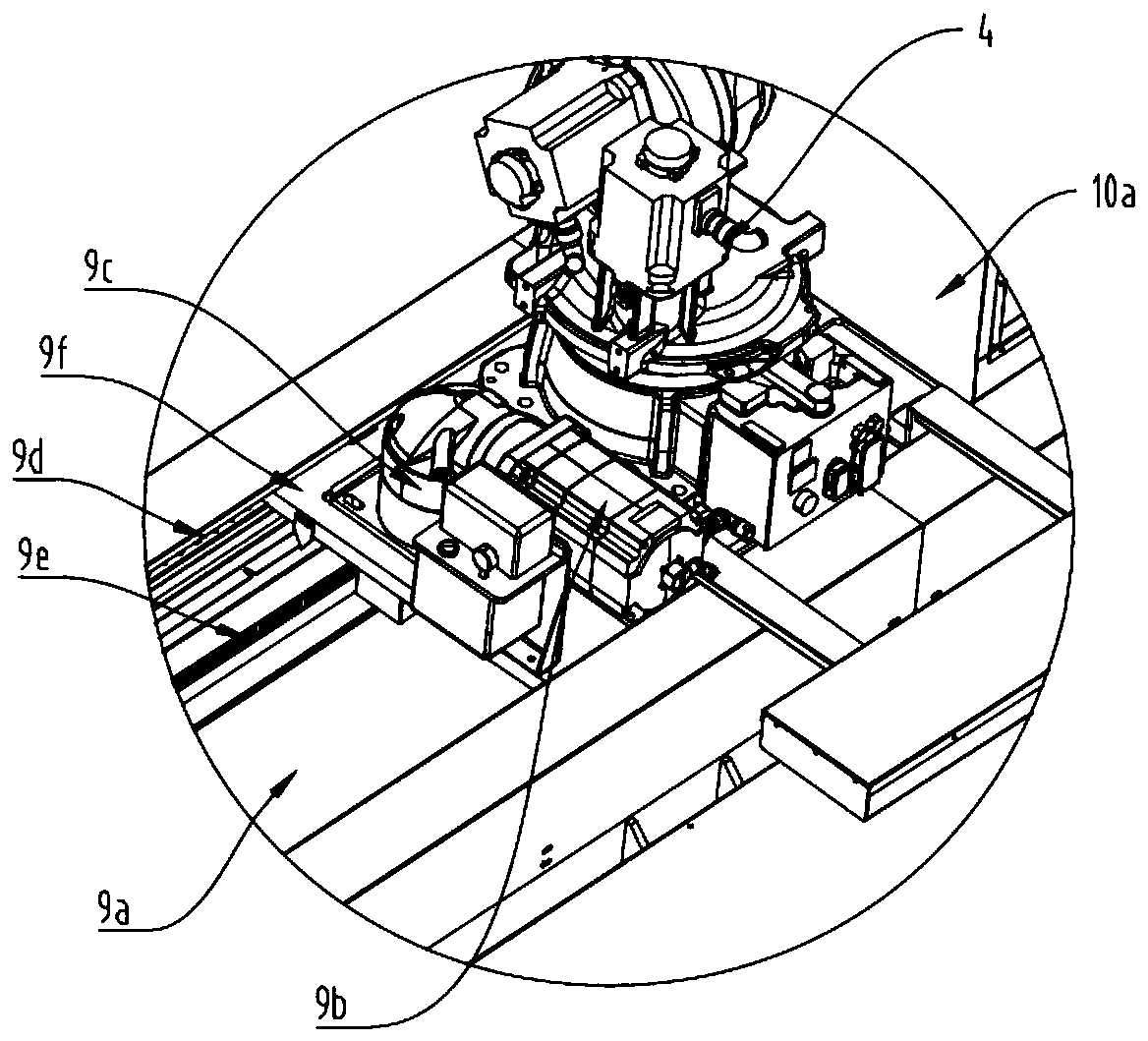

[0040] In order to realize floating grinding and precisely control the grinding track, in this embodiment, the integrated structure of the front end grinding of the robot body is shown in 4 and 6: the upper end of the force-position actuator 6 is connected to the robot body 4 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com