Crosshead shoe sealing shaft coupler

A cross-slide, coupling technology, applied in the direction of coupling, elastic coupling, engine sealing, etc., can solve the problem of reduced service life of the flap damper sealing device, safety production and production environment impact, wear and tear Parts can not be compensated and other problems, to ensure the pressure, improve the service life, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

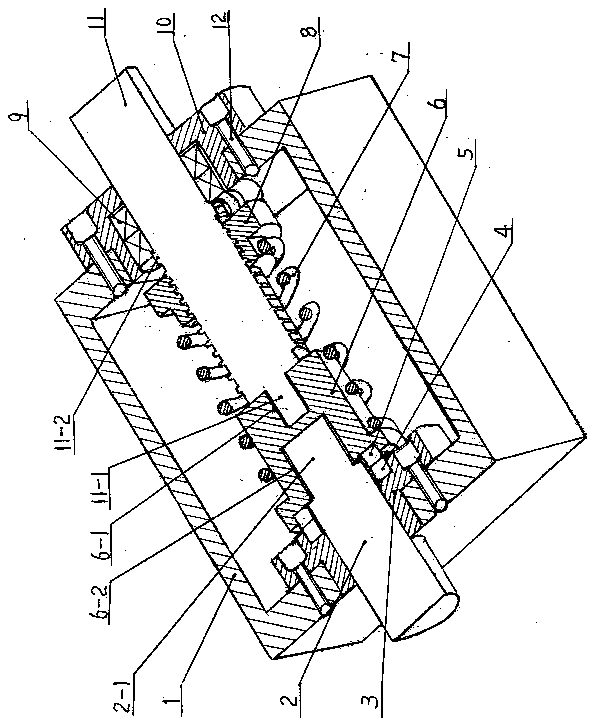

[0009] Examples, see attached figure 1 , the cross slider seal coupling is fixed with two connecting bolts 12 in the center hole of the left end of the housing 1, and the static sealing flange 3 is fixed, and the turning shaft 2 is movable in the static sealing flange 3, and the right end of the turning shaft 2 A flip shaft plug 2-1 is provided. In the center hole at the right end of the housing 1, a flange bearing seat 10 is fixed with two connecting bolts 12, and two sets of bearings 9 are arranged side by side in the flange bearing seat 10, and a swing rod is installed inside the flange bearing seat 10 and the bearing 9. The connecting shaft 11 is provided with a bearing limit boss 11-2 on the swing rod connecting shaft 11, and the bearing limit boss 11-2 is used for the axial limit of the bearing 9, and the swing rod connecting shaft 11 in the housing 1 Threaded connection is equipped with adjusting nut 8, and the left end of fork connecting shaft 11 is provided with fork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com