Efficient energy-saving type paint mixing device

An energy-saving, coating technology, applied in mixers with rotary stirring devices, transportation and packaging, dissolving and other directions, can solve problems such as safety, poor environmental protection, hidden safety hazards, and unenvironmental protection, and achieve improved stirring effects and purifying production. environment, the effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

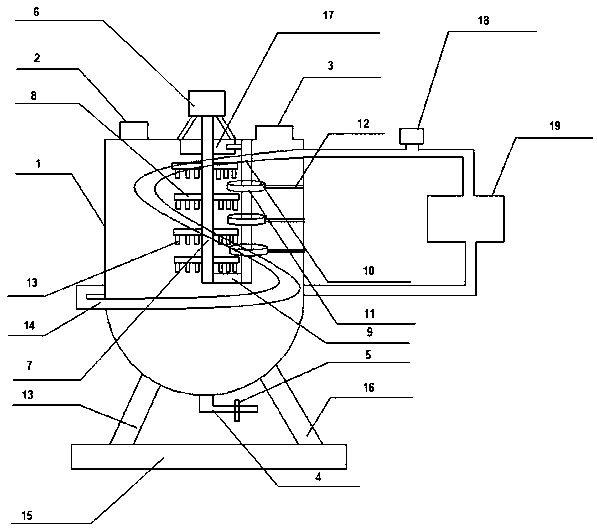

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0015] Such as figure 1 As shown, a high-efficiency and energy-saving paint mixing device includes a kettle body 1 and a stirring mechanism. The top surface of the kettle body 1 is provided with a feed port 2 and an air outlet 3, and the bottom surface of the kettle body 1 is protruding downward. The spherical shape and the lowest point are provided with a discharge port 4, and a valve 5 is provided at the discharge port 4. The stirring mechanism includes an explosion-proof motor 6 located on the top surface of the kettle body 1, and the output end of the explosion-proof motor 6 is connected to the rotating shaft 7 The upper end of the rotating shaft 7 extends into the kettle body 1, the surface of the rotating shaft 7 is respectively welded with a stirring rotating shaft 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com