A high-pressure cutting and punching device for glass

A punching device and cutting device technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of large processing errors, high labor intensity, glass breakage, etc., and achieve corrosion prevention, high degree of automation, and short circuit prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

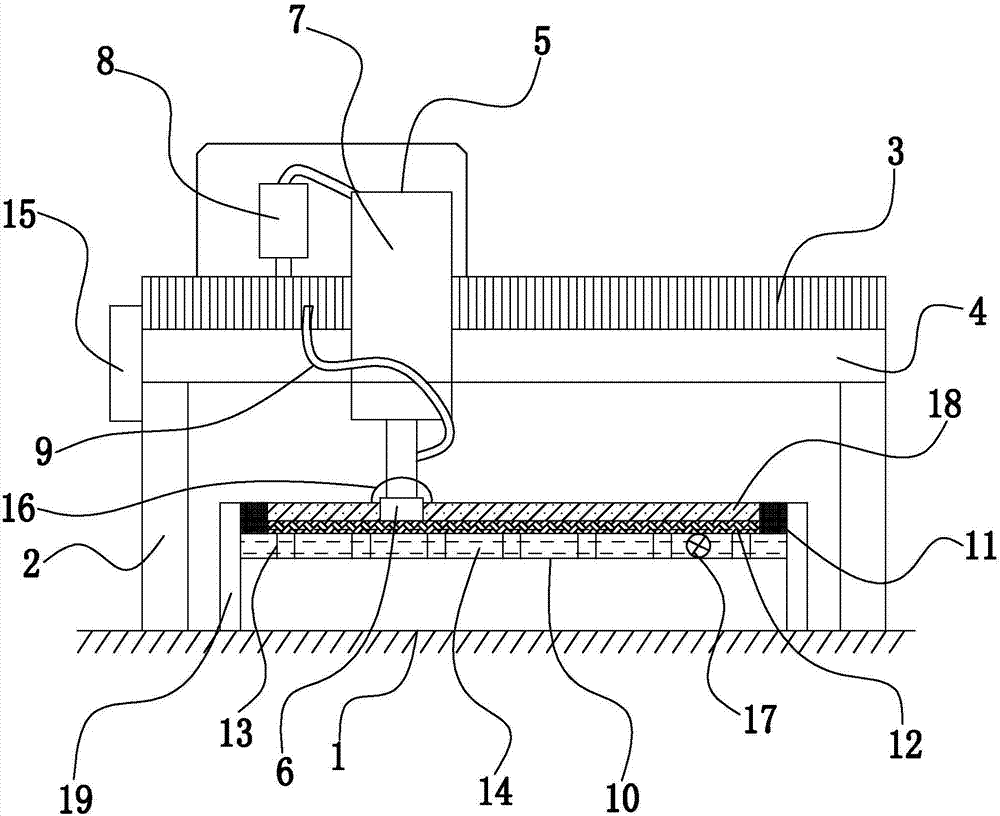

[0017] Example: such as figure 1 As shown, a high-pressure cutting and punching device for glass includes two support columns 2 arranged at both ends of a horizontal base 1. The upper ends of the two support columns 2 are connected to a crossbeam 3, and the crossbeam 3 is provided with a slideway 4 and a cutting device 5, the cutting device 5 slides along the length direction of the slideway 4, and the cutting device 5 is controlled by a controller 15 through a circuit; 19 are fixedly connected; the cutting device 5 includes a drill bit 6, a pressurizing device 8 and a drill bit lifting cylinder 7 for driving the drill bit 6 to feed; the pressurizing device 8 is connected with the drill bit 6 through a pressure pipe 9, so that the drill bit 6 is rapidly advanced ; The trajectory of the drill bit 6 corresponds to the length of the liquid tank 10, and the pressurizing device 8 is a hydraulic damper device. It adopts drill bit lifting cylinder 7 and pressurizing device 8 to run ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com