Chemical dust removal device

A technology of dust removal device and chemical industry, applied in separation devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of increasing equipment cost and occupied space, unable to guarantee dust removal and purification effect, volatilization and other problems, so as to avoid adhesion of particulate matter , The effect of improving cleaning ability and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

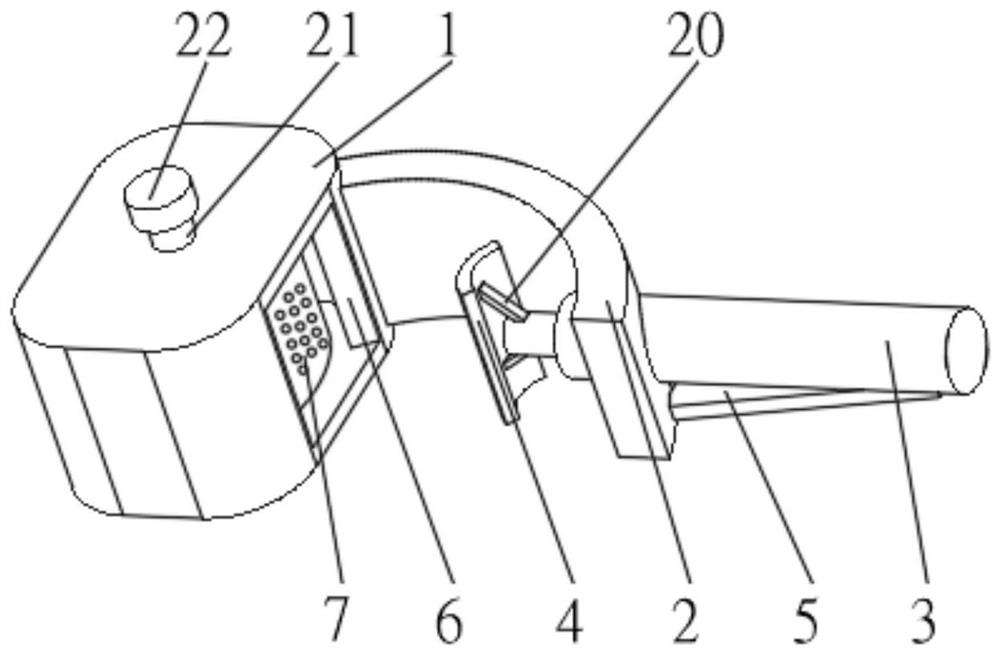

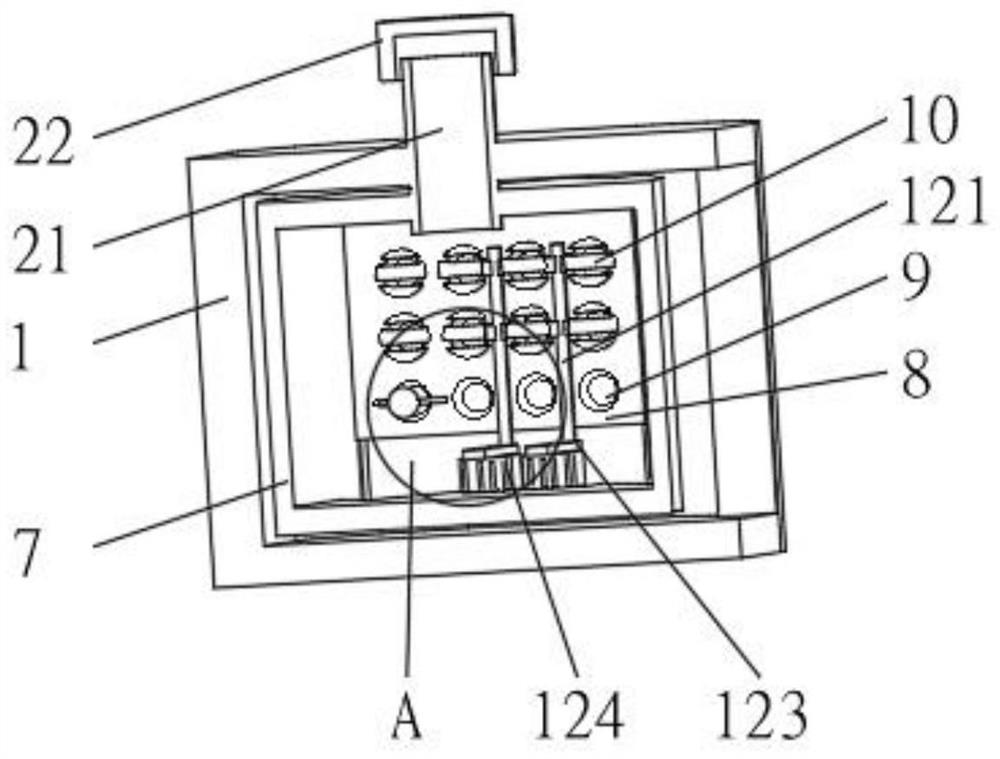

[0029] see Figure 1-5 , the present invention provides a technical solution: a chemical dust removal device, including a storage frame 1, one side of the storage frame 1 is fixedly connected with an extension plate 2, and the end of the extension plate 2 away from the storage frame 1 is equipped with an electronically controlled telescopic rod 3, The output end of the electronically controlled telescopic rod 3 runs through the extension plate 2 and is fixedly connected with the extrusion plate 4. The side of the storage frame 1 close to the extension plate 2 is provided with a spray hole 6, and a liquid storage bag 7 is installed inside the storage frame 1. One side of the liquid bag 7 is evenly provided with injection holes, and a limiting plate 8 is installed symmetrically between both sides of the inner wall of the liquid storage bag 7, and a flow port 9 is evenly opened on one side of the limiting plate 8, and a flow port 9 is installed on one side of the liquid bag 7. Th...

Embodiment 2

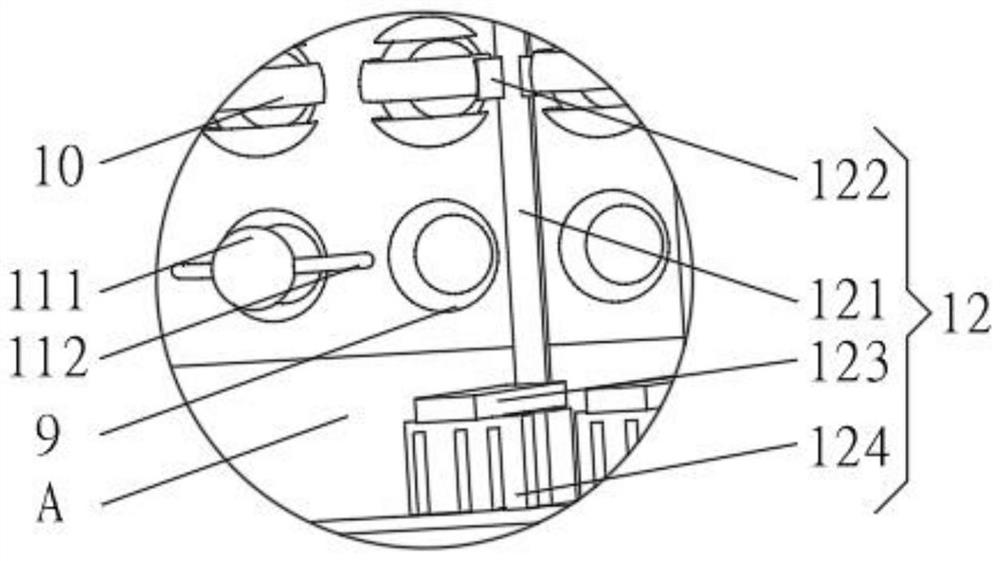

[0035] see Figure 1-5, the present invention provides a technical solution: on the basis of Embodiment 1, a cleaning device 12 is installed on one side of the limiting plate 8 between the two sides of the circulation port 9, and the cleaning device 12 includes a conductive strip 121, which conducts Both sides of the strip 121 are fixedly connected to the intercepting half-frame 10 through the conduction sheet 122, and a mounting plate 123 is fixedly connected between the two sides of the conduction strip 121, and the bottom of the mounting plate 123 is evenly equipped with a cleaning head 124, and the cleaning head 124 The bottom of the bottom is slidably connected with the liquid storage bag 7.

[0036] During use, the retrieving ball 111 hits and intercepts the half-frame 10 to produce a vibration, which is transmitted to the cleaning head 124 through the conductive sheet 122 and the conductive strip 121, driving the cleaning head 124 to vibrate and rub against the inner wa...

Embodiment 3

[0038] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, the side of the retrieving ball 111 close to the intercepting half-frame 10 is rotatably connected with an opening and closing plate 113, and the side of the opening and closing plate 113 away from the retrieving ball 111 is fixedly connected with a Reclaiming shovel 114, reclaiming shovel 114 is slidably connected with interception half-frame 10.

[0039] The outside of the retrieving ball 111 is provided with a receiving groove 13, and the opening and closing plate 113 is installed in the inside of the receiving groove 13;

[0040] The top of the reaction block 17 is provided with a guide groove 18, and the inner top of the filling groove 16 is fixedly connected with a guide plate 19, which extends to the inside of the guide groove 18, and the guide plate 19 is a metal plate.

[0041] When in use, after the liquid storage bag 7 is squeezed, the internal water flow dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com