Anti-smudginess inserted vortex shedding flowmeter

A vortex flowmeter, plug-in technology, applied in the direction of volume measurement, liquid/fluid solid measurement, volume/mass flow generated by mechanical effects, etc., can solve the problems affecting the working efficiency of the flowmeter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

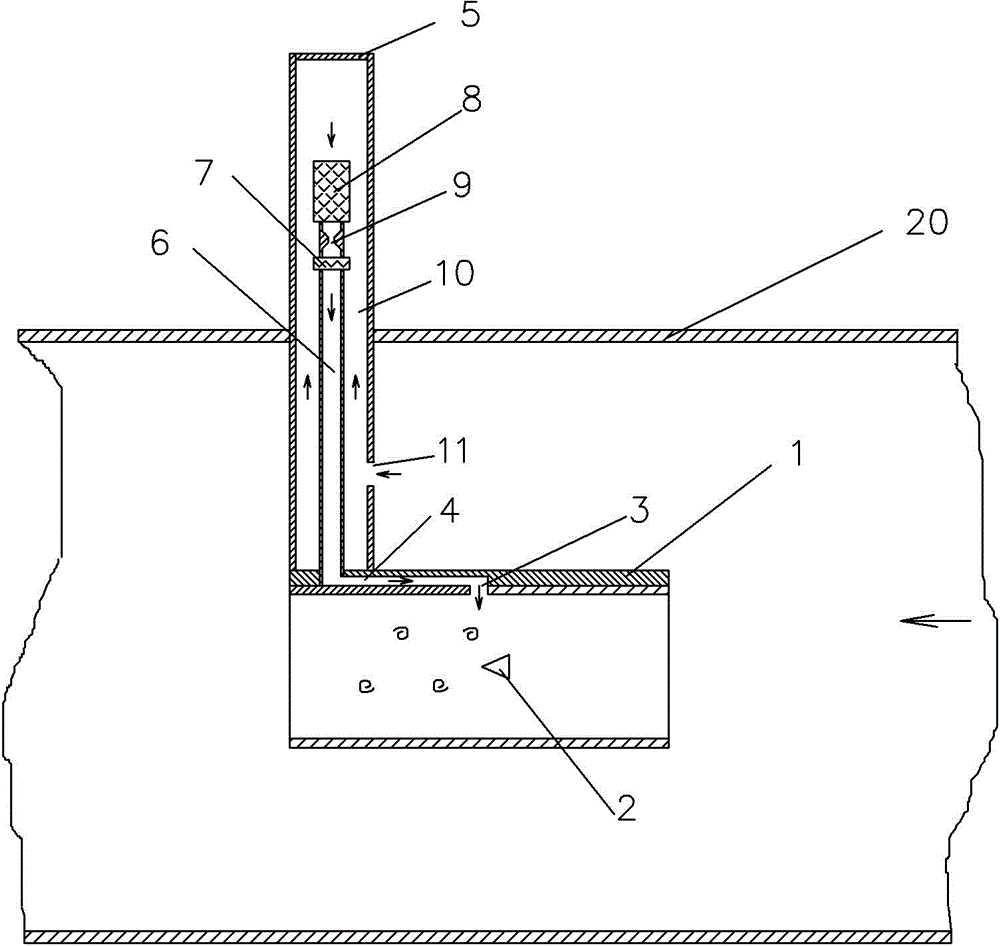

[0019] Such as figure 1 As shown, an embodiment of an anti-dirty plug-in vortex flowmeter, the vortex flowmeter in this embodiment includes a cylindrical measuring head 1 with fluid passages open at both ends, in the middle of the measuring head 1 A vortex generating body 2 with a small end facing the rear of the measuring head is fixed at the axis, and a pressure tapping port 3 is opened on the inner wall of the corresponding vortex generating body of the measuring head 1 . The measuring head 1 is fixed with an inner conduit 6 extending radially upwards above the measuring head, the central axis of the inner conduit 6 is perpendicular to the central axis of the vortex generating body 2, and the inner conduit 6 is located on the measuring head 1 At the rear of the pressure tapping port 3, the measuring head 1 is provided with a connecting channel 4 that communicates with the inner conduit 6 and the pressure tapping port 3 and is located behind the pressure tapping port. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com