The control method for starting the cold tandem mill regardless of the small coils

A technology of cold tandem rolling unit and control method, which is applied in the direction of rolling mill control device, metal rolling, roll speed control, etc. It can solve the problems of reducing the utilization factor of rolling mill speed, poor export steel coil ladle, and affecting the production capacity of the unit, and achieves Reduce cold rolling waste, maintain stable coil shape, and improve factory logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

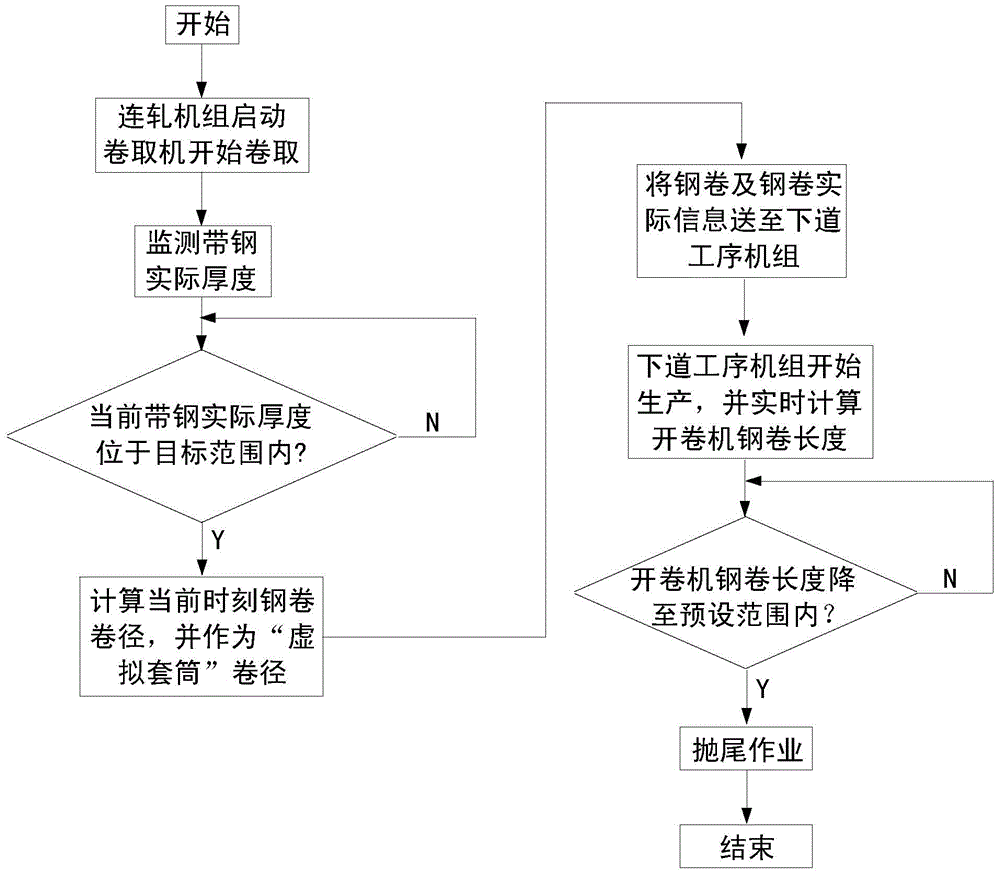

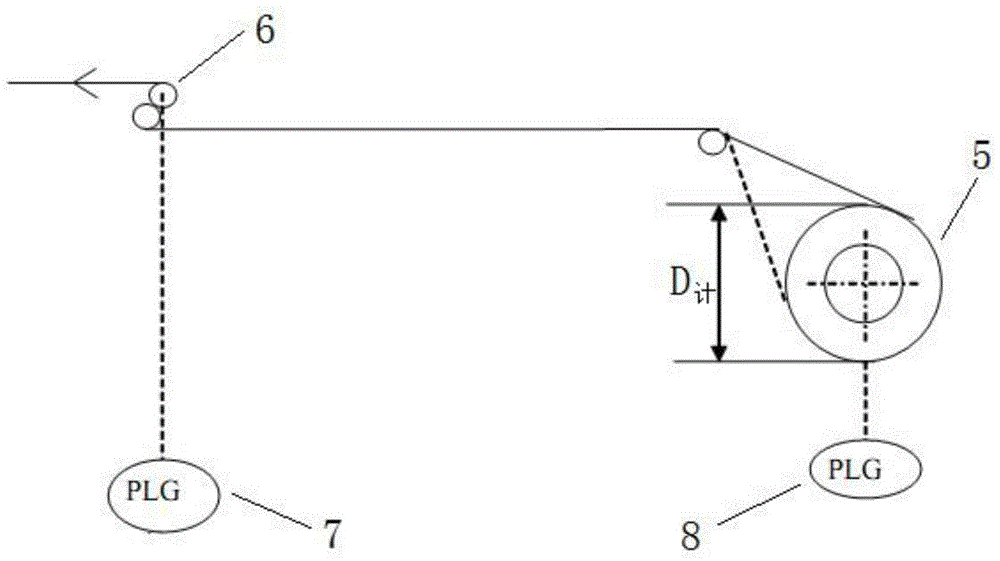

[0032] like figure 1 As shown, the cold tandem rolling mill in this embodiment starts the control method regardless of small coils, including the following steps:

[0033] In the first step, the cold tandem rolling unit starts and starts rolling strip steel, and the coiler starts to coil the export strip; the coiler is located at the exit of the cold tandem rolling unit; go to the second step;

[0034] The second step is to continuously monitor the actual thickness of the exit strip by using a thickness gauge located at the exit of the cold tandem rolling mill; when the actual thickness is within the preset thickness range, go to the third step;

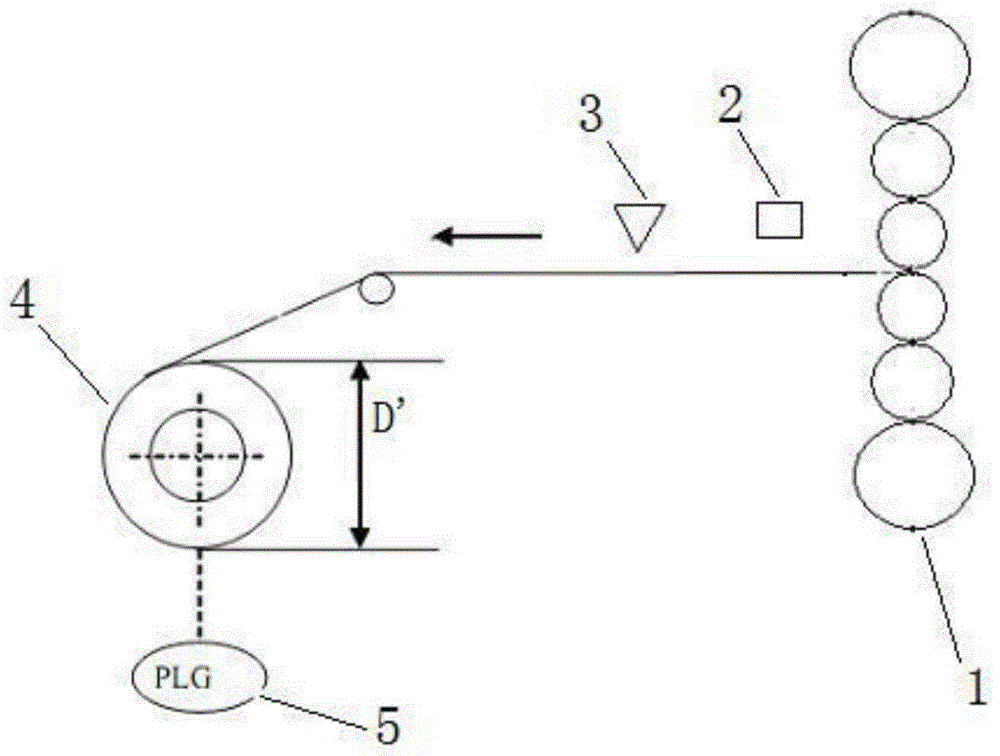

[0035] The third step is to calculate the coil diameter of the coil on the coiler at the current moment according to the current exit strip line speed V and the coiler motor speed N, and use this coil diameter as the "virtual sleeve" coil diameter D 0 ;Roll diameter of "virtual sleeve" D. 0 The unit of N is mm, the unit of N is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com