Lubricating structure for transmission mechanism

A technology for lubricating structures and transmission mechanisms, applied to transmission parts, gear lubrication/cooling, mechanical equipment, etc., which can solve problems such as secondary wear, poor lubrication effect, and inability to discharge metal debris, so as to avoid secondary wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

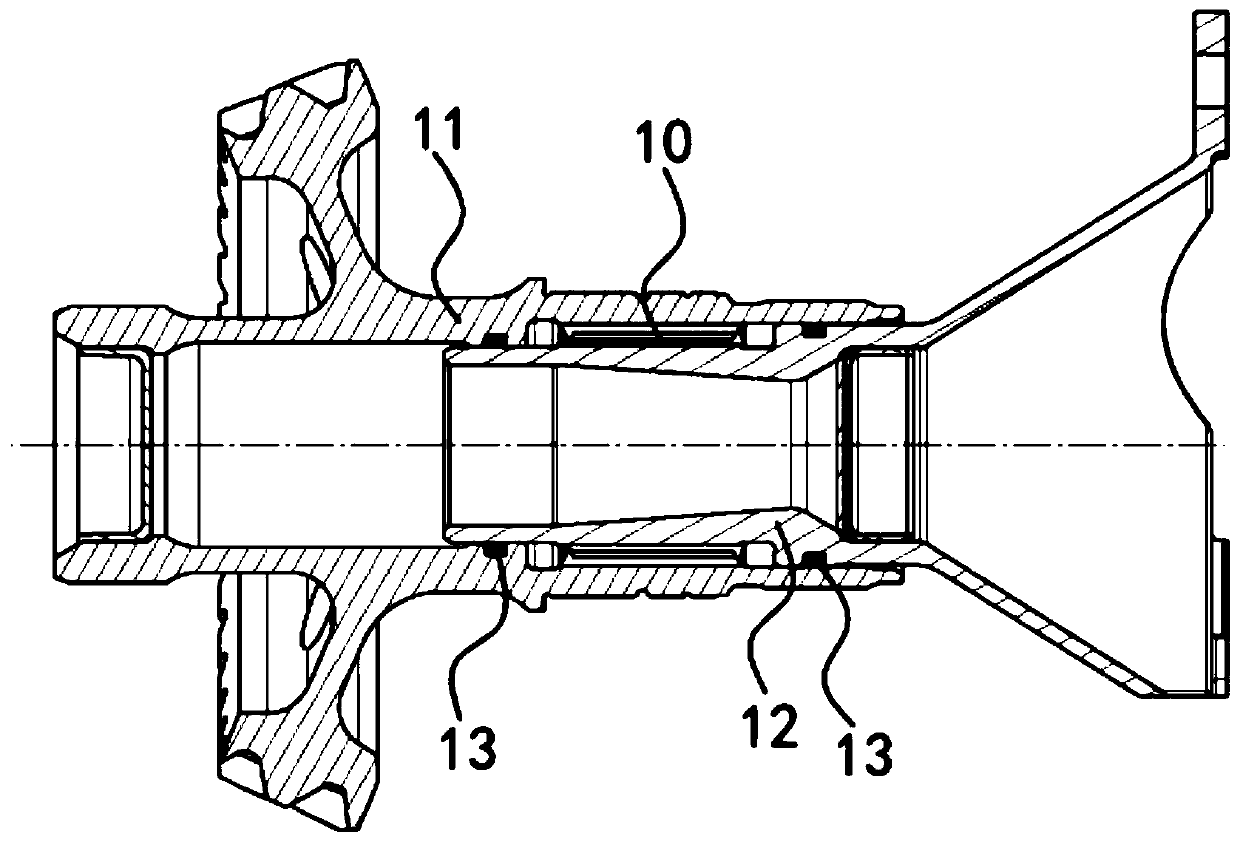

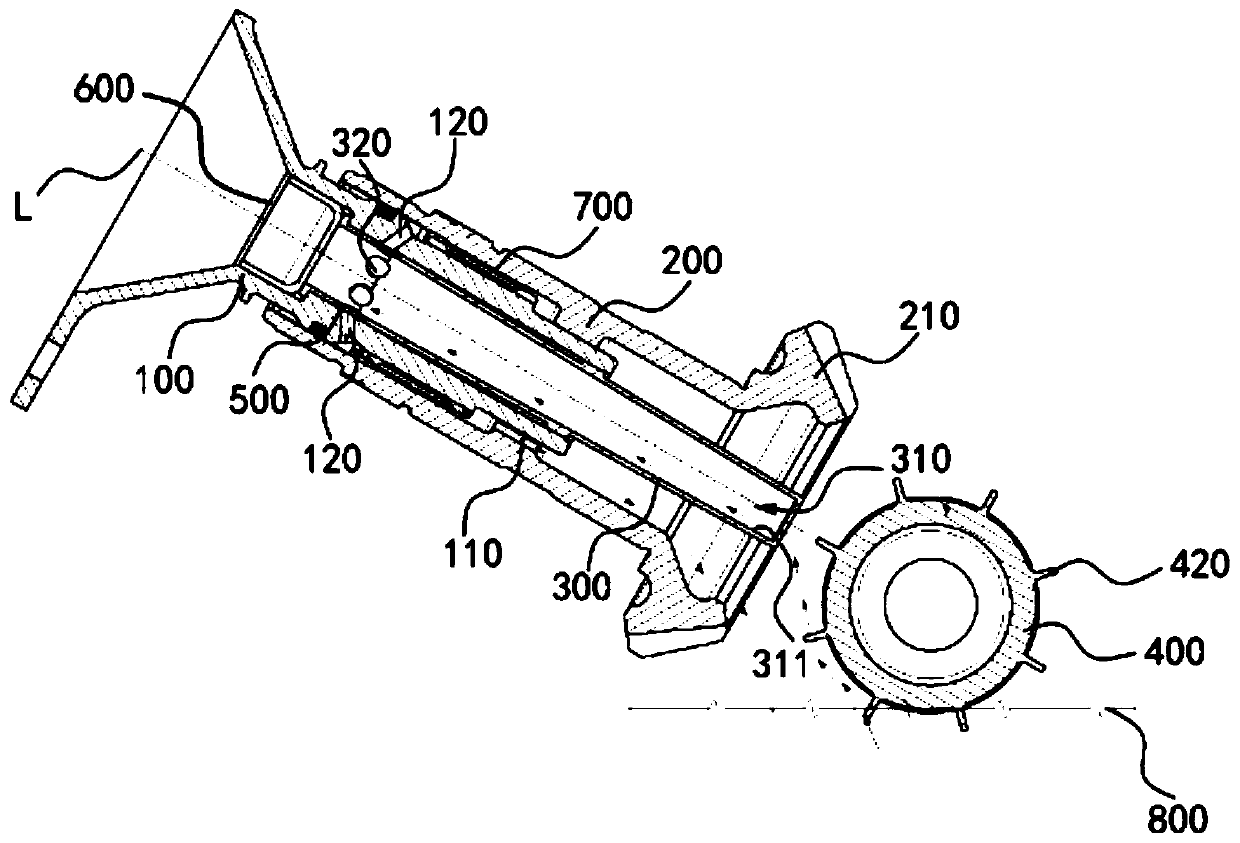

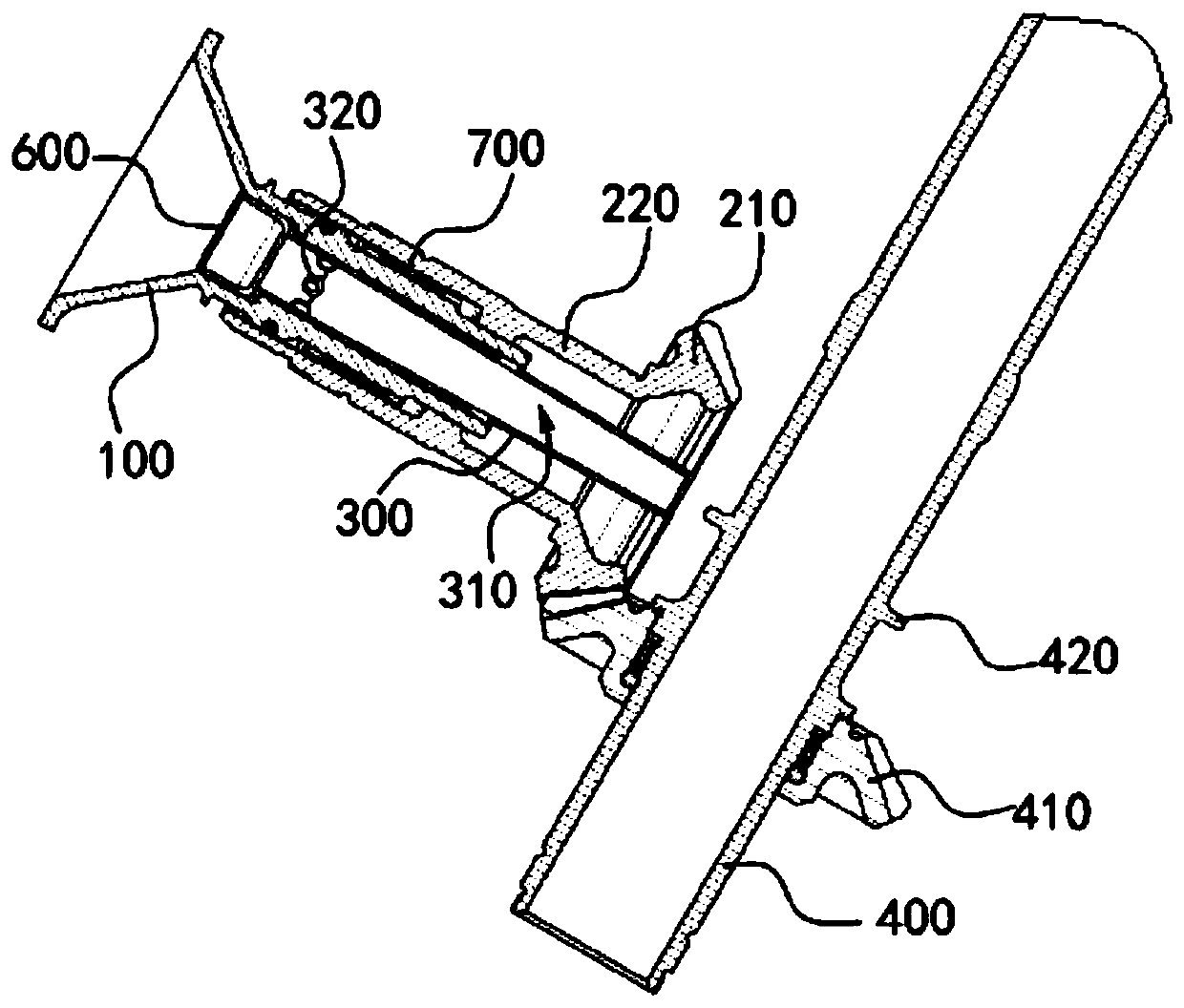

[0048] Such as figure 2 and image 3 as shown, figure 2 is a schematic diagram of a lubrication structure of a transmission mechanism shown according to an exemplary embodiment. image 3 It is a schematic diagram of another perspective of the lubricating structure of the transmission mechanism shown according to an exemplary embodiment. In an exemplary embodiment, the transmission mechanism includes an input shaft 100 , an output shaft 200 and a rotating shaft 400 , the input shaft 100 is linked to the output shaft 200 , and the output shaft 200 is linked to the rotating shaft 400 .

[0049] Such as figure 2 and image 3As shown, in some embodiments, both the input shaft 100 and the output shaft 200 are hollow structures, and the output shaft 200 is sleeved outside the input shaft 100, between the inner side wall of the output shaft 200 and the outer side wall of the input shaft 100 A keyed connection, such as a spline pair 700 , is formed to transmit power from the in...

Embodiment 2

[0060] In some embodiments, the in-out relationship of the input and output shafts can be reversed. Specifically, the input shaft can be sheathed outside the output shaft, and the rotating shaft can be linked to the input shaft or the output shaft. The oil collecting tube is fixedly connected to the inside of the output shaft, and other structures and beneficial effects are basically the same as those of the first embodiment above, and will not be repeated here.

Embodiment 3

[0062] An embodiment of the present invention provides a lubrication structure for a transmission mechanism. The transmission mechanism of this embodiment includes an input shaft, an output shaft and a rotating shaft. The output shaft is sleeved outside the input shaft, and the input shaft and the output shaft are connected by a key. , the rotating shaft is linked to the input shaft or output shaft. The structures and connections of the input shaft, the output shaft and the rotating shaft are basically the same as those of the first and second embodiments above, and will not be repeated here. The difference between embodiment three and above embodiment one and embodiment two is:

[0063] The lubricating structure of this embodiment includes an oil inlet channel, an oil return channel, and a plurality of first oil holes. The oil inlet channel is formed inside the input shaft and runs through the end face of the input shaft, so that the oil is thrown off by the oil rejection str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com