Noise reducing and anti-freezing device outside power plant cooling tower

An antifreeze device and cooling tower technology, which is applied to water shower coolers, sound-generating devices, instruments, etc., can solve the problems that affect the safe and normal operation of cooling towers, consume a large amount of sound-absorbing and noise-reducing panels, and fail to achieve noise-reducing effects, and achieve Ideal noise reduction effect, increased sound-absorbing area, and reduced ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

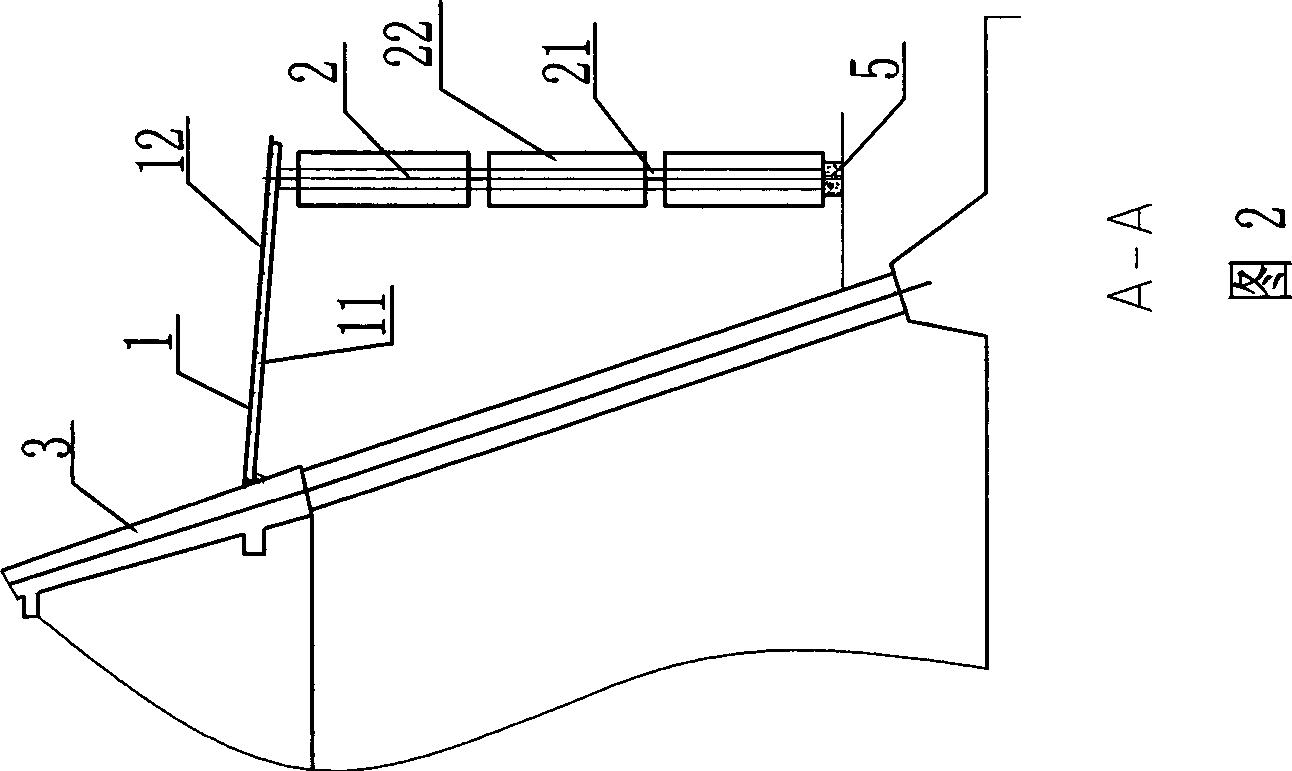

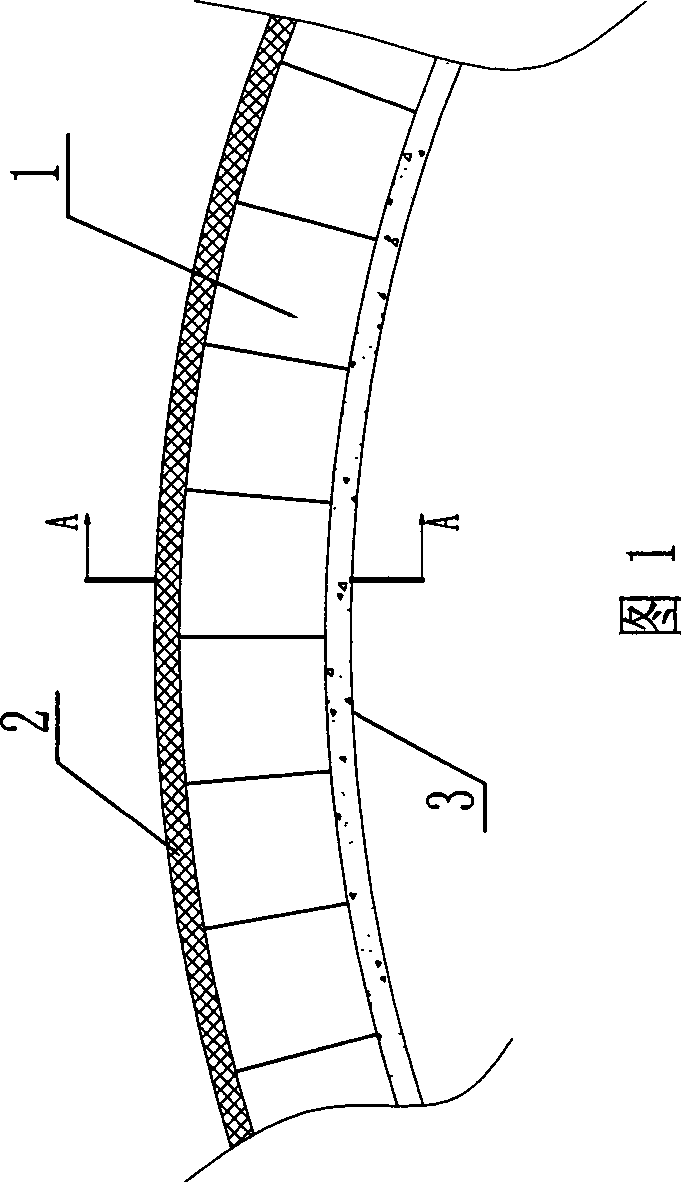

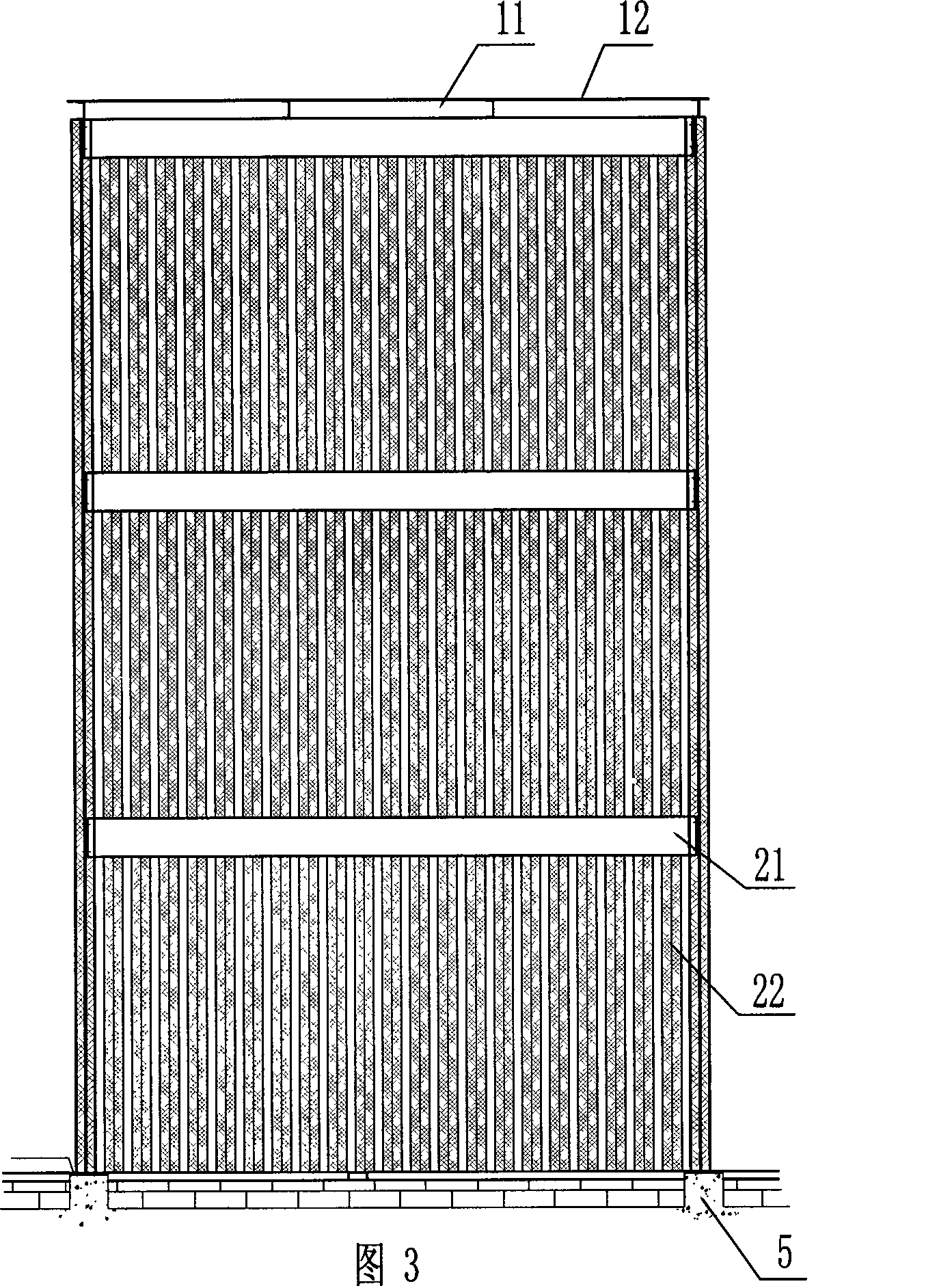

[0023] Example 1: The external noise reduction and antifreeze device of the cooling tower, as shown in Figures 1 and 2, includes a top sound blocking component 1 and a facade noise reduction and antifreezing component 2. The top sound blocking component 1 consists of a top surface. The frame 11 is composed of a waterproof partition 12. The facade noise reduction and antifreeze assembly 2 includes a three-speed facade frame 21 welded by I-beams and a number of sound-absorbing and noise-reducing panels 22. The inner end of the top frame 11 is fixed in the cooling system. The upper end of the air inlet of the tower 3, the outer end of the top frame 11 is fixed on the vertical frame 21, the lower end of the vertical frame 21 is fixed on the precast concrete base 5 on the ground, and the waterproof partition 12 is fixed on the top frame. 11; all sound-absorbing and noise-reducing panels 22 are divided into three groups and installed on the facade frame 21 at intervals, and there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com