Nonmetal composite air pipe construction process

A technology of composite air duct and construction technology, which is applied in the direction of pipeline layout, etc., can solve the problems of unstable quality of inorganic FRP air duct, large unit weight of air duct, high air leakage rate of air duct, etc., and achieve shortened construction period, small wind resistance and easy maintenance Easy care effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

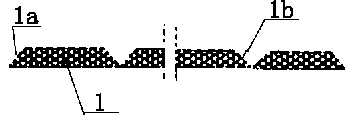

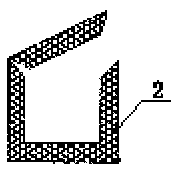

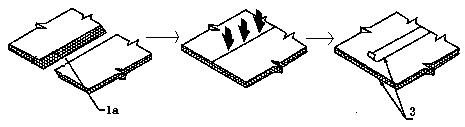

[0038] like Figure 1-10 As shown, the non-metallic composite air duct construction technique of the present invention comprises the steps:

[0039] 1) Preparation before construction: Prepare the required boards and tools. The boards of the present invention include boards made of glass magnesium, polyurethane, phenolic or glass fiber materials; the tools used include cutting machines, etc.;

[0040] 2) Paneling and cutting of air ducts: According to the size of the air ducts in the design drawings, the material and size of the panels actually used to make the ducts, determine the panels’ assembly and cutting methods, and then carry out batch panel blanking and Cutting, when the size of the actual air duct sheet is smaller than the size of the air duct in the design drawing, the sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com