Edge-locking type tubular belt conveyer

A tubular belt and conveyor technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low running resistance and low system energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

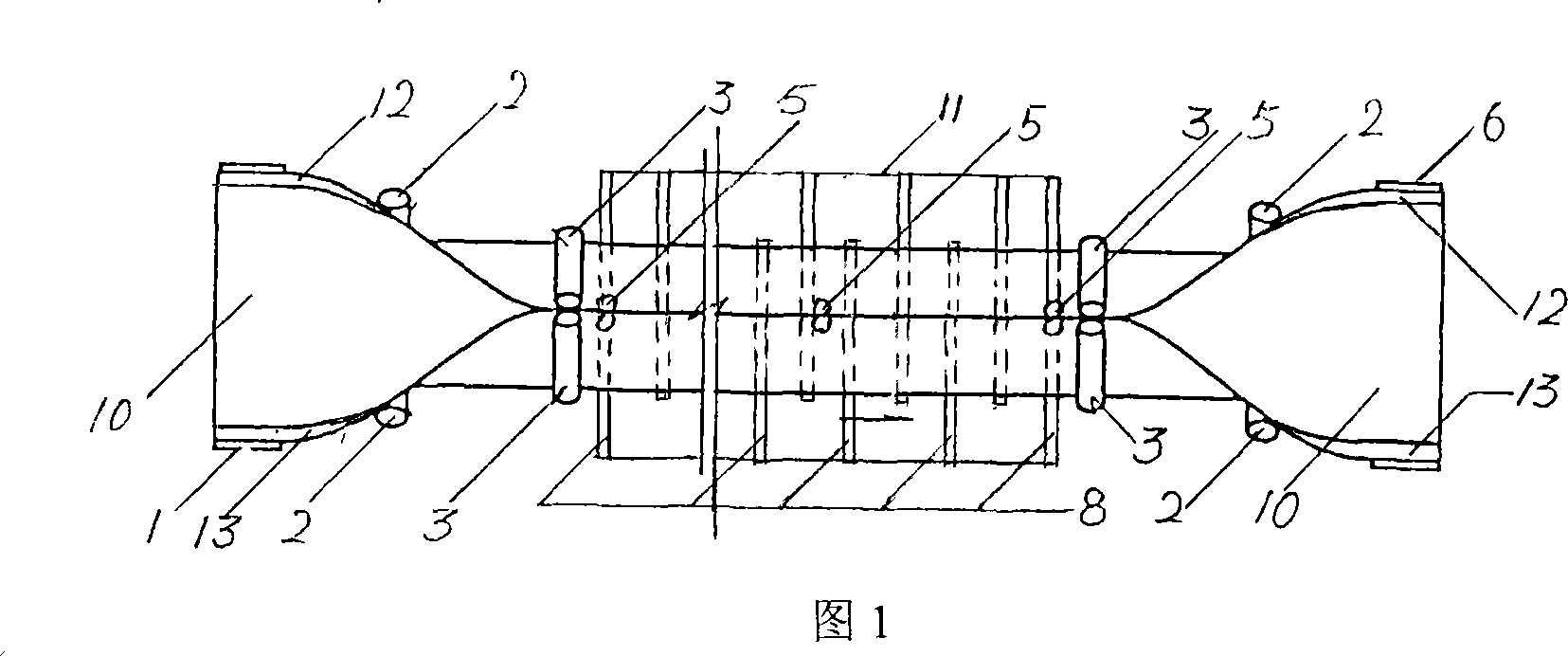

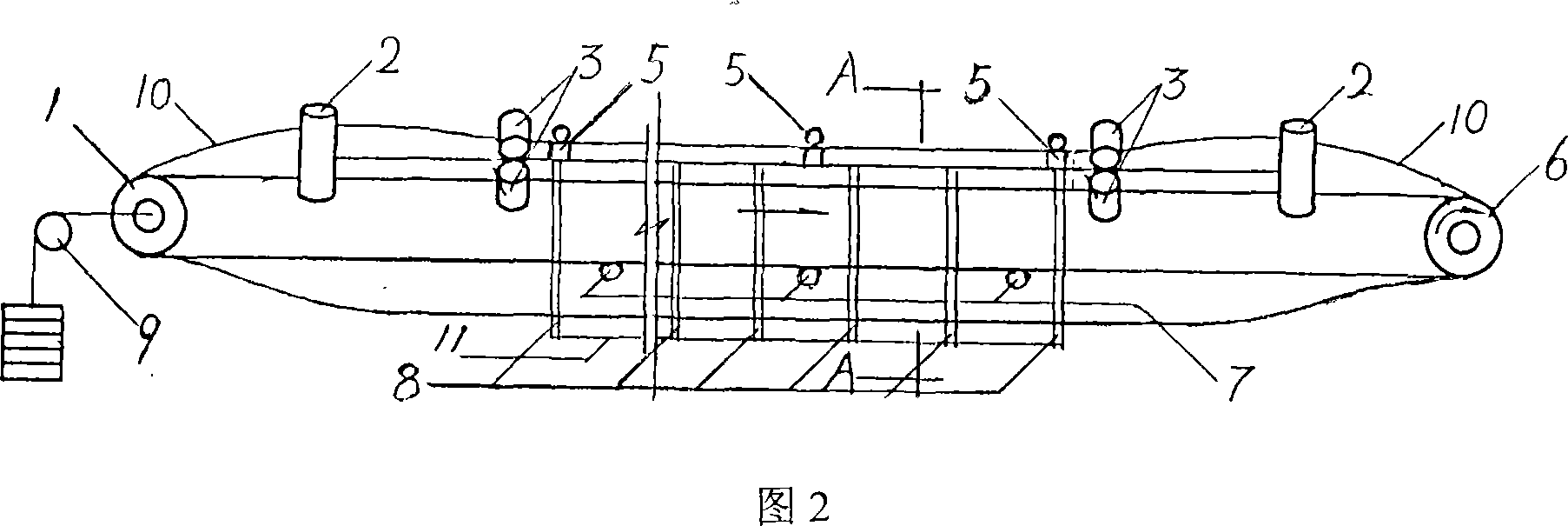

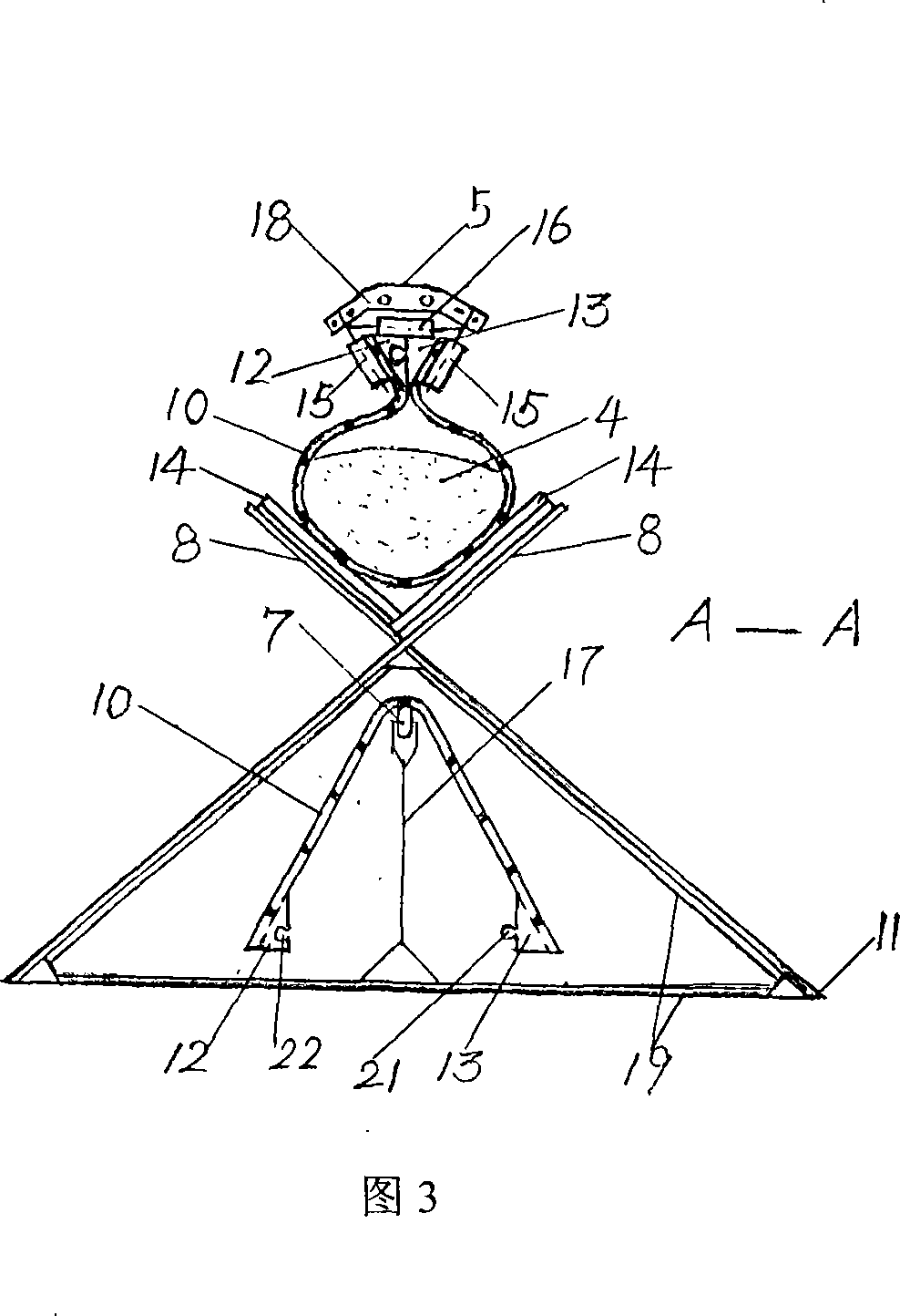

[0027] Below in conjunction with accompanying drawing, the present invention and concrete implementation will be further described:

[0028] Referring to the accompanying drawings, the drive drum (6) and the tail drum (1) are covered with an expanded endless conveyor belt (10), the conveyor belt (10) is tensioned by the tensioning device (9), and the driving device is connected to the drive drum (6). ) is driven to realize the circular rotation of the conveyor belt (10), the material (4) is wrapped in the tube-shaped conveyor belt (10) in the bearing section, and the wrapping and unwrapping are started by the guide roller (2) and the tube support Roller (3) realizes.

[0029] After the material is wrapped, the pipe seam rolled into the conveying pipe is formed by the upper male and female rails (21, 22) of the male and female strips (13, 12) of the zipper that are consolidated on the two sides of the conveyor belt (10). Locking to achieve the purpose of connection, the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com