Redundant drive three-freedom-degree parallel mechanism with double motion platforms

A technology of motion platform and degree of freedom, which is applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of ball joints, increase the difficulty of manufacturing, and difficult control of precision, so as to improve the rigidity and carrying capacity and facilitate manufacturing Simple effect of installation and kinematic model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

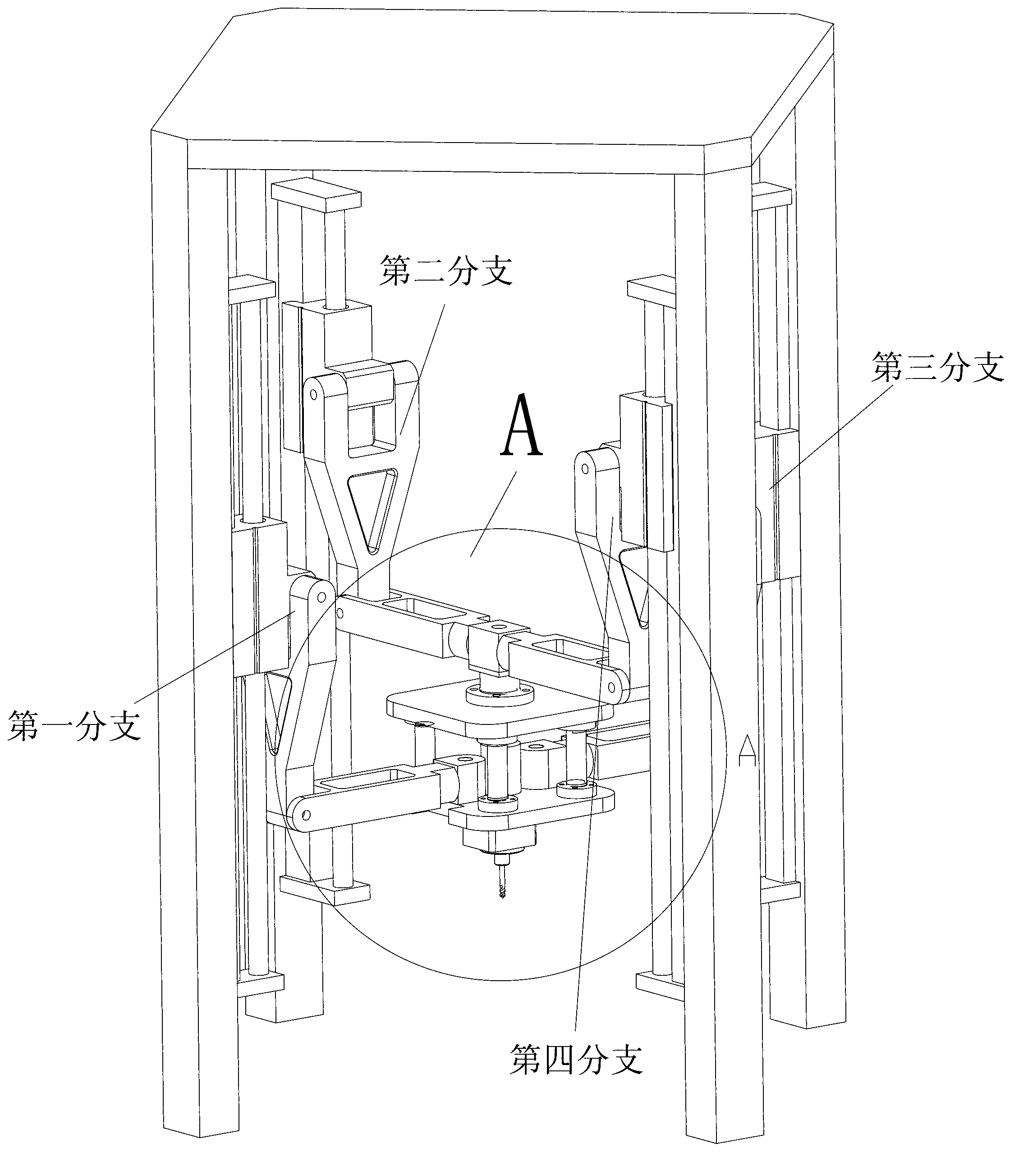

[0022] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

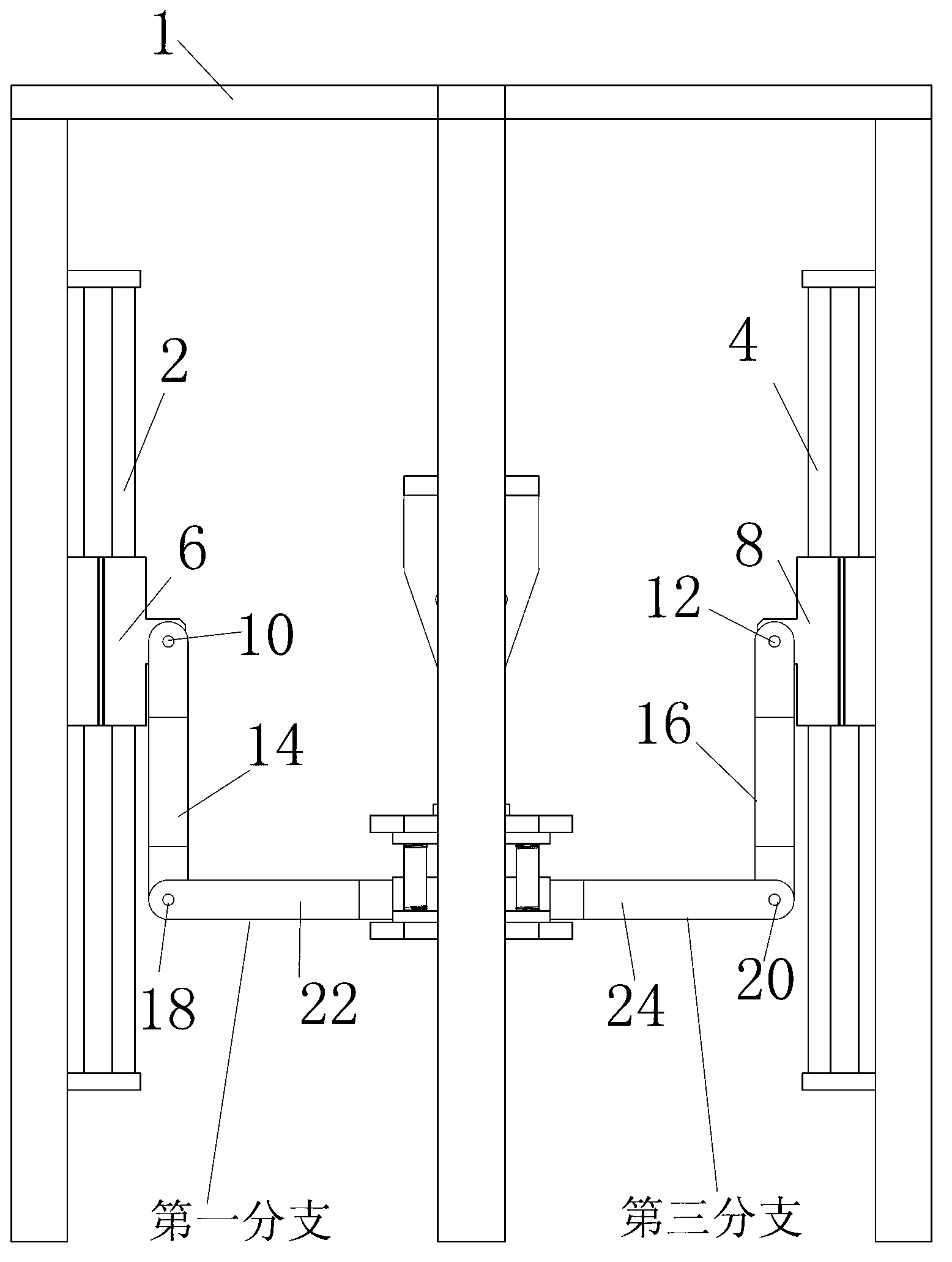

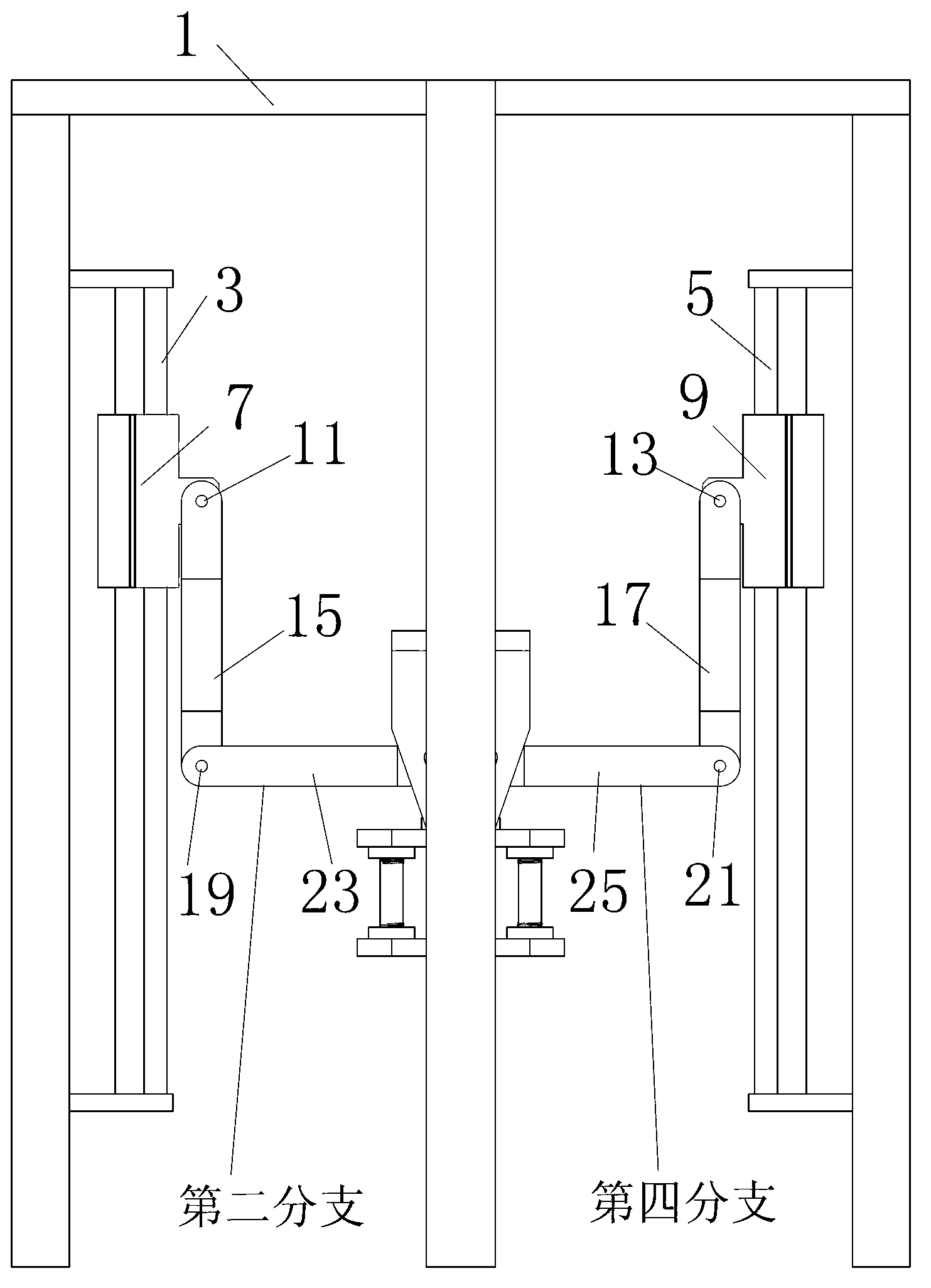

[0023] figure 1 and figure 2 As shown, the four branches of the mechanism are symmetrically distributed in pairs (the first branch, the second branch, the third branch and the fourth branch surround the circumference of the upper platform in the clockwise direction, or surround the uniform distribution in the counterclockwise direction. cloth on the circumference of the upper platform). The guide rails and leading screws in the four branches are all installed on the frame, and their axes are all perpendicular to the ground. The slider 6 of branch 1 slides and fits with the guide rail, and is driven by the lead screw 2 through the threaded structure (the slider is provided with a nut suitable for the thread of the lead screw; the same below), and the slider 6 and the connecting rod 14 pass through the rotating pair 10 Connect, connecting rod 14 and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com